Road finishing machine

A road finishing machine and path technology, applied in road repair, road, road, etc., can solve the problems of low construction and maintenance costs, and achieve the effects of reducing maintenance costs, avoiding deposition, and increasing flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

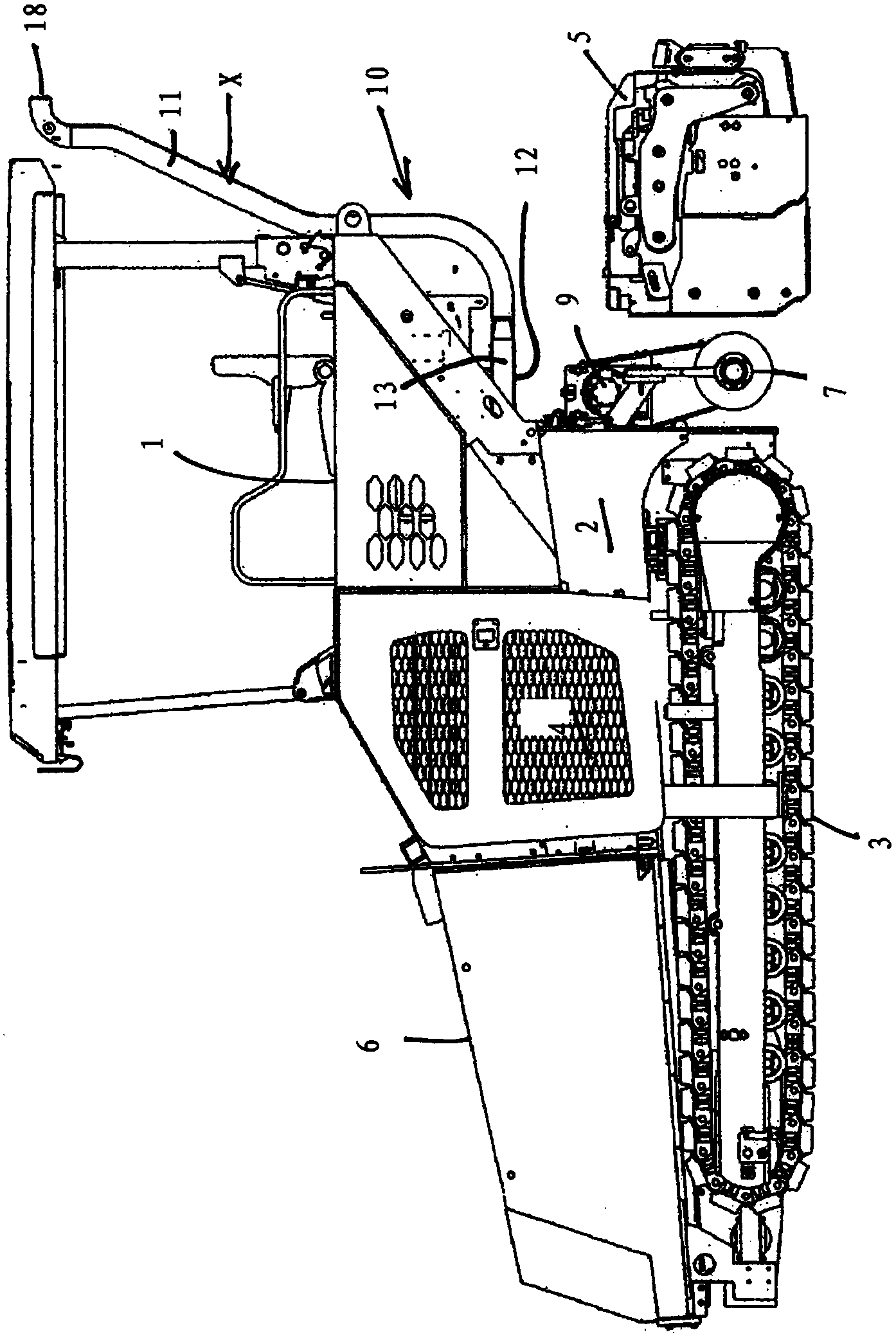

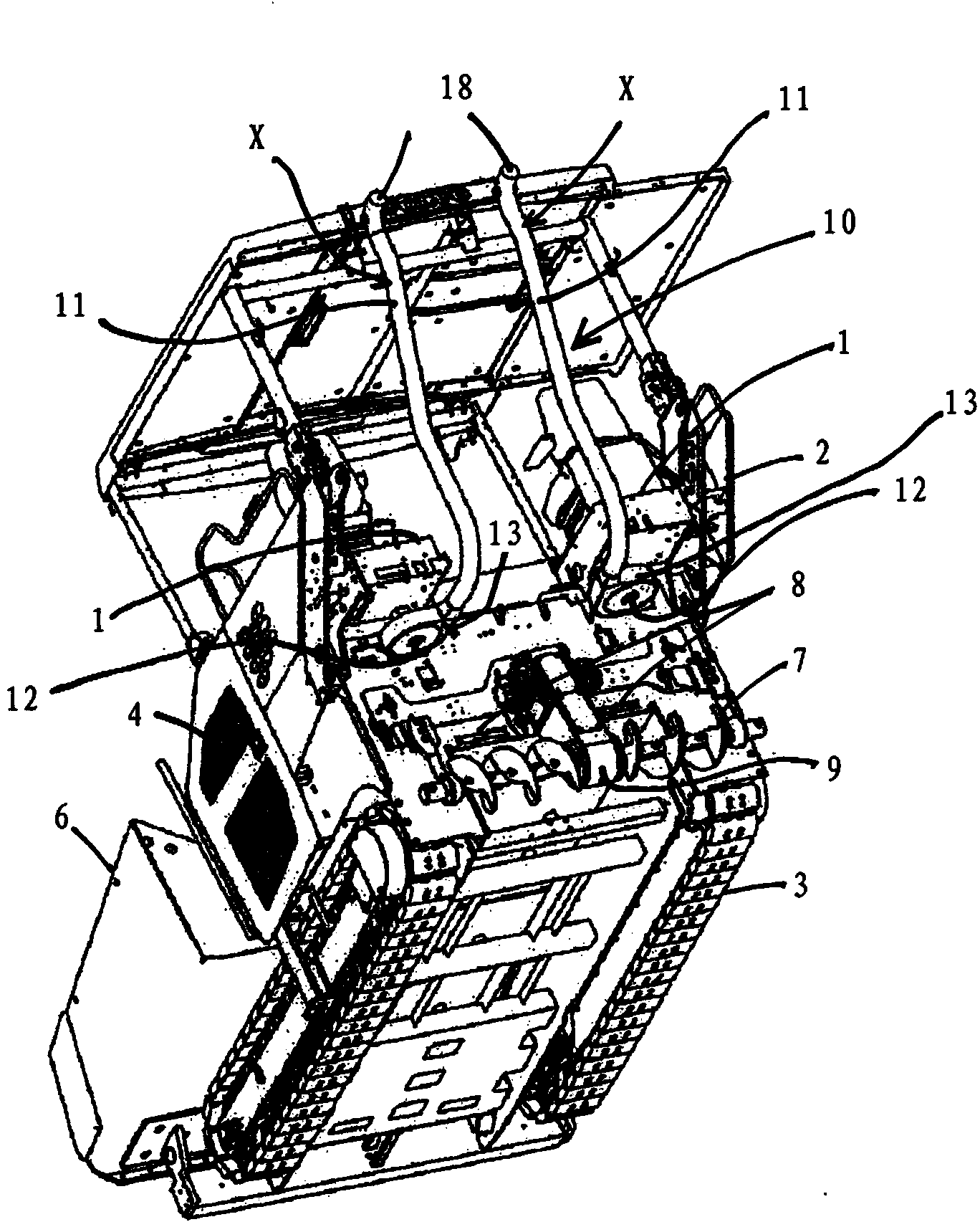

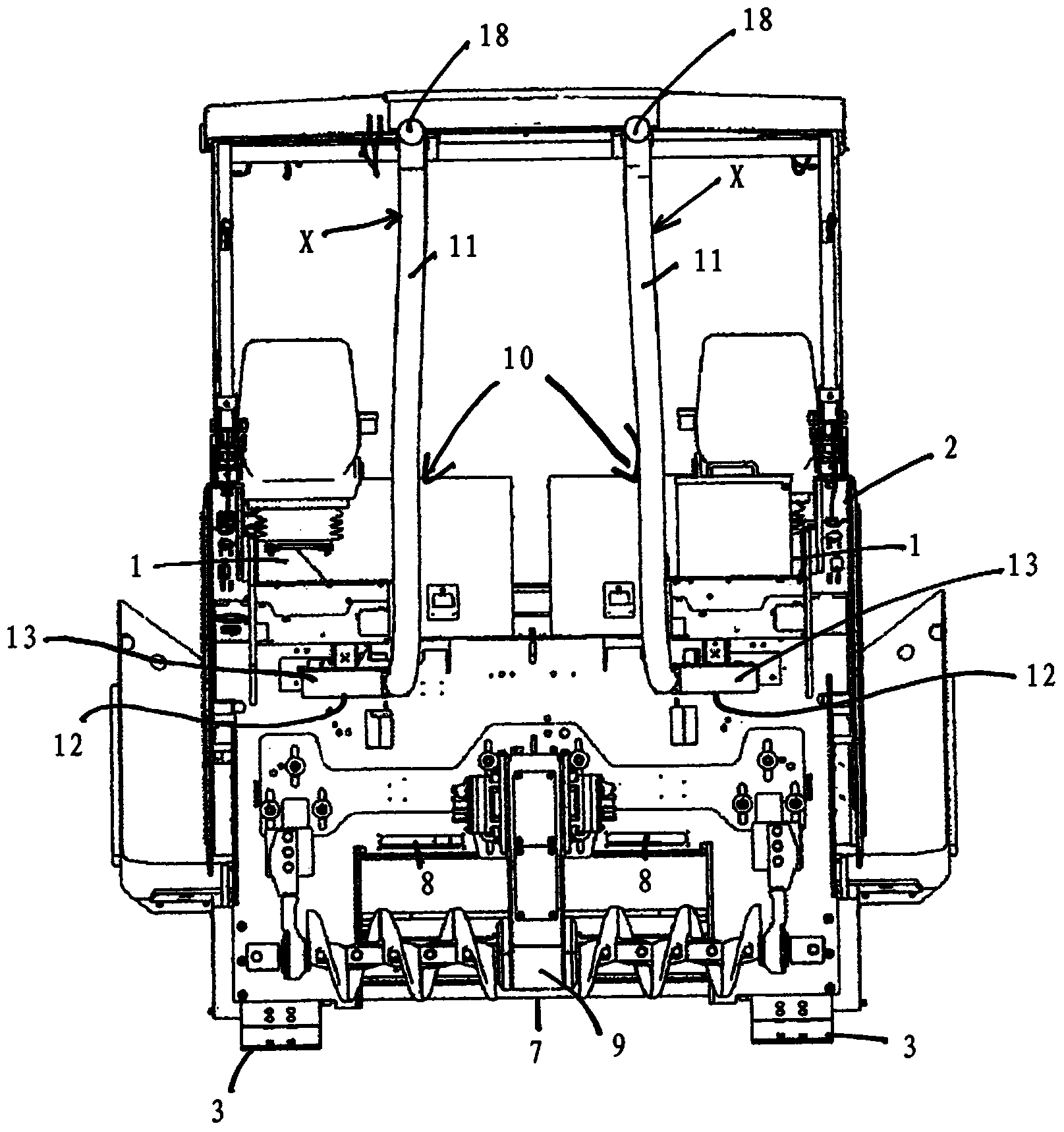

[0028] Figure 1 to Figure 3 Shown is a road finishing machine with a chassis 2 supporting a driver's platform 1, a running gear 3, at least one drive unit 4, a hydraulic system, a beam 5, an asphalt supply device comprising a storage hopper 6 and a secondary storage hopper 6 Longitudinal conveying device 8 for conveying to transverse distributor 7. This is a conventional configuration for road finishing machines. The running gear 3 is generally a crawler-type running gear, but it can also be a tire-type running gear or other running gears. The longitudinal conveying device 8 preferably comprises two conveyor belts running parallel in order to be able to feed the left and right parts of the transverse distributor separately. The transverse distributor 7 is preferably designed as a distributor screw with a preferably centrally arranged screw drive 9 .

[0029] The road finishing machine also comprises a steam extraction device 10 operated as a blower, which has at least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com