Method for preparing single-domain yttrium-barium-copper-oxygen superconducting block in liquid-phase source coated infiltration growing manner

A yttrium barium copper oxide, coating and infiltration technology is applied in the field of high-temperature copper oxide superconducting materials, which can solve the problems of insufficient liquid phase infiltration mode, difficulty in discharging liquid phase particles, shrinkage of the diameter of liquid phase source blocks, etc., and achieves improved stability. Reproducibility and repeatability, shortened experimental cycle, height reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare Y 2 BaCuO 5 Precursor powder:

[0026] Take 73.8453g Y 2 o 3 , 50.1414g BaO, 26.0133g CuO initial powder mixed evenly, namely Y 2 o 3 The molar ratio of BaO and CuO initial powder is 1:1:1, and Y is prepared by solid state reaction method 2 BaCuO 5 precursor powder;

[0027] (2) Preparation of liquid phase source powder:

[0028] Take 80.4435g BaO and 69.5565g CuO primary powder and mix evenly, that is, the molar ratio of BaO and CuO primary powder is 3:5, and the nominal composition is Ba 3 Cu 5 o 8 The mixed powder, as the liquid phase source powder;

[0029] (3) Press the precursor block:

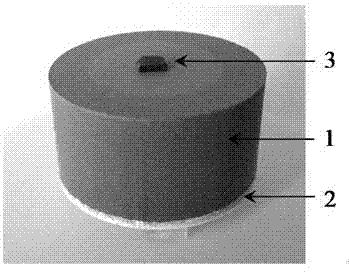

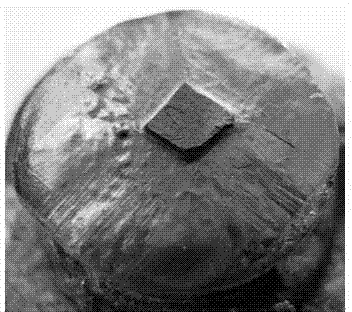

[0030] Take 6g Y 2 BaCuO 5 Put the precursor powder into a cylindrical mold 1 (16 mm in diameter) and press it into Y 2 BaCuO 5 solid phase block; the Y 2 BaCuO 5Put the solid phase block into the cavity of cylindrical mold 2 (26 mm in diameter), fill with 12 g of liquid phase source powder, and press it into liquid phase source coated Y 2 BaCuO 5 S...

Embodiment 2

[0040] In step (3) of pressing the precursor block, take 6g of Y 2 BaCuO 5 The precursor powder is put into a cylindrical mold 1 (diameter 16 mm) and pressed into Y 2 BaCuO 5 solid phase block; the Y 2 BaCuO 5 Put the solid phase block into the cavity of cylindrical mold 2 (20 mm in diameter), fill with 10.5 g of liquid phase source powder, and press it into liquid phase source coated Y 2 BaCuO 5 Sample block; i.e. Y 2 BaCuO 5 The mass ratio of the precursor powder to the filled liquid phase source powder is 1:1.75, and the diameter of the cylindrical mold 2 is 4 mm larger than that of the cylindrical mold 1; then take 2g Yb 2 o 3 The initial powder was put into a cylindrical mold 2 (20 mm in diameter) and pressed into a thin sheet with a thickness of about 2 mm as a support block.

[0041] In step (5) of the infiltration growth monodomain yttrium barium copper oxide bulk material, the assembled precursor block is placed on the Al 2 o 3 On the gasket, 3 MgO single c...

Embodiment 3

[0044] In step (3) of pressing the precursor block, take 6g of Y 2 BaCuO 5 The precursor powder is put into a cylindrical mold 1 (diameter 16 mm) and pressed into Y 2 BaCuO 5 solid phase block; the Y 2 BaCuO 5 Put the solid phase block into the cavity of cylindrical mold 2 (30 mm in diameter), fill with 13.5 g of liquid phase source powder, and press it into liquid phase source coated Y 2 BaCuO 5 Sample block; i.e. Y 2 BaCuO 5 The mass ratio of the precursor powder to the filled liquid phase source powder is 1:2.25, and the diameter of the cylindrical mold 2 is 14 mm larger than that of the cylindrical mold 1; then take 3.5g Yb 2 o 3 The initial powder was put into a cylindrical mold 2 (30 mm in diameter) and pressed into a thin sheet with a thickness of about 2 mm as a support block.

[0045] In step (5) of the infiltration growth monodomain yttrium barium copper oxide bulk material, the assembled precursor block is placed on the Al 2 o 3 On the gasket, 5 MgO singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com