Automatic strong paste type material squeezing line

A material and automatic technology, applied in the fields of food science, food forming, application, etc., can solve the problems of low degree of automation, cumbersome process, time-consuming and labor-intensive, etc., and achieve the effect of improving production efficiency, simplifying process steps, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

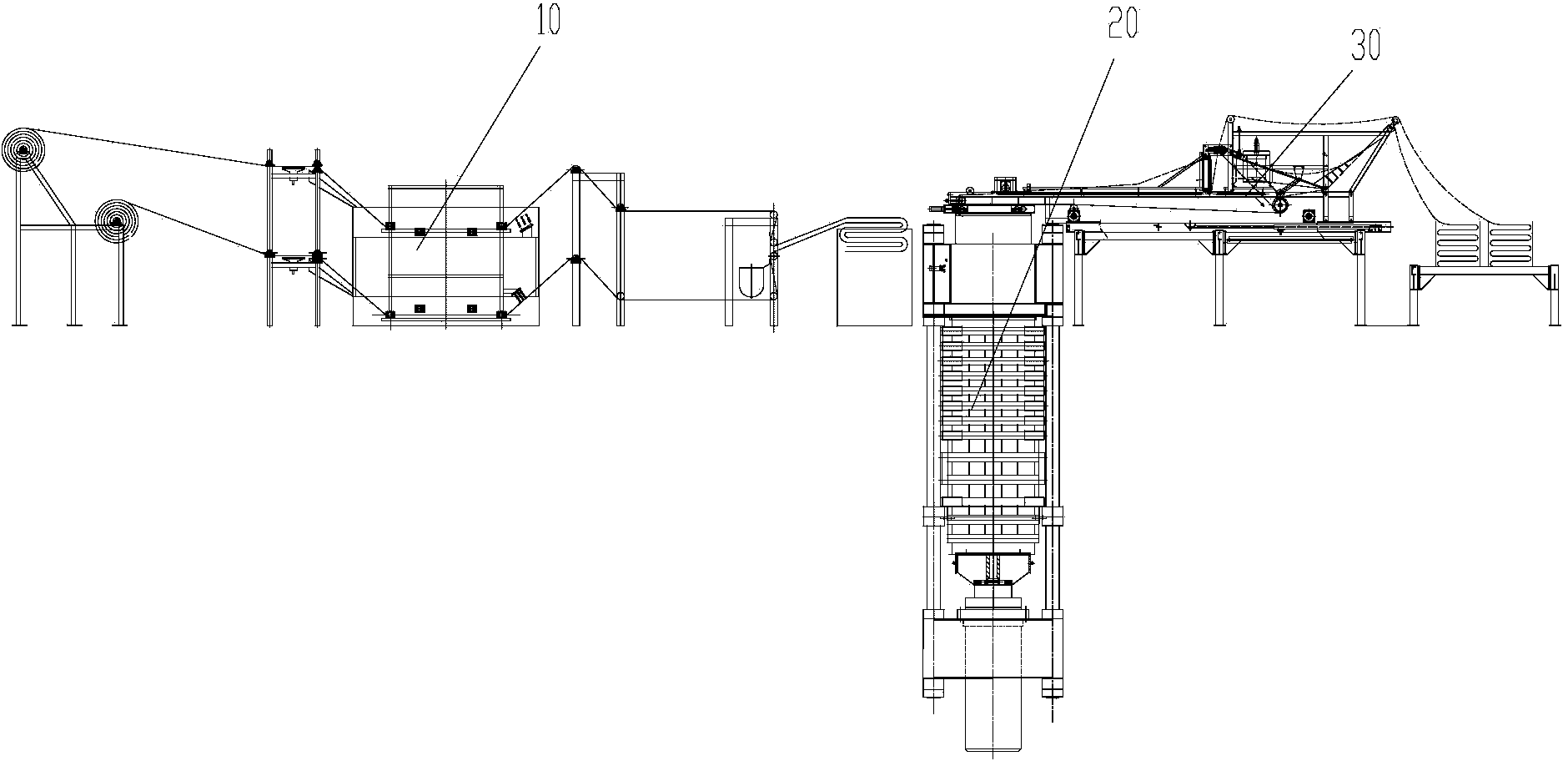

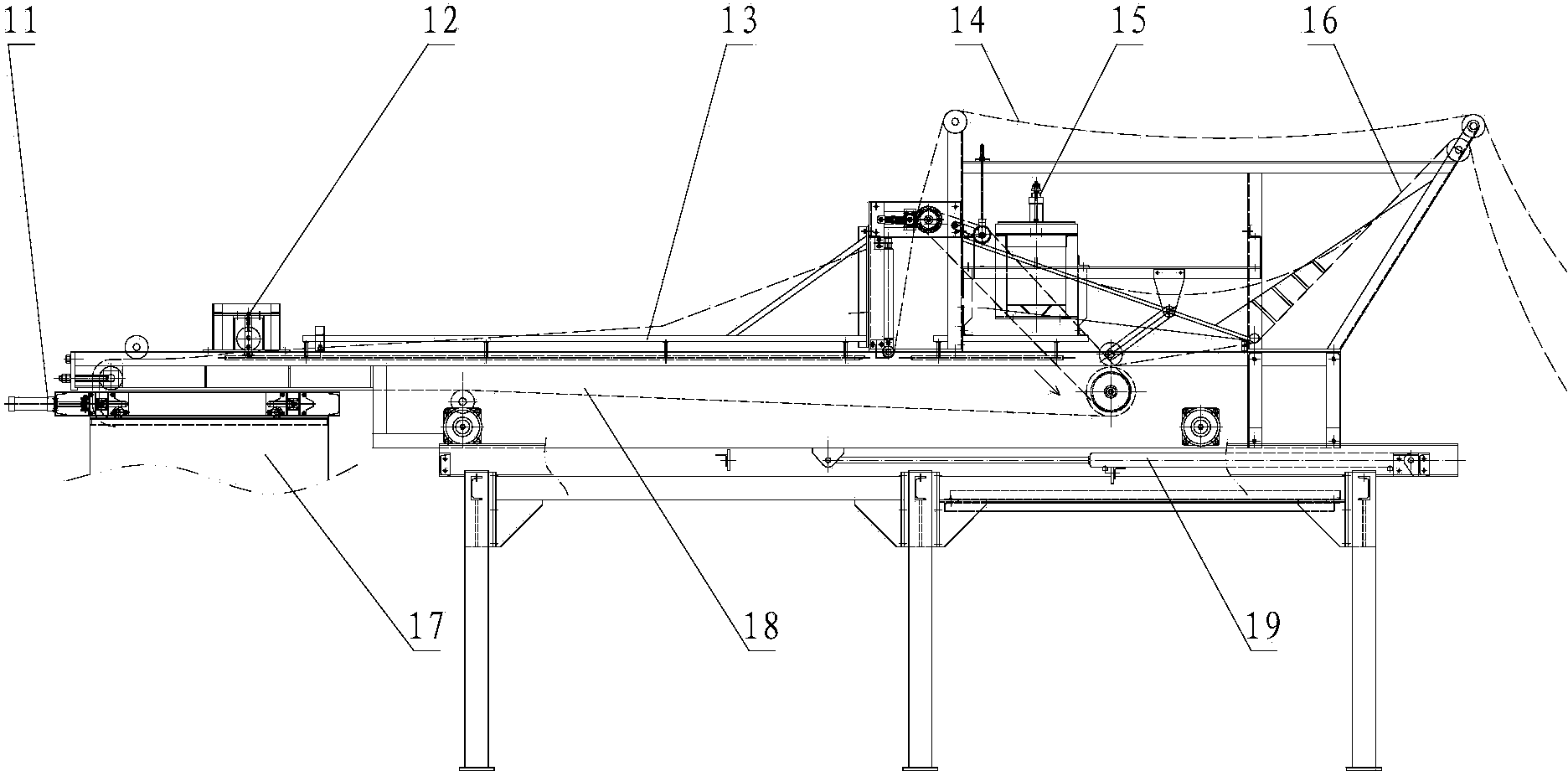

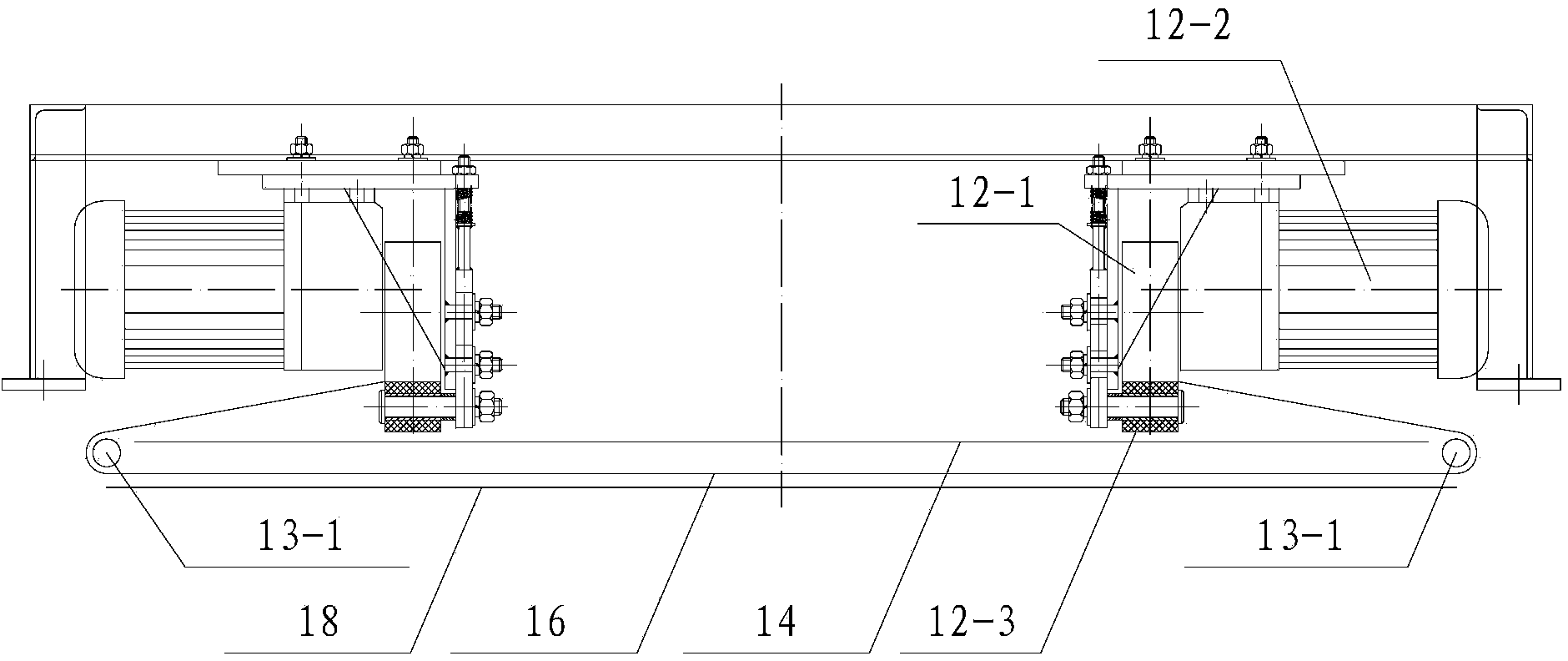

[0022] Such as Figure 1 to Figure 6 As shown, a kind of sauce-like material automatic strong pressing line of the present invention comprises automatic reciprocating sauce distributing device 10, the inverted bottom liquid press 20 that is connected with automatic reciprocating sauce distribution device 10 and the inverted bottom liquid press 20 connected to the automatic slagging and rinsing device 30, the automatic reciprocating sauce distribution device 10 includes an upper filter cloth 14, a lower filter cloth 16, a sauce filling machine 15, a reciprocating oil cylinder 19, a support platform and a stacking device 11, and the support platform is installed on the bracket , a guide rail is provided on the support, a reciprocating oil cylinder 19 is installed on the support, and the reciprocating oil cylinder 19 is connected with the support platform, and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com