A vibration-absorbing structure of an angular displacement sensor

An angular displacement sensor, connecting block technology, applied in the direction of instruments, reducing undesired effects, measuring devices, etc., can solve the problems of angular displacement sensor output fluctuation, threat to flight safety, pilot misjudgment, etc., to avoid output fluctuation, The effect of ensuring flight safety and ensuring output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

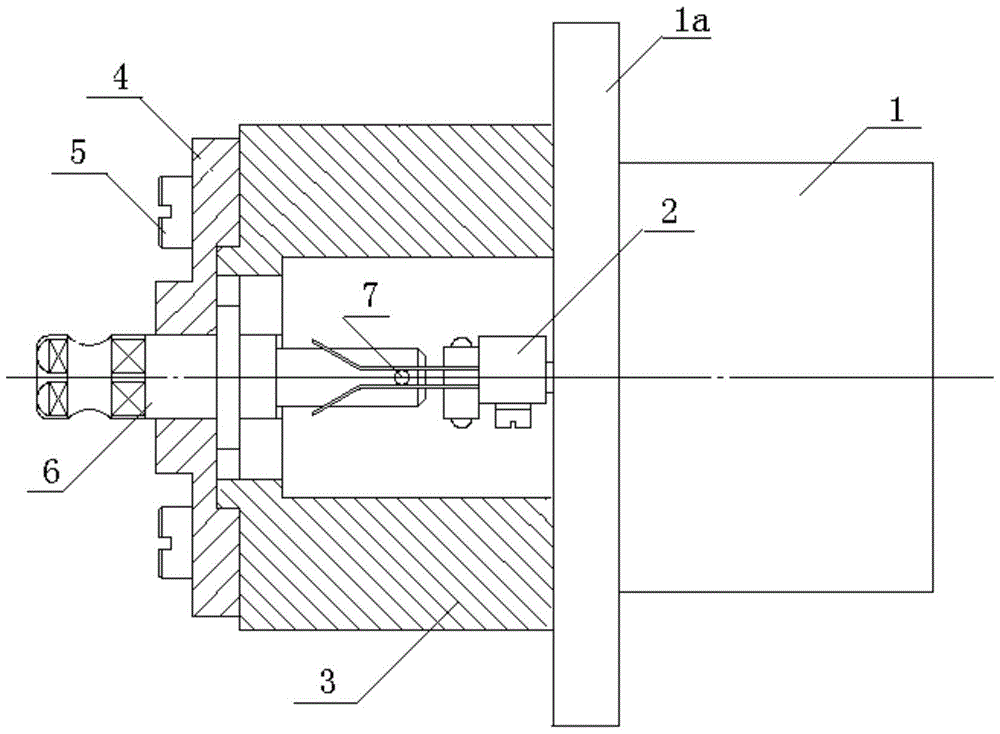

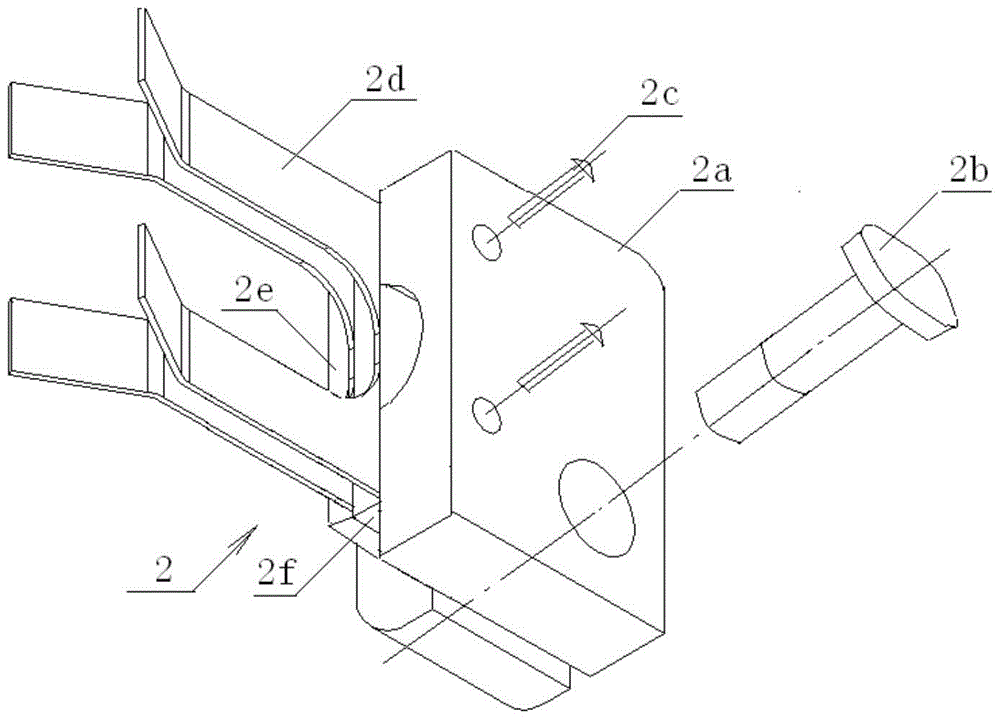

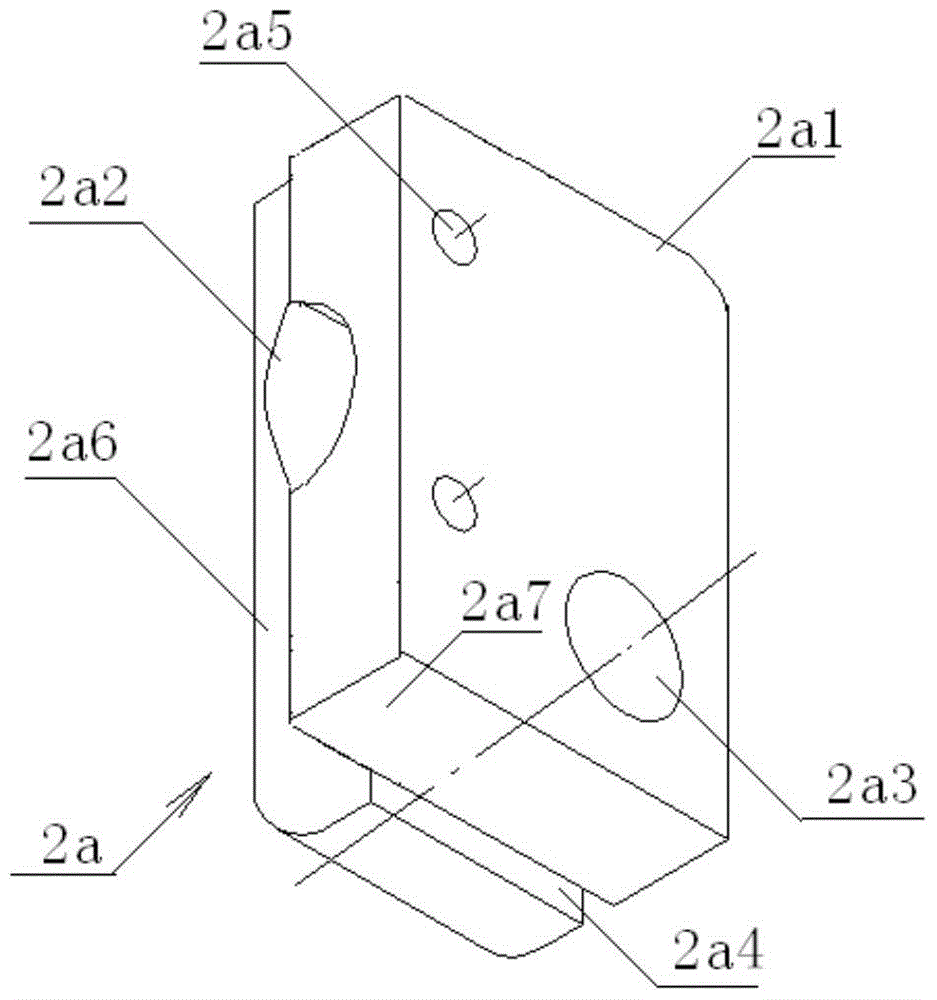

[0010] The present invention will be described in further detail below. see Figure 1 to Figure 4 , a shock absorbing structure for an angular displacement sensor, comprising an angular displacement sensor 1 with a flange 1a, the output shaft of the angular displacement sensor 1 protrudes from the center of the flange 1a; it is characterized in that: there is a fork assembly 2. The shock absorbing mechanism composed of protective cover 3, end cover 4, end cover screw 5, lead-out shaft 6 and pin shaft 7; A shift fork piece 2d, an outer baffle plate 2e and an inner baffle plate 2f; the connection block 2a has a cuboid outline, and there is a through output shaft installation hole 2a2 between the left surface and the right surface of the connection block 2a. On the lower surface 2a1 of 2a, there is a through hole 2a3 below the output shaft installation hole 2a2, and between the left surface and the upper surface of the connecting block 2a, there is a notch 2a6 with a rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com