Preparation method of single-domain Gd-Ba-Cu-O superconducting block

A technology of gadolinium barium copper oxide and superconducting block, which is applied in the field of high-temperature copper oxide superconducting materials, can solve the problems of increased cost, prolonged preparation period of infiltration growth method, and low carbon content, so as to improve utilization rate and shorten experiment Period, effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Preparation of Gd 2 BaCuO 5 Pioneer Powder

[0033] Take 85.0421g Gd 2 O 3 , 46.2957g BaCO 3 , 18.6622g CuO powder mixed, namely Gd 2 O 3 with BaCO 3 , The molar ratio of CuO powder is 1:1:1, and Gd is made by solid-state reaction method. 2 BaCuO 5 pink. Take 100g Gd 2 BaCuO 5 Add powder to ball mill, add Gd 2 BaCuO 5 Powder mass 2% CeO 2 powder, mixed well, prepared as Gd 2 BaCuO 5 Pioneer Powder.

[0034] 2. Preparation of liquid source powder

[0035] Take 106.9053g BaCO 3 , 43.0947g CuO mixed, namely BaCO 3 The molar ratio to CuO powder is 1:1, and BaCuO is made by solid-state reaction method 2 pink. 11.64g Y 2 O 3 Initial powder, 120g BaCuO 2 Powder and 24.6g CuO powder are mixed evenly in the ball mill, namely Y 2 O 3 Initial powder and BaCuO 2 The molar ratio of powder and CuO powder is 1:10:6, which is used as the liquid source powder.

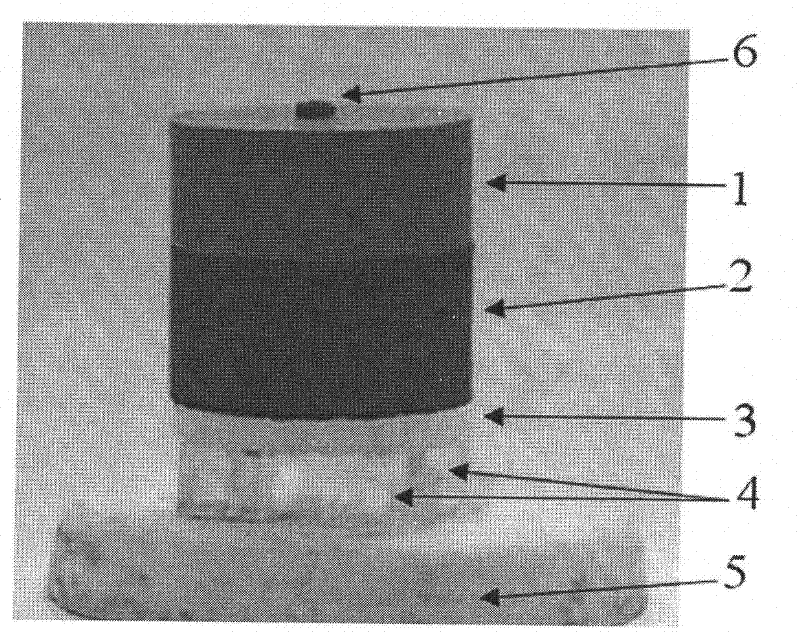

[0036] 3. Suppress Gd 2 BaCuO 5 Pioneer block and liquid phase block

[0037] Take 11g liqui...

Embodiment 2

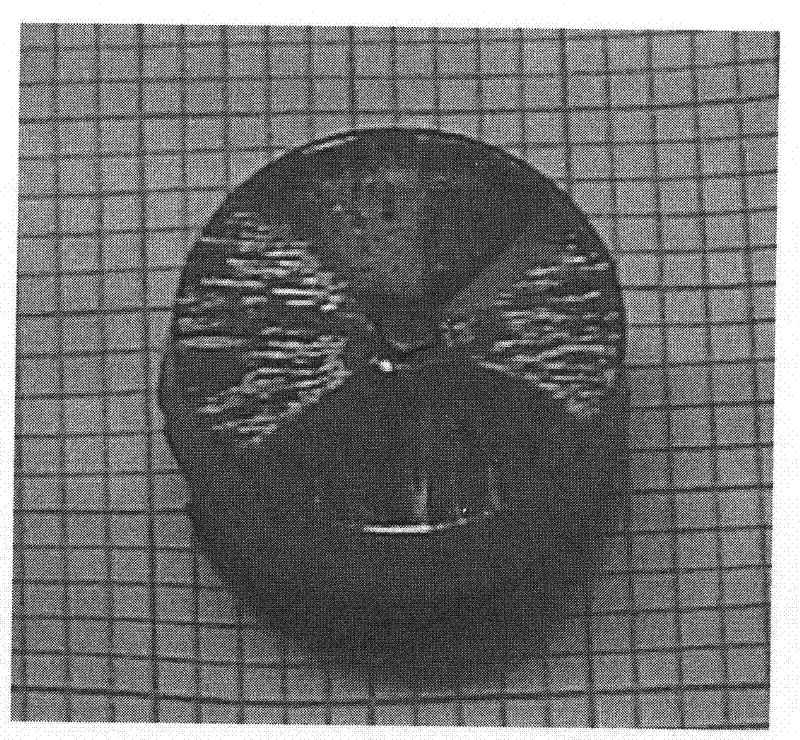

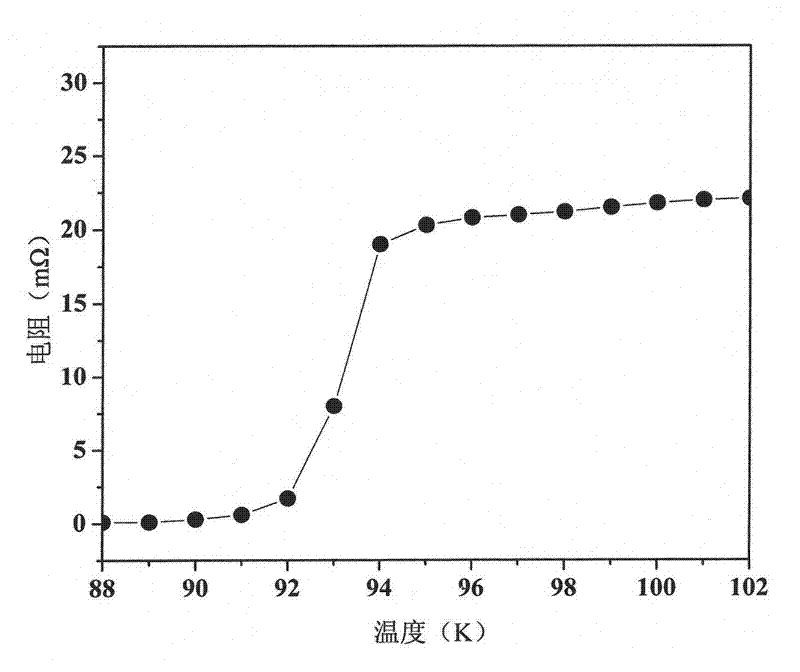

[0051] in preparation of Gd 2 BaCuO 5 In step 1 of the precursor powder, the preparation of Gd 2 BaCuO 5 The raw materials used in the powder and the preparation method are the same as in Example 1, take 100g Gd 2 BaCuO 5 Add powder to ball mill, add Gd 2 BaCuO 5 Powder mass 1% CeO 2 powder, mixed well, prepared as Gd 2 BaCuO 5 Pioneer Powder. The other steps of this embodiment are the same as those of Embodiment 1. A gadolinium-barium-copper-oxygen superconducting block with a diameter of 20 mm was prepared, and the prepared single-domain gadolinium-barium-copper-oxygen superconducting block was tested for the magnetic levitation force by using a three-dimensional magnetic field and a magnetic force test device, and the magnetic levitation force density reached 8.9N / cm 2 .

Embodiment 3

[0053] suppressing Gd 2 BaCuO 5 Pioneer block and liquid phase block In step 3, take 30g Gd 2 BaCuO 5 Pioneer powder and 30g liquid phase source powder, respectively pressed into Gd with a diameter of 30mm 2 BaCuO 5 Pioneer block and liquid phase block. In pressing the support block step 4, take 4.5g Yb 2 O 3 The powder is pressed into a compact with a diameter of 30mm and a thickness of 2mm as a support block. In the step 6 of growing the single-domain gadolinium barium copper oxide block by infiltration, the assembled precursor block is put into the tube furnace, and the temperature is raised to 800 ℃ at a heating rate of 100 ℃ per hour, and the temperature is kept for 20 hours. The heating rate of 50°C was raised to 1055°C, and the temperature was kept for 1.5 hours; the temperature was lowered to 1035°C at a cooling rate of 60°C per hour, slowly cooled to 1015°C at a cooling rate of 0.2°C per hour, and cooled to room temperature naturally with the furnace to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com