Heat-resisting ceramic container with ceramic screw connection seat and manufacture method of heat-resisting ceramic container

A ceramic container and connecting seat technology, which is applied to cooking utensils, special materials for cooking utensils, household appliances, etc., can solve the problems of poor thermal conductivity, easy air leakage and falling off of connecting holes, and achieve strong gap sealing and wide application range , the effect of reasonable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

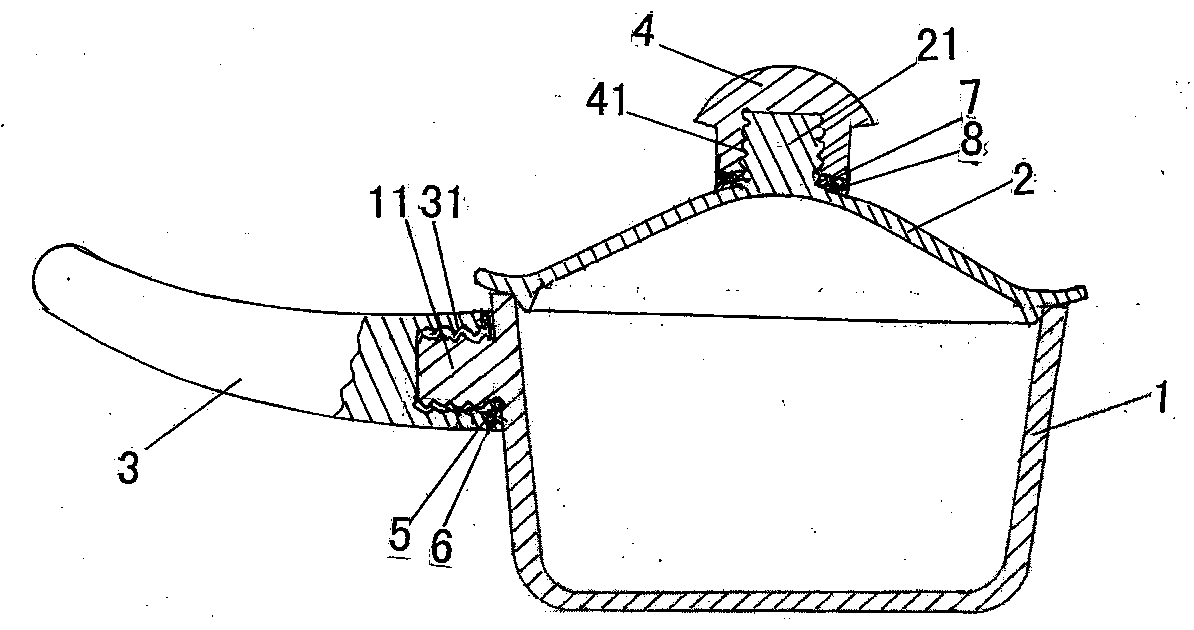

[0029] Such as figure 1 Shown: a ceramic container with a ceramic screw connection seat, including a ceramic container body 1 and a ceramic cover 2, a handle 3 is provided on one side of the ceramic container body 1, and a handle 4 is provided on the top of the ceramic cover. One side of the ceramic container body 1 and the top of the ceramic cover body 2 are provided with ceramic screws 11 and 21, the ceramic container body 1 and the ceramic screw 11 are of an integrated structure, and the ceramic cover body 2 and the ceramic screw 21 are of an integrated structure The handle 3 and the handle 4 are made of ceramic material, and screw holes 31 and 41 are provided at their connection, the screw hole 31 of the handle is screwed with the screw 11 of the ceramic container body, and a Silicone gasket 5 and spring gasket 6, the screw hole 41 of the handle is screwed with the screw 21 of the cover, and a silicone gasket 7 and a gasket 8 are installed at its contact.

[0030] The met...

Embodiment 2

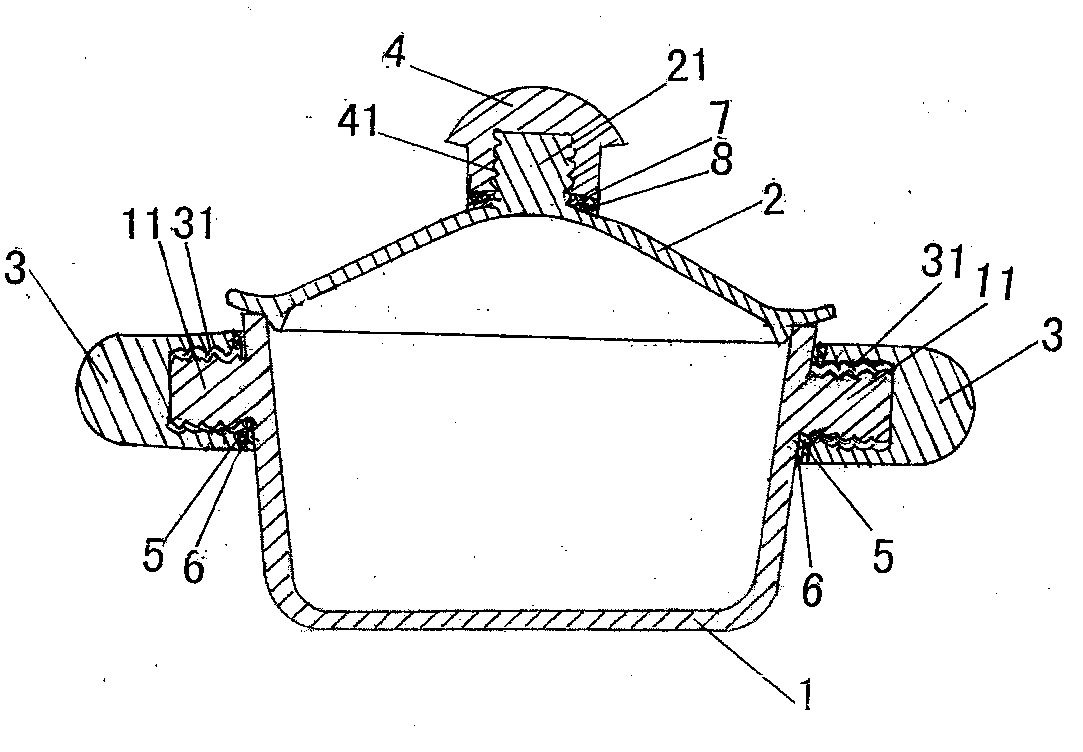

[0045] Such as figure 2 Shown: a ceramic container with a ceramic screw connection seat, including a ceramic container body 1 and a ceramic cover 2, handles 3 are provided on both sides of the ceramic container body 1, and a handle 4 is provided on the top of the ceramic cover. Both sides of the ceramic container body 1 and the top of the ceramic cover body 2 are provided with ceramic screws 11 and 21, the ceramic container body 1 and the ceramic screw 11 are integrally structured, and the ceramic cover body 2 and the ceramic screw 21 are integrally structured ; The handle 3 and the handle 4 are made of thermosetting plastic material, and screw holes 31 and 41 are provided at their joints, and other structural features are the same as those in Example 1.

[0046] The above-mentioned manufacturing method of the ceramic container provided with the ceramic screw connection seat:

[0047] Step (5) Use thermosetting plastics to make handles and handles on both sides, and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com