Clothes treatment equipment

A technology of clothes processing equipment and outer cylinder, which is applied in other washing machines, textiles and papermaking, household appliances, etc. It can solve the problems of manual installation and disassembly, failure to realize automatic cylinder cleaning, troublesome use, etc., and achieve the effect of ensuring cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

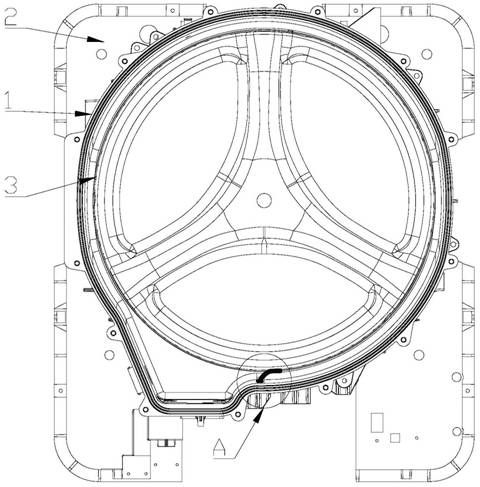

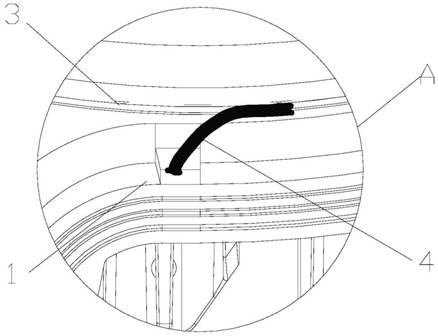

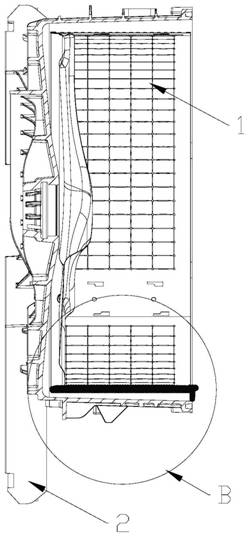

[0041] Such as Figure 1-8 As shown, in this embodiment, the axis of the outer cylinder 1 extends horizontally, the inner cylinder 3 is arranged coaxially with the outer cylinder 1, and the cleaning element 4 is connected to the bottom of the wall of the outer cylinder 1, and at least part of the density is lower than that of the washing water. Density, so that the cleaning piece 4 is in contact with the outer wall of the inner cylinder 3 for cleaning under the buoyancy of the washing water.

[0042] Wherein, the axis of the outer cylinder 1 extends horizontally, and the inner cylinder 3 is arranged coaxially with the outer cylinder 1, that is, the clothes processing device is a drum type clothes processing device. Preferably, the clothes processing device is a wall-mounted clothes processing device. Specifically, at least one radially protruding hanging ear 2 is provided on the wall of the outer cylinder 1, and the hanging ear 2 is assembled with the wall.

[0043] In some e...

Embodiment 2

[0045] Such as Figure 1-8 As shown, the difference between this embodiment and the above-mentioned first embodiment is that the cleaning element 4 is a bar-shaped structure, one end of which is connected to the outer cylinder 1, and the other end is freely arranged. The length of each cleaning piece 4 is greater than or equal to the distance between the outer cylinder 1 and the inner cylinder 3.

[0046] Wherein, a plurality of cleaning parts 4 are close to each other or are spaced apart from each other by a certain distance.

[0047] In some embodiments, only the density of the free end of the cleaning element 4 is less than the density of the washing water, so that the end of the cleaning element 4 is in contact with the outer wall of the inner cylinder 3 for cleaning. In some embodiments, only the density of the middle section of the cleaning element 4 is less than that of the washing water. Density, so that the side of the cleaning piece 4 is in contact with the outer wa...

Embodiment 3

[0052] Such as Figure 1-8 As shown, the difference between this embodiment and the first and second embodiments above is that the cleaning member 4 is a sheet-like structure, and its first edge is connected with the outer cylinder 1 and is arranged on the same plane as the axis of the outer cylinder 1. The second edge opposite to the edge is freely arranged, and the length between the first edge and the second edge of the cleaning element 4 is greater than or equal to the distance between the outer cylinder 1 and the inner cylinder 3 .

[0053] Preferably, the first edge of the cleaning element 4 is arranged on the same vertical plane as the axis of the outer cylinder 1 .

[0054] Similarly, in some embodiments, only the density of the second edge of the cleaning piece 4 is less than the density of the washing water, so that the edge of the cleaning piece 4 is in contact with the outer wall of the inner cylinder 3 for cleaning. In some embodiments, only the density of the mid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap