Conversion type automobile bumper

A technology for automobile bumpers and conversion racks, applied to bumpers and other directions, can solve problems such as poor protection ability, single function, and simple structure, and achieve the effects of mitigating shock waves, improving driving safety, and enhancing overall protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

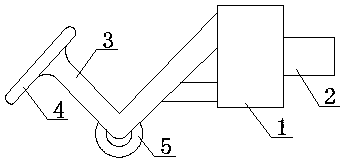

[0011] Such as figure 1 It is a structural schematic diagram of the present invention, a converted automobile bumper, including a bumper body 1 and a bracket 2, the bracket 2 is located inside the bumper body 1, and a conversion rack 3 is arranged on the bumper body 1. Conversion frame 3 is " V " shape, and rear end is connected on the bar body 1 . The front end of the conversion frame 3 is provided with a guide plate 4, and the bottom is provided with a support wheel 5.

[0012] A "V"-shaped conversion frame 3 is set at the front portion of the lever body 1 to form a lever structure. The front end of the conversion frame 3 is provided with a guide plate 4, and the bottom is provided with a support wheel 5. When a collision occurs, the horizontal impact force is converted into a downward pressure under the action of the guide plate 4, and then the support wheel 5 is used as a fulcrum to further transform into a lifting force on the car body by using the principle of leverage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com