LED (light-emitting diode) lamp forming process

A molding process and LED lamp technology, applied in the field of LED lighting, can solve problems such as complex manufacturing process and environmental pollution, and achieve the effect of easy bending and forming, convenient bending, and improved appearance and display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

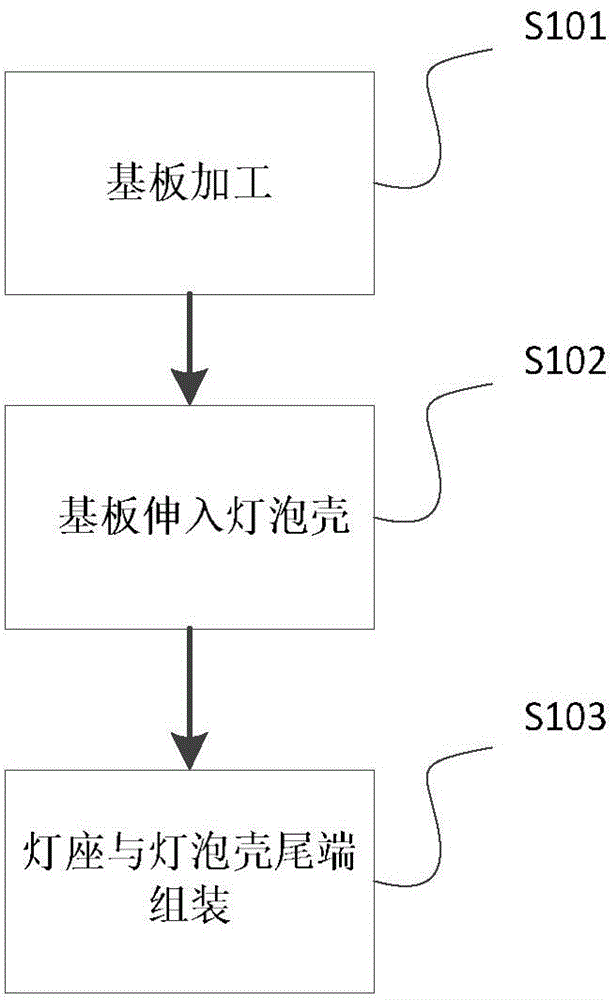

[0045] Combine figure 1 In the illustrated embodiment, those skilled in the art understand that the process flow for assembling the LED lamp provided by the present invention is preferably achieved through the following steps:

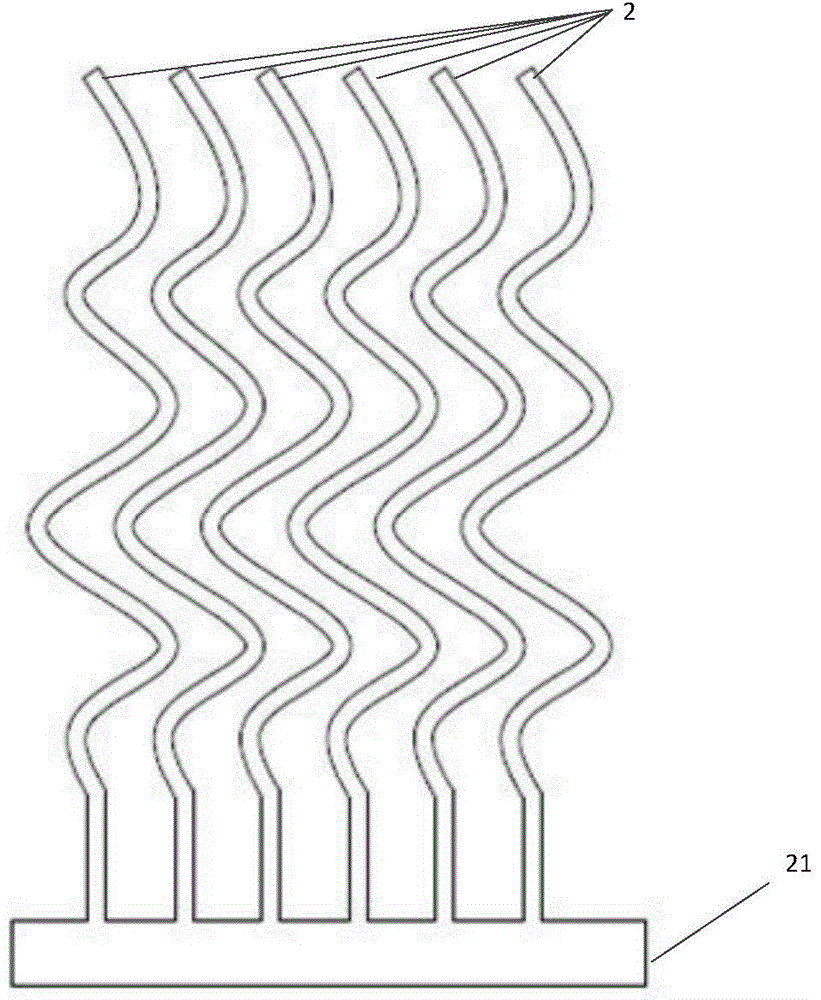

[0046] First, perform step i. Process the substrate 2 to adapt it to the shape of the bulb shell (1) of the LED lamp. Those skilled in the art understand that the LED lamp provided by the present invention includes a substrate 2 and an LED bulb shell 1. The substrate 2 is attached to the LED bulb shell 1, specifically as described in step ii below. Therefore, the substrate 2 needs to be processed so that its shape is compatible with the LED bulb shell 1. For example, preferably, the LED bulb shell 1 is in the shape of a gourd, that is, the middle part of the LED bulb shell 1 is thick, and the tail part and the front part are relatively smoothly transitioned and reduced. At this time, the substrate 2 is attached to the When inside the LED bulb shell 1, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com