A kind of tomato film-coated composite antistaling agent and preparation method thereof

A composite fresh-keeping and film-coating technology, which is applied in the fields of fruit and vegetable preservation, protection of fruits/vegetables with a coating protective layer, and food preservation. It can solve the problems of high weight loss rate of tomatoes and poor film-forming performance of tomato preservatives, and achieve high Commercial value, improved appearance, strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

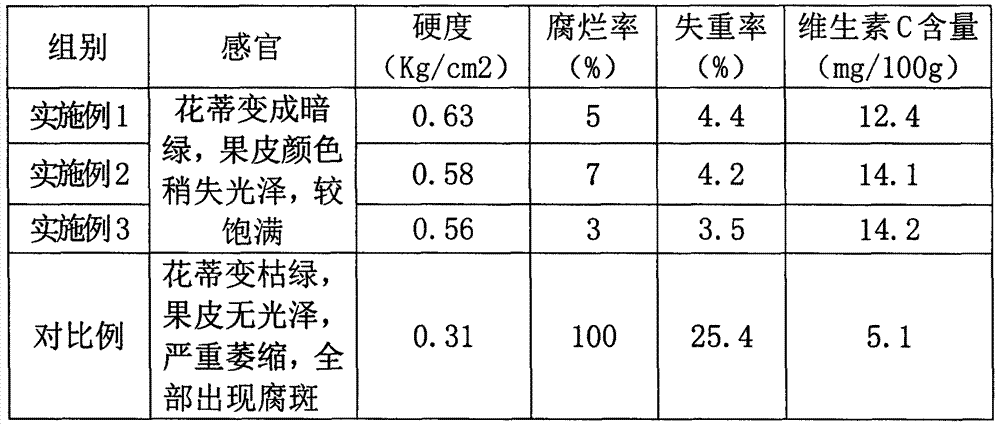

Examples

Embodiment 1

[0020] (1) Preparation of gardenia extract

[0021] Soak gardenia in clear water for 1 hour, remove and dry, then add 5 times the amount of water to the gardenia, boil for 20 minutes, filter, add 5 times the amount of water to the filter residue, boil for 20 minutes, filter, combine The two filtrates are the gardenia extract.

[0022] (2) Mixing

[0023] (1) According to 0.5% lecithin, 0.05% phytic acid, 1% polyoxyethylene sorbitan monooleate, 0.05% konjac mannan, 0.1% xanthan gum, 0.2% sodium chloride, 0.3% nanometer Silicon oxide, 0.5% glycerol, 0.3% sodium hexametaphosphate, and the balance is the proportion of gardenia extract. After weighing each component, mix nano silicon dioxide and sodium hexametaphosphate and grind it in a mortar 5~10min.

[0024] (2) Mix the ground silicon dioxide, sodium hexametaphosphate, glycerol, and gardenia extract evenly, and then ultrasonically treat it for 10 minutes under vacuum to obtain a dispersion.

[0025] (3) After adding lecithi...

Embodiment 2

[0027] (1) Preparation of gardenia extract

[0028] Soak gardenia in clear water for 1.2 hours, remove and dry, then add 6 times the amount of water to the gardenia, boil for 25 minutes, filter, add 6 times the amount of water to the filter residue, boil for 25 minutes, and filter. Combine the two filtrates to obtain the gardenia extract.

[0029] (2) Mixing

[0030] (1) According to 0.7% lecithin, 0.08% phytic acid, 1.5% polyoxyethylene sorbitan monooleate, 0.06% konjac mannan, 0.2% xanthan gum, 0.3% sodium chloride, 0.4% nanometer Silicon oxide, 0.6% glycerol, 0.4% sodium hexametaphosphate, and the balance is the ratio of gardenia extract. After weighing each component, mix nano silicon dioxide and sodium hexametaphosphate and grind it in a mortar 8min.

[0031] (2) Mix the ground silicon dioxide, sodium hexametaphosphate, glycerol, and gardenia extract evenly, and then ultrasonically treat it for 12 minutes under vacuum to obtain a dispersion.

[0032] (3) After adding ...

Embodiment 3

[0034] (1) Preparation of gardenia extract

[0035] Soak gardenia jasmine in clean water for 2 hours, remove and dry, then add 8 times the amount of water to the gardenia, boil for 30 minutes, filter, add 8 times the amount of water to the filter residue, boil for 30 minutes, filter, combine The two filtrates are the gardenia extract.

[0036] (2) Mixing

[0037] (1) According to 1% lecithin, 0.1% phytic acid, 2% polyoxyethylene sorbitan monooleate, 0.1% konjac mannan, 0.3% xanthan gum, 0.4% sodium chloride, 0.5% nanometer Silicon oxide, 1% glycerol, 0.5% sodium hexametaphosphate, and the balance is the ratio of gardenia extract. After weighing each component, mix nano silicon dioxide and sodium hexametaphosphate and grind it in a mortar 10min.

[0038] (2) Mix the ground silicon dioxide, sodium hexametaphosphate, glycerol, and gardenia extract evenly, and then ultrasonically treat it for 15 minutes under vacuum to obtain a dispersion.

[0039] (3) After adding lecithin, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com