A method for manufacturing a heat-resistant ceramic pot provided with a connecting seat

A manufacturing method and connecting seat technology, which are applied in the direction of household appliances, kitchen appliances, special materials for cooking utensils, etc., can solve the problems of falling off, easy air leakage of connecting holes, poor thermal conductivity, etc., and achieve strong sealing, wide application range, Reasonable connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

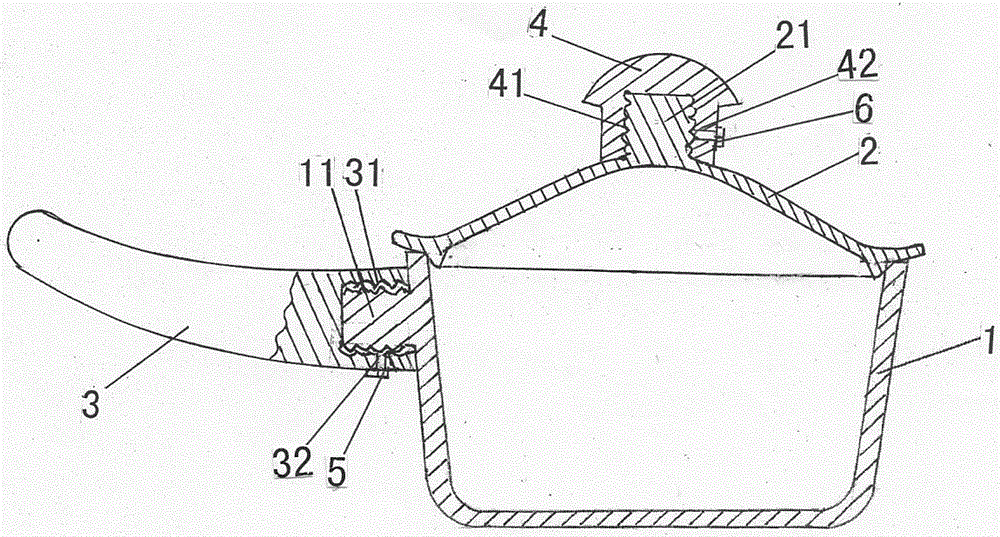

[0028] Such as figure 1 Shown: a heat-resistant ceramic pot with a connecting seat, including a ceramic pot body 1 and a ceramic pot cover 2, a handle 3 is provided on one side of the ceramic pot body 1, and a handle 4 is provided on the top of the ceramic pot cover One side of the ceramic pot body 1 and the top of the ceramic pot cover 2 are provided with ceramic screws 11 and 21, the ceramic pot body 1 and the ceramic screws 11 are in one structure, the ceramic pot cover 2 and ceramic The screw 21 has an integral structure; the handle 3 and the handle 4 are made of ceramic material, and screw holes 31 and 41 are provided at their joints, the screw hole 31 of the handle is screwed with the screw 11 of the ceramic pot body, and the The screw hole 41 of the hand is screwed with the screw 21 of the pot cover, and a fastening device is provided at its junction. Small screw holes 32 and 42 are respectively installed with a small screw 5 and 6 on the small screw holes 32 and 42, a...

Embodiment 2

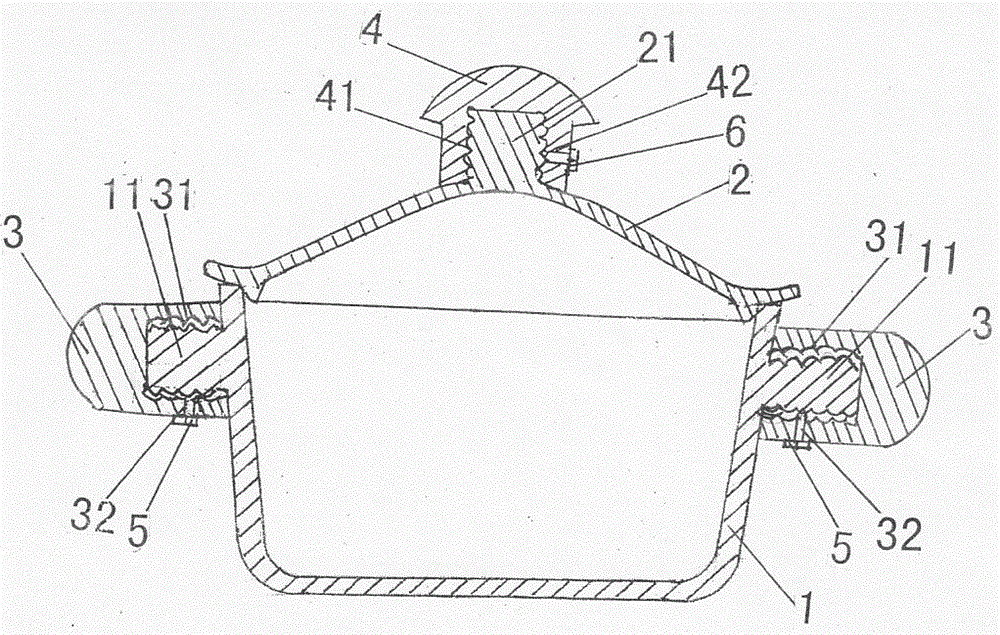

[0044] Such as figure 2 Shown: a heat-resistant ceramic pot with a connecting seat, including a ceramic pot body 1 and a ceramic pot cover 2, handles 3 are provided on both sides of the ceramic pot body 1, and a handle 4 is provided on the top of the ceramic pot cover The two sides of the ceramic pot body 1 and the top of the ceramic pot cover 2 are provided with ceramic screws 11 and 21, the ceramic pot body 1 and the ceramic screws 11 are integrally structured, and the ceramic pot cover 2 and ceramic The screw 21 has an integrated structure; the handle 3 and the handle 4 are made of ceramic materials, and screw holes 31 and 41 are provided at their joints, and the screw holes 31 of the handle 3 on both sides are screwed with the screws 11 of the ceramic pot body. Then, other structural features are the same as in Embodiment 1.

[0045] Its manufacture method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com