Device for cleaning chemical agitator

A technology for cleaning device and mixing tank, applied in the chemical industry, can solve the problems of residual raw materials, incomplete flushing, non-contact, etc., and achieves the effects of good cleaning effect, simple structure, and easy processing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

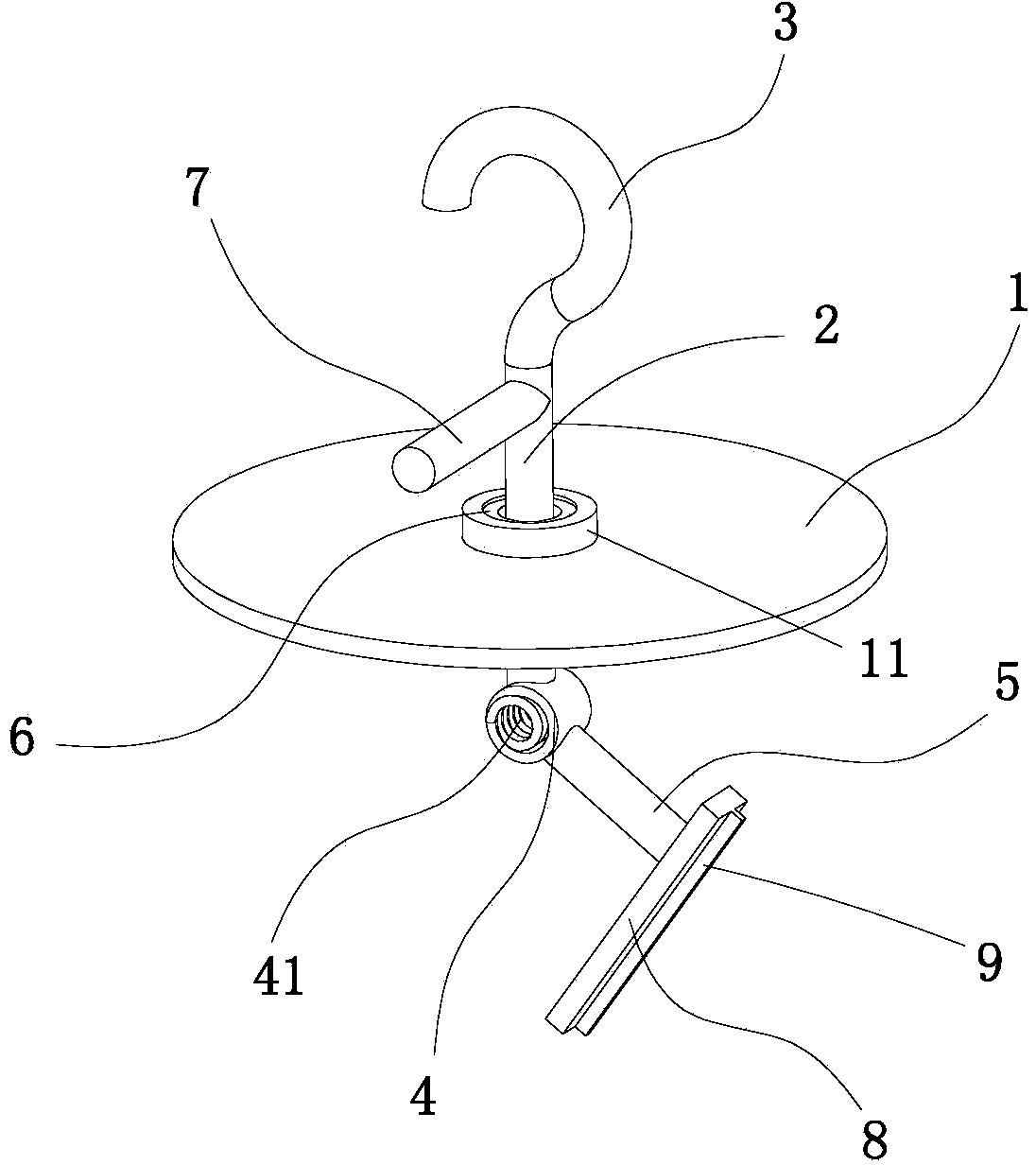

[0014] Such as figure 1 As shown, the cleaning device of the chemical mixing tank of this embodiment includes a scraper 1, the outer diameter of the scraper 1 is slightly smaller than the inner diameter of the mixing tank, and when the scraper 1 is inserted, it forms a clearance fit with the mixing tank; the scraper 1 There is a boss 11 in the center of the boss 11, and a rotating rod 2 is installed in the boss 11 by means of a bearing 6 to rotate the axial direction. The upper end of the rotating rod 2 is connected with a hand-held hook 3. The side is radially connected to the crossbar 7, and the crossbar 7 is convenient to rotate the rotating rod 2; the lower end of the rotating rod 2 is hinged to the scraper rod 5 by means of the connecting sleeve 4, and a torsion spring 41 is arranged in the connecting sleeve 4; the scraping rod 5 is r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap