Water heating pressure cooker

A technology of pressure cooker and water heating, which is applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of potential safety hazards, cumbersome work procedures, and high cost, and achieve simple and reasonable structure, simple work procedures, and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

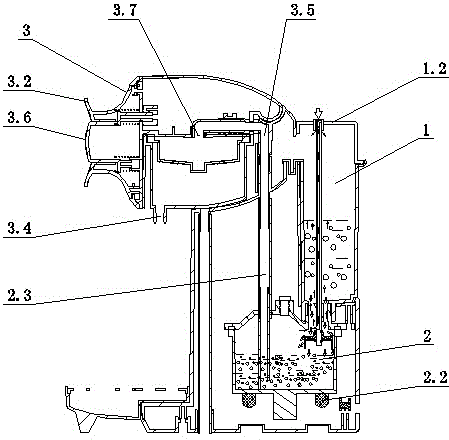

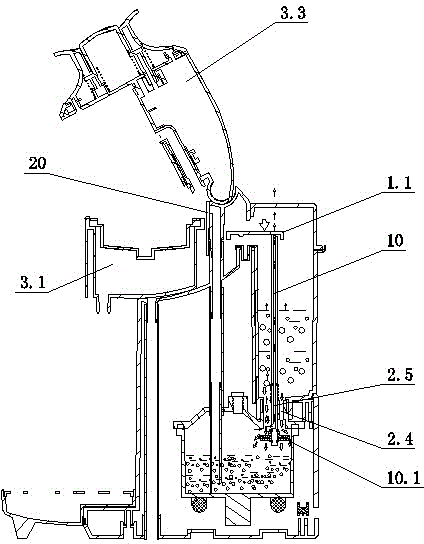

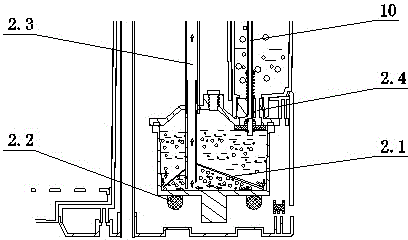

[0045] see Figure 1-6 , the hydrothermal pressure cooker includes a water tank 1, a heating cavity 2 and a brewing cavity 3, the water tank 1 has a large volume, and the heating cavity 2 has a small volume; The volume of 2 is the same. The lower part or the lower part of the water tank 1 is provided with a heating chamber 2. The upper water inlet 2.4 and the exhaust port 2.5 of the heating chamber 2 are provided. The water inlet 2.4 is connected to the water tank 1 through the heating chamber 2. The air port 2.5 controls whether water intake and exhaust are performed through the opening and closing of the water inlet switch or the water valve, so as to realize water supply and exhaust for the inside of the heating cavity 2 .

[0046] The brewing chamber 3 includes the lower body of the brewing chamber 3.1, the handle 3.2, the upper cover of the brewing chamber 3.3, the spout 3.4, the water outlet 3.5 and the button 3.6. The inner wall of the upper cover 3.3 of the brewing ch...

no. 2 example

[0056] see Figure 7-8 , this hydrothermal pressure cooker is different from the first embodiment in that: the water inlet switch or valve is a magnetic float valve 5, and the magnetic float valve includes a connecting rod 10, a seal 5.1, a float seal, a magnet 5.2 and a limiter. Bit parts; the magnetic float valve 5 is movable to set the upper part of the heating chamber 2 and is arranged on the water inlet 2.4 at the bottom of the water tank 1, its weight is less than the buoyancy of the rising water surface, and the magnetic float valve 5 top is provided with a limit device, which ensures that The magnetic float valve 5 moves up and down to realize the opening or closing of the water inlet 2.4. The magnetic float on the magnetic float valve 5 is fixed or movably connected to the connecting rod 10. The magnetic float valve 5 is a cavity structure, and the cavity is a sealed cavity or the lower part of the cavity The opening and the water surface are combined to form a relati...

no. 3 example

[0058] see Figure 9-12, this hydrothermal pressure cooker is different from the first embodiment in that: the water inlet switch or valve is a two-way valve body 6, and the two-way valve body 6 is provided with a handle 6.1, a knob central shaft and a knob outer cover, and the knob center Through-holes (6.1) are respectively set on the shaft and the outer shell of the knob, and the through-holes 6.1 on the two-way valve body 6 are respectively sealed and fixedly connected with the water inlet 2.4 and the exhaust port 2.5 corresponding to the heating chamber 2 and the water tank 1; or, the One end of the two-way valve body 6 is integrated with the water inlet 2.4 of the heating chamber 2, and the other end has a hole sealed and fixedly connected with the water inlet 2.4 of the heating chamber 2. Wherein the water inlet 2.4 and the exhaust port 2.5 are set in one, and the water inlet 2.4 and the exhaust port 2.5 are arranged at the bottom of the water tank 1 and kept at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com