Paddle telescopic stirring type slurry electrolyzer

A pulp electrolyzer and stirring technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of paralysis of electrolysis work, slowing down of mineral powder dissolution, and difficulty in increasing the concentration of metal ions, so as to reduce high energy consumption It has the effect of reducing the wear and tear of equipment, increasing the yield of electrolytic metal, and strengthening the effect of stirring and suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with accompanying drawing, the present invention is described in further detail.

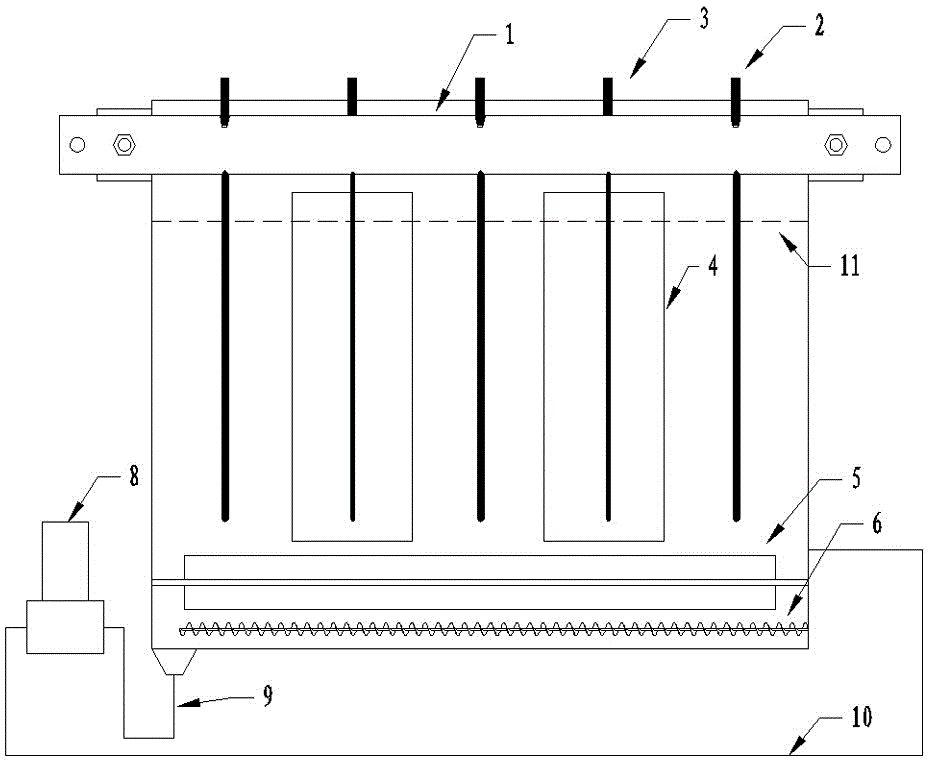

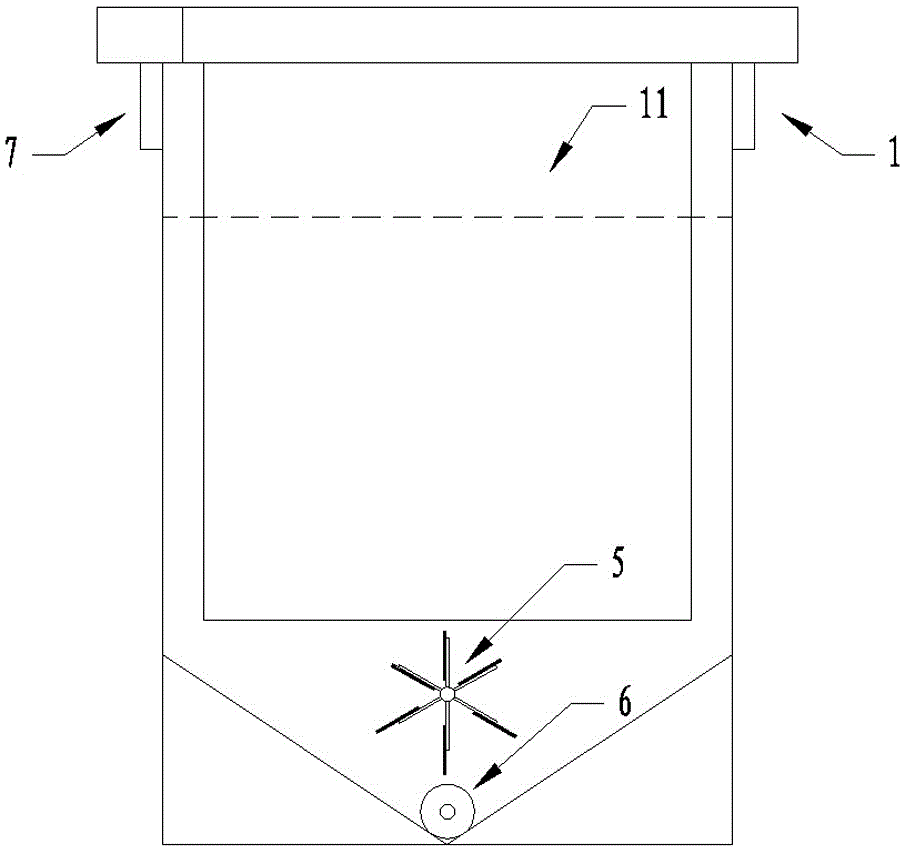

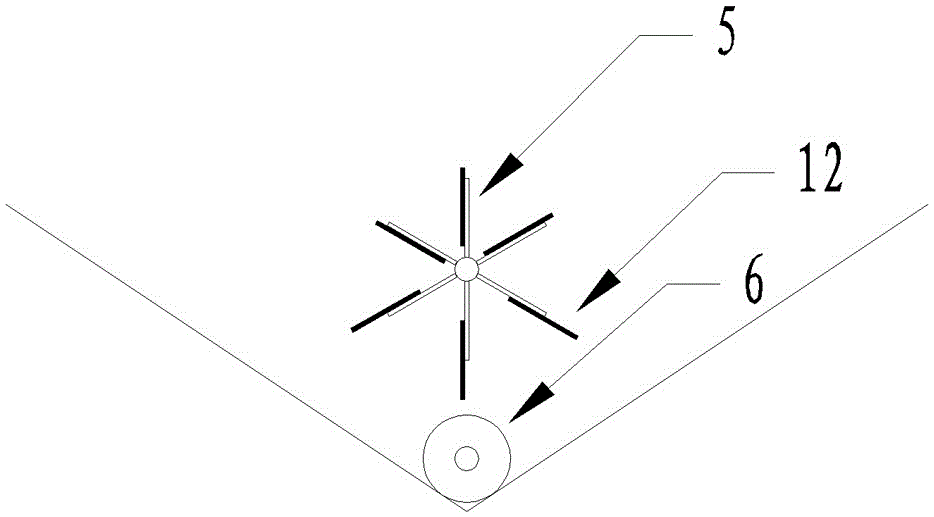

[0023] Such as figure 1 , figure 2 and image 3 The paddle telescopic agitation type pulp electrolyzer shown includes positive electrode copper strip 1, anode plate 2, negative electrode copper strip 7, cathode plate 3 and electrolytic diaphragm 4, and the pole plates 2, 3 and positive and negative electrode copper strips 1, 7 are all made of V-shaped lap joint; the middle and lower part of the electrolytic cell is provided with a horizontally arranged long-axis integrated stirring paddle 5, and the blades of the long-axis integrated stirring paddle 5 are connected with retractable movable paddles 12; the bottom of the electrolytic cell is provided with a horizontally arranged The screw conveyor 6 is provided with a cone bottom structure at the delivery end of the screw conveyor 6 , the cone bottom is connected to the wet mill 8 through the discharge pipe 9 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com