Method for testing destructive effect and performance impact of alkali metal and zinc vapor to coke

A destructive, metal vapor technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, weighing by removing certain components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

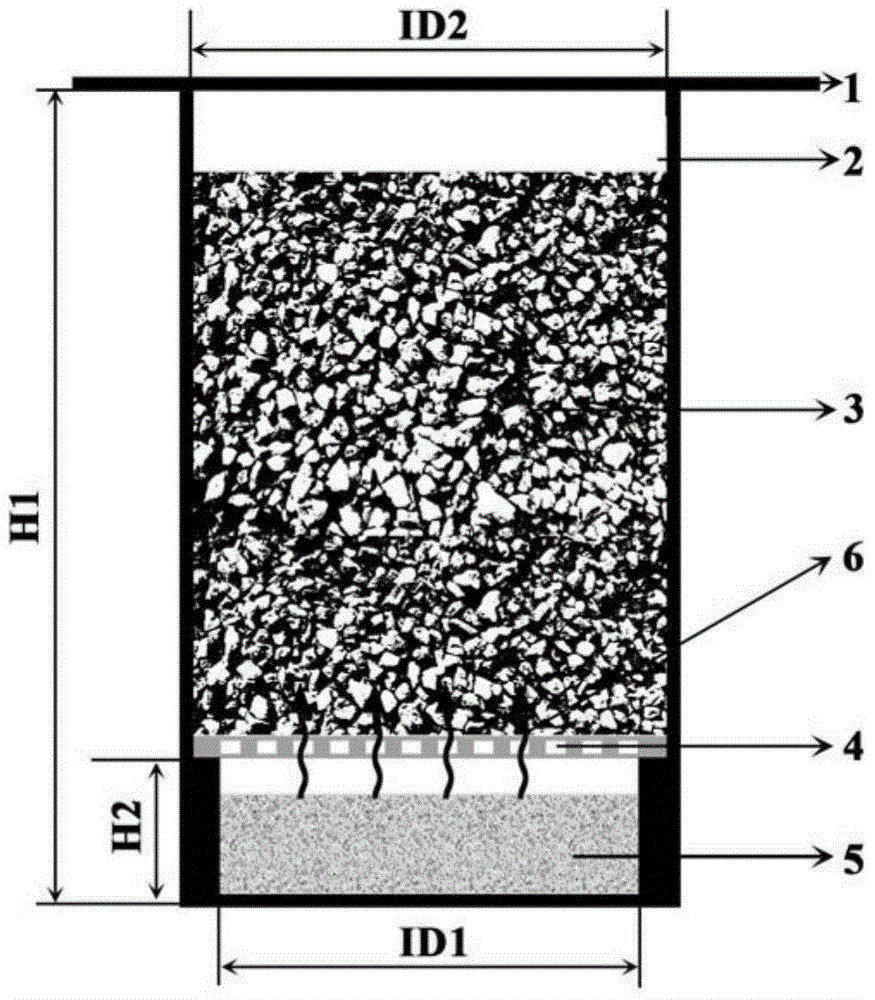

[0029] The technical solution of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments.

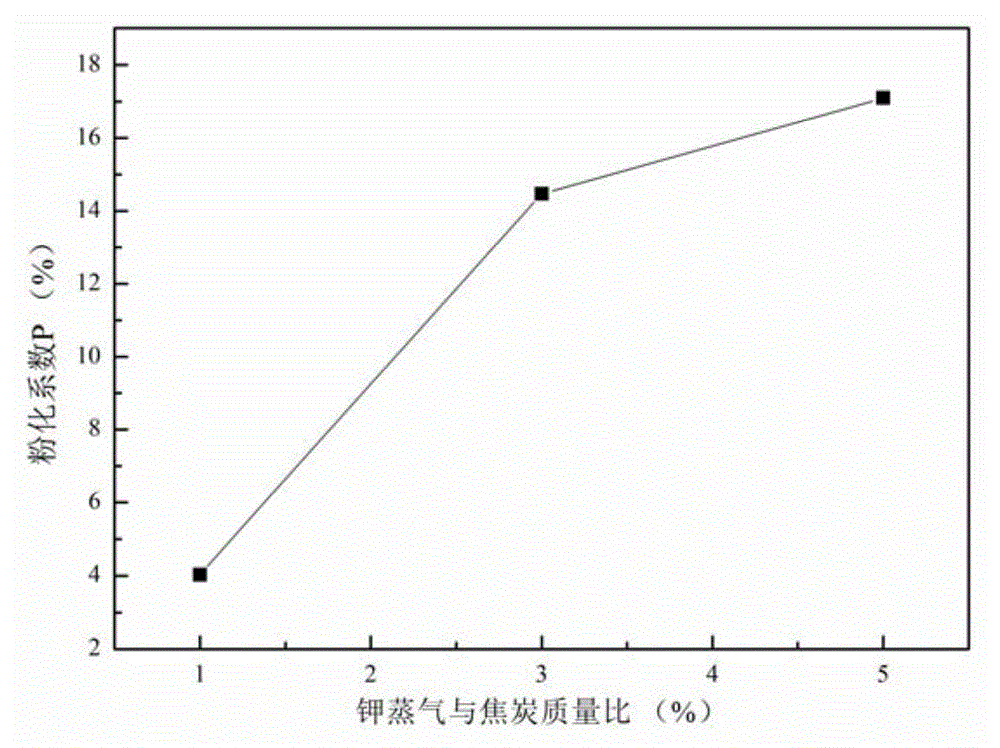

[0030] Taking the direct destruction of coke by potassium vapor at high temperature and its performance impact as an example, the specific implementation method includes the following process:

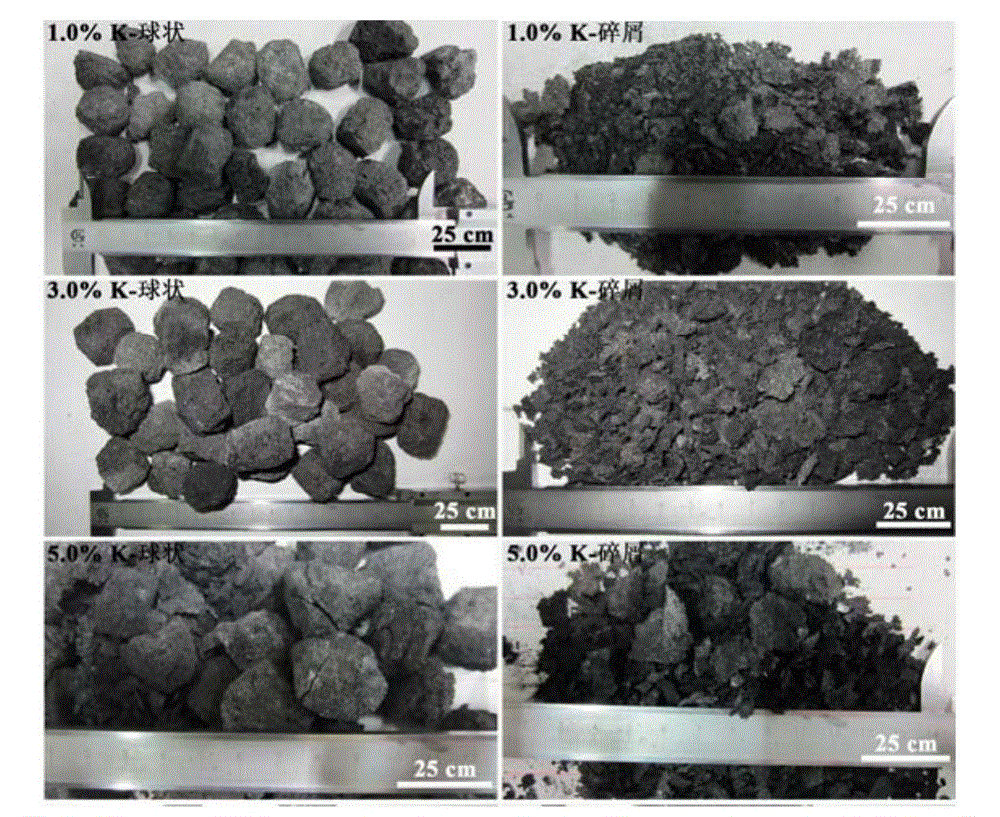

[0031] (1) Take the coke actually used in the blast furnace, crush it with a jaw crusher, and then rest it into coke pellets of 23-25 mm, and weigh three parts of 300 g ± 0.5 g as the experimental sample.

[0032] (2) According to the reaction K 2 CO 3 +2C=3CO+2K calculates the mass ratio of potassium carbonate powder and activated carbon powder, and the actual amount of activated carbon powder used is 1.5 times the theoretical reduction requirement, and finally the ratio of potassium carbonate powder to activated carbon powder is 3.8333:1. Amount of potassium carbonate powder and activated carbon powder, mixed according to 3.8333:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com