Mechanical stirring slurry electrolyzer

A slurry electrolyzer and mechanical stirring technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of electrolysis work paralysis, high energy consumption, slow speed of mineral powder dissolution, etc., to reduce high energy consumption and equipment wear , The system structure is simple and reasonable, and the effect of improving the yield of electrolytic metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Now in conjunction with accompanying drawing, the present invention is described in further detail.

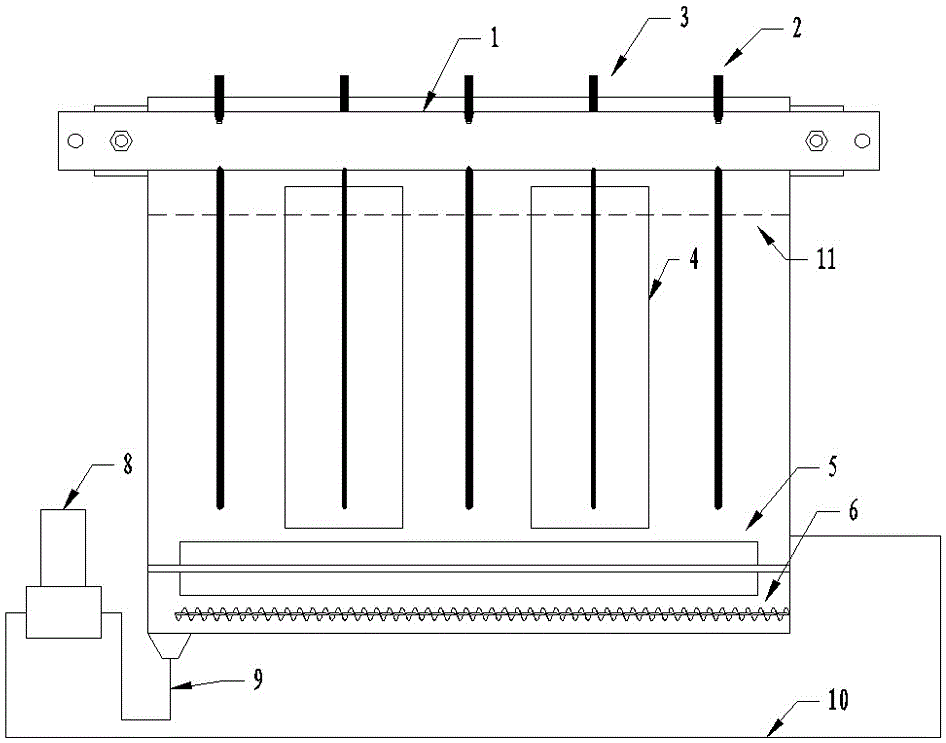

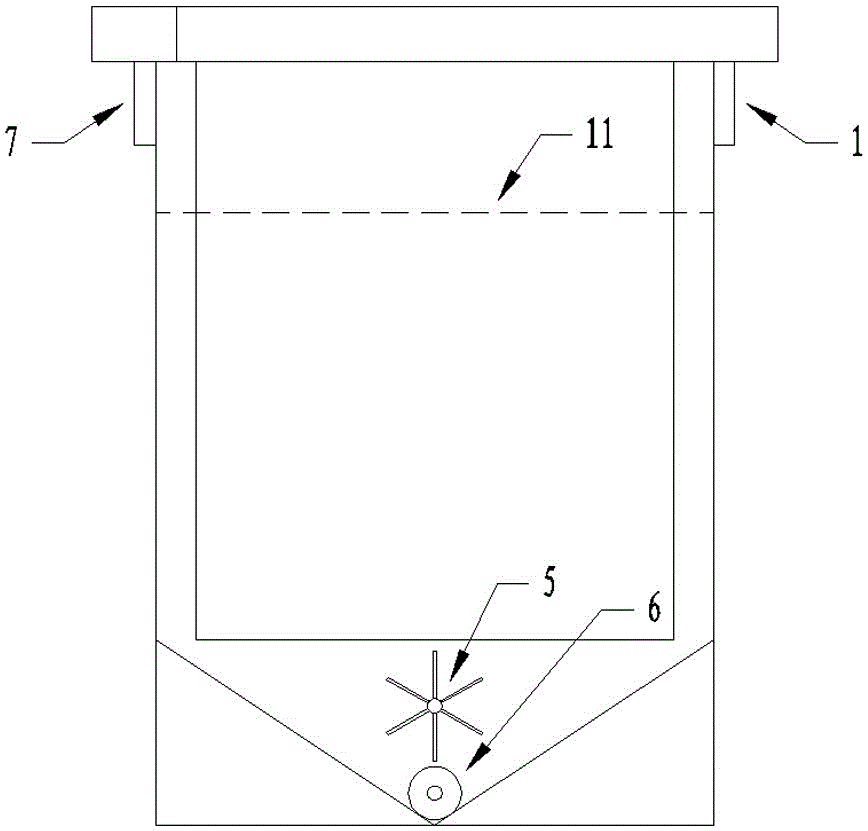

[0021] Such as figure 1 with figure 2 The mechanically agitated slurry electrolyzer shown includes positive copper strip 1, anode plate 2, negative copper strip 7, cathode plate 3 and electrolytic diaphragm 4, and the pole plates 2, 3 and positive and negative copper strips 1, 7 are all V-shaped. Overlapping; the middle and lower part of the electrolytic cell is provided with a horizontally arranged long-axis stirring paddle 5; the bottom of the electrolytic cell is provided with a horizontally arranged screw conveyor 6, and the delivery end of the screw conveyor 6 is provided with a cone bottom structure, and the cone bottom passes through The discharge pipe 9 is connected to the wet pulverizer 8, and the wet pulverizer 8 is connected to the electrolytic cell through the conveying pipe 10.

[0022] The mechanically stirred slurry electrolyzer is generally made of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com