A mine-used arc-shaped anti-scouring closed wall and its construction method

A construction method and airtight wall technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as insufficient strength to resist air waves, threats to mine safety production, and economic losses in coal mines, so as to ensure the airtight effect and strength Requirements, ensure the compactness of concrete, and reduce the effect of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

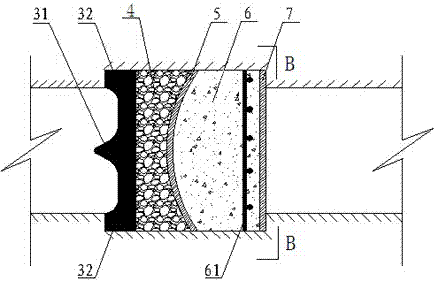

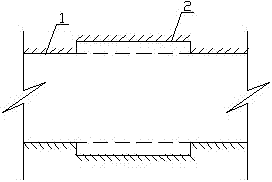

[0049] According to the accompanying drawings, a kind of arc-shaped anti-scouring airtight wall for mines is firstly slotted at the position where the roadway needs to be sealed before making the present invention. The grooves are continuously distributed along the left and right side of the roadway, the top plate, and the bottom plate, and the depth of the cut is 500 mm. The width is 500-800 mm. According to the incoming direction of air waves, from the inside to the outside, there are diversion layer (3), filling layer (4), curved steel plate layer (5), concrete airtight wall (6), and flat steel plate layer (7). The layers all reach the left and right lane sides, roof and floor cut boundaries (2). An annular diversion arc (33) is arranged around the windward surface of the diversion layer (3), and a central protrusion (34) is arranged in the center, and the diversion arc (33) and the central protrusion (34) form a ring-mounted groove (35), the ring dress groove (35) ring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com