Composite PID fuzzy control method applied to transformer cooling system

A technology of fuzzy control and cooling system, applied in the direction of adaptive control, general control system, non-electric variable control, etc., can solve the problem that the parameter change process cannot be adjusted in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

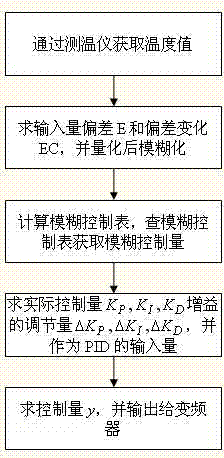

[0028] refer to figure 1 , the control method of the present invention comprises the following steps:

[0029] Step S101, obtaining a temperature value through a thermometer;

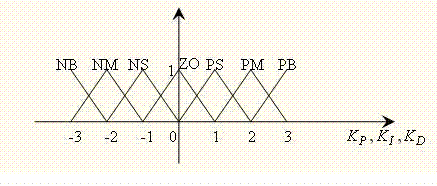

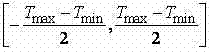

[0030] Step S102, calculate the input quantity deviation E and deviation change EC, and fuzzify after quantization;

[0031] Step S103, calculating the fuzzy control table, checking the fuzzy control table to obtain the fuzzy control amount;

[0032] Step S104, find the actual control quantity , , , and as the input of PID;

[0033] Step S105, find the control quantity , and output to the inverter.

[0034] In the step S101, a temperature value is obtained by a temperature measuring instrument, specifically, the temperature value is the transformer oil temperature measured in real time by the temperature measuring instrument.

[0035] The step S102 is to calculate the input deviation E and the deviation change EC, quantify and then fuzzify, specifically, compare the transformer oil temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com