Method for preparing monodomain (gd/y)-ba-cu-o superconducting bulk materials by liquid phase infiltration

A -ba-cu-o, superconducting block technology, applied in the field of high-temperature cuprate superconducting materials, can solve the problems of complete sample growth and unfavorable superconducting properties, long period, loss of sample liquid phase, etc., to ensure stability Growth and superconducting properties, shortening the experimental period, avoiding the effect of liquid phase loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis (Gd x Y 1-x ) 2 BaCuO 5 Precursor powder:

[0027] Take 51.5864g Gd 2 o 3 , 32.1346g Y 2 o 3 Mix well with 43.6391g BaO, 22.6399g CuO initial powder, namely Gd 2 o 3 , Y 2 o 3 The molar ratio of BaO and CuO primary powder is 0.5:0.5:1:1 (corresponding to x=0.5), and it is made by solid state reaction method (Gd 0.5 Y 0.5 ) 2 BaCuO 5 precursor powder;

[0028] (2) Preparation of liquid phase source powder:

[0029] Take 25.5000g (Gd 0.5 Y 0.5 ) 2 BaCuO 5 Precursor powder mixed with 66.7681g BaO, 57.7319g CuO initial powder, namely (Gd 0.5 Y 0.5 ) 2 BaCuO 5 The molar ratio of the precursor powder to the initial powder of BaO and CuO is 1:9:15, which is used as the liquid phase source powder;

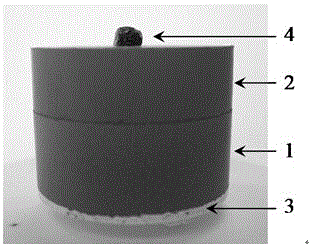

[0030] (3) Press the precursor block:

[0031] Take 10g respectively (Gd 0.5 Y 0.5 ) 2 BaCuO 5 Precursor powder and 20g liquid phase source powder were put into a cylindrical mold (diameter 26mm) and pressed into equal diameter (Gd x Y 1-...

Embodiment 2

[0041] In synthesis (Gd x Y 1-x ) 2 BaCuO 5 In the precursor powder step (1), take 11.5115g Gd 2 o 3 , 64.5375g Y 2 o 3 Mix evenly with 48.6905g BaO, 25.2605g CuO initial powder, namely Gd 2 o 3 , Y 2 o 3 The molar ratio of BaO and CuO primary powder is 0.1:0.9:1:1 (corresponding to x=0.1), and it is made by solid state reaction method (Gd 0.1 Y 0.9 ) 2 BaCuO 5 Precursor powder.

[0042] In step (2) of preparing liquid source powder, take 23.2649g (Gd 0.1 Y 0.9 ) 2 BaCuO 5 Precursor powder mixed with 67.9668g BaO, 58.7683g CuO initial powder, namely (Gd 0.1 Y 0.9 ) 2 BaCuO 5 The molar ratio of the precursor powder to the initial powder of BaO and CuO is 1:9:15, which is used as the liquid phase source powder.

[0043] In step (3) of pressing the precursor block, take 10g (Gd 0.1 Y 0.9 ) 2 BaCuO 5 Precursor powder and 17.5g liquid phase source powder were put into a cylindrical mold (diameter 26mm) and pressed into equal diameter (Gd x Y 1-x ) 2 BaC...

Embodiment 3

[0047] In synthesis (Gd x Y 1-x ) 2 BaCuO 5 In the precursor powder step (1), take 84.1278g Gd 2 o 3 , 5.8229g Y 2 o 3 Mix well with 39.5374g BaO, 20.5119g CuO initial powder, namely Gd 2 o 3 , Y 2 o 3 The molar ratio with BaO and CuO primary powder is 0.9:0.1:1:1 (corresponding to x=0.9), and it is made by solid state reaction method (Gd 0.9 Y 0.1 ) 2 BaCuO 5 Precursor powder.

[0048] In step (2) of preparing liquid source powder, take 27.6577g (Gd 0.9 Y 0.1 ) 2 BaCuO 5 Precursor powder mixed with 65.6109g BaO, 56.7314g CuO initial powder, namely (Gd 0.9 Y 0.1 ) 2 BaCuO 5 The molar ratio of the precursor powder to the initial powder of BaO and CuO is 1:9:15, which is used as the liquid phase source powder.

[0049] In step (3) of pressing the precursor block, take 10g (Gd 0.9 Y 0.1 ) 2 BaCuO 5 Precursor powder and 22.5g liquid phase source powder were put into a cylindrical mold (diameter 26mm) and pressed into equal diameter (Gd x Y 1-x ) 2 BaCuO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com