Hydraulic over-obstacle ground wire traveling gear

A walking device and hydraulic technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of heavy disassembly and assembly, low maintenance efficiency, and changing positions, and achieve high safety and stability, improved maintenance efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

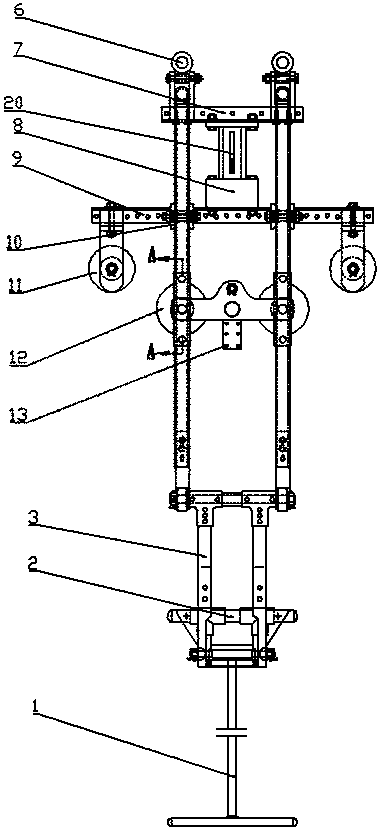

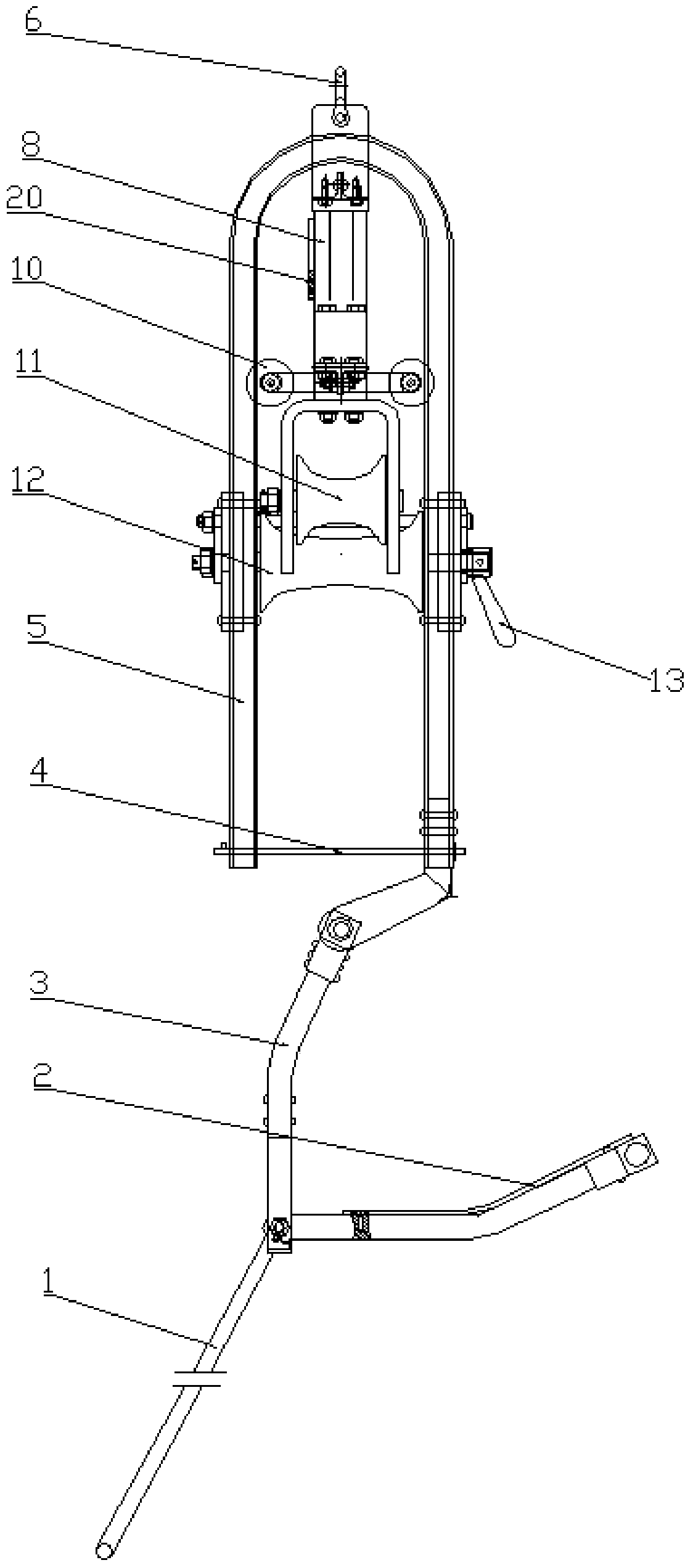

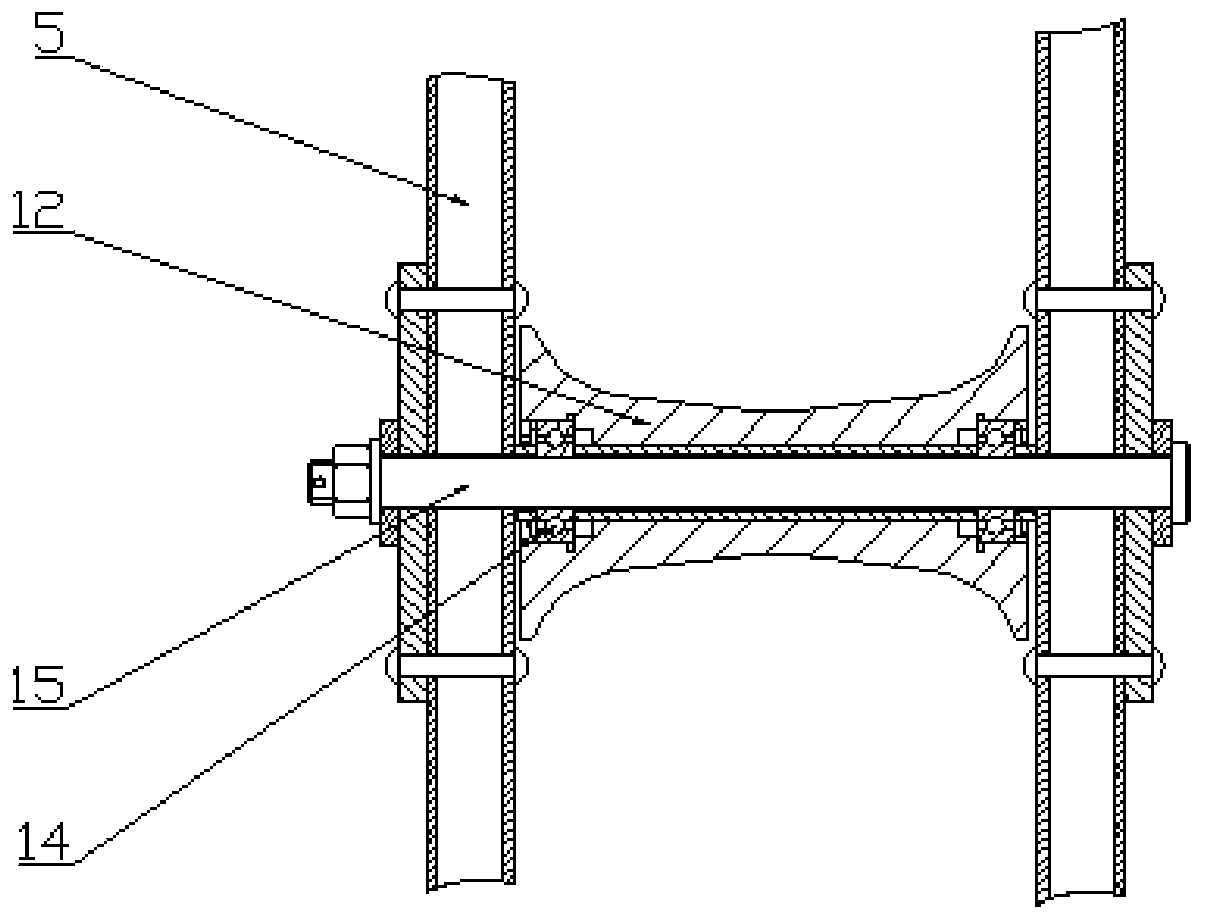

[0016] figure 1 It is a hydraulic obstacle-crossing ground wire walking device (hereinafter referred to as a flying car), including two n-shaped main wheel frames 5, the middle of the n-shaped main wheel frame is provided with a main axle 15 connected to both sides of the frame, and the main wheels 12 pass Bearing 14 is mounted on the main axle ( image 3 ).

[0017] in figure 2 Among them, the upper ends of the two n-shaped main wheel frames 5 are fixed to each other through the top beam 7, the two main wheels 12 are also connected by connecting rods, and a brake valve 13 is sleeved between the two main wheels 12.

[0018] A stop pin 4 parallel to the axis of the main wheel is provided at the lower end of the main wheel frame 5, and the stop pin 4 can be opened and locked to ensure that the line passes between the main wheel and the stop pin.

[0019] The lower end of the wheel frame 5 is hinged with the seat frame 3, a seat 2 is provided on the seat frame 3, and the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com