Super large torque standard machine weight loading system

A loading system and super-large technology, applied in the direction of force/torque/work measuring instrument calibration/testing, measuring devices, instruments, etc., can solve the problem of large weights, achieve stable weight loading, and meet the requirements of weight loading. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

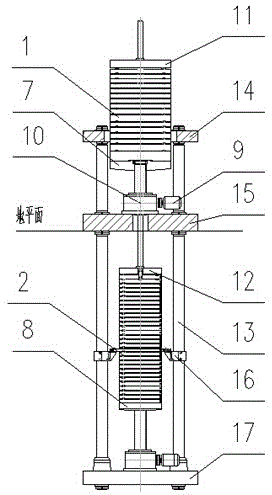

[0018] Such as figure 1 As shown, a super large torque standard machine weight loading system includes: weight parts, weight trays, hanging parts, bracket parts, electric control system 9 and lifting mechanism 10.

[0019] Wherein, the weight components are divided into upper and lower layers, that is, the upper layer weight group 1 and the lower layer weight group 2 . Each layer of weight group is composed of several round cake weights with different diameters. The centers of all weights on the upper and lower floors are on the same vertical straight line.

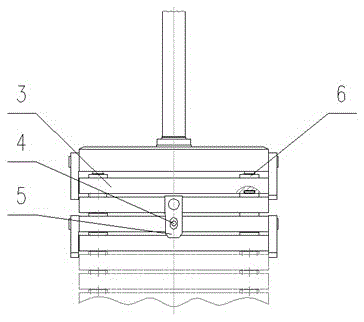

[0020] Such as figure 2 As shown, each weight group is composed of a number of round cake weights with different diameters, and each weight is composed of a weight block 3, three pin shafts 4, three lifting lugs 5, and three cone guides. Composed of 6 positioning pins, the weight block 3 is a circular structure, with a conical guiding positioning groove at the bottom; the pin shaft 4 is evenly distributed on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com