On-line measuring method of tread winding thickness based on image

A measurement method and tread technology, applied to measuring devices, instruments, optical devices, etc., can solve problems such as low production efficiency, inability to obtain tread line thickness information at one time, and inability to block the measuring head, so as to improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

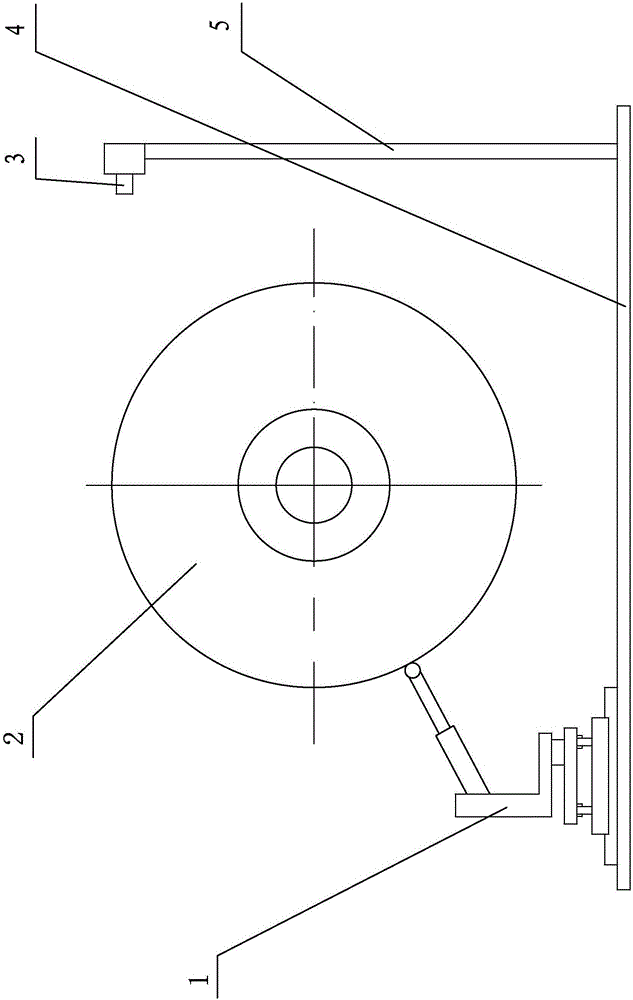

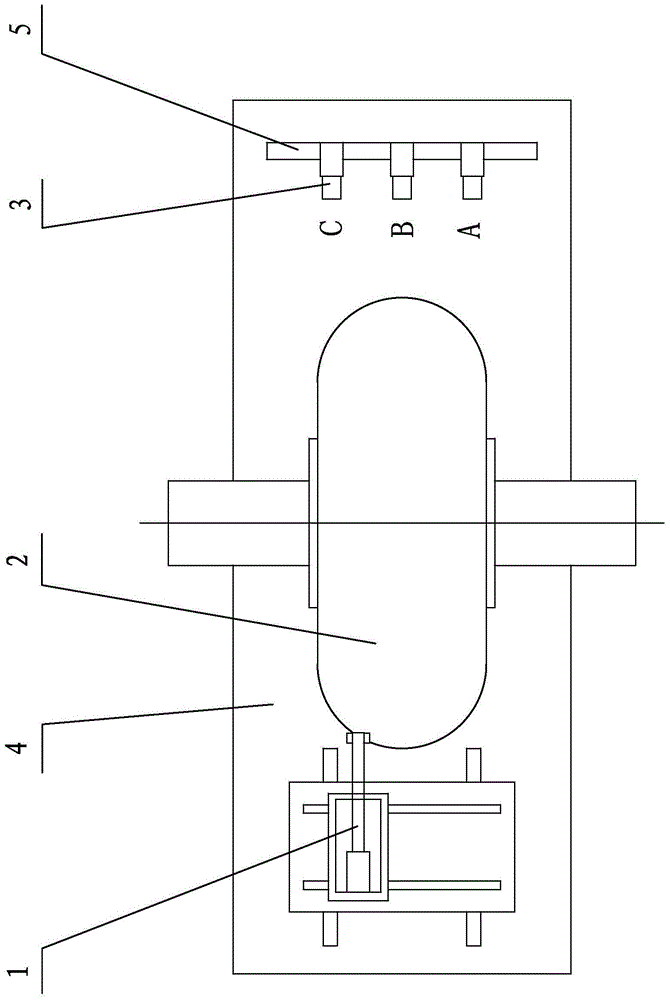

[0021] Tire 2 is vertically installed in place on the support 4 of tire winding machine by horizontal roller shaft, and the winding mechanism 1 of tire winding machine is located on the support 4 of tire 2 left side bottoms.

[0022] Under the above-mentioned production conditions, the image-based online measurement method for tread winding thickness of the present invention is carried out according to the following steps:

[0023] 1. The camera 3 is placed. The support 4 on the right side of the tire 2 is provided with a vertical support 5, and on the same horizontal plane of the top of the support 5, three cameras 3 with the same model specifications are arranged along the axial direction of the tire 2 (the wider the width of the tire 2, the further Increase the number of cameras 3), three cameras 3 are placed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com