Material grabbing hook type feeding mechanism

A technology of feeding mechanism and material hook, applied in metal processing equipment, feeding device, manufacturing tool, etc., can solve the problem of inconvenient to grab parts and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

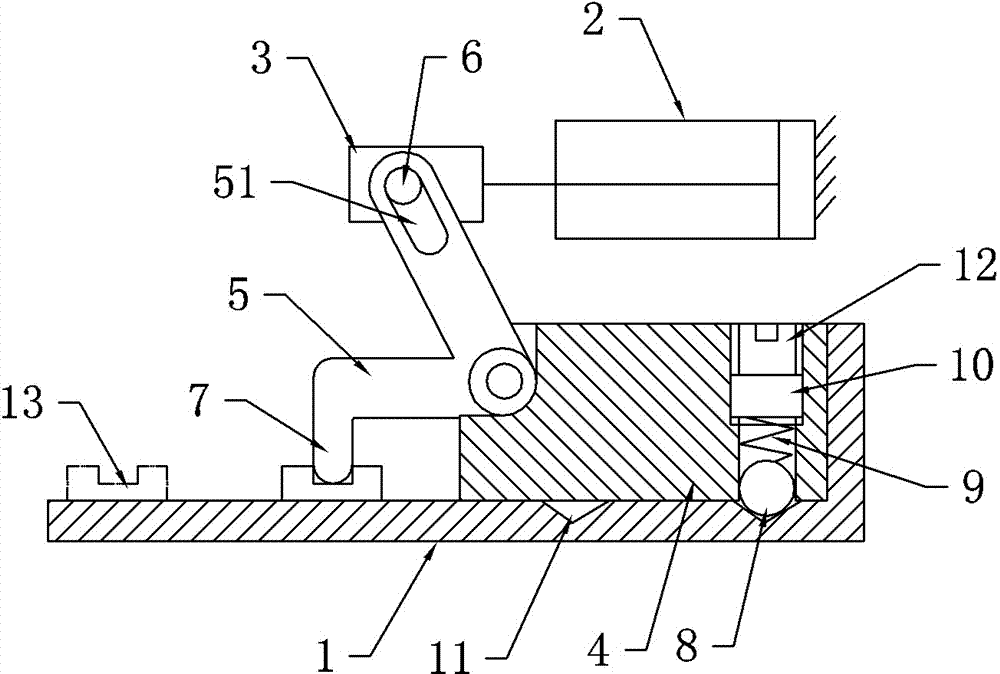

[0012] like figure 1 As shown, a material grabbing hook type feeding mechanism includes a cylinder 2, a machine base 1, a slider 4 and a swing rod 5, the slider 4 is slidingly matched with the machine base 1, wherein the swing rod 5 is in an "L" shape, and One end is provided with a catch hook 7 towards the outside of the swing rod 5, the other end of the swing rod 5 is provided with a strip hole 51, the piston rod of the cylinder 2 is provided with a connecting piece 3, and the connecting piece 3 is provided with a pin matching the strip hole 51 6. The corner of the pendulum 5 is hinged with the slider 4; the slider 4 is provided with a positioning structure, the positioning structure includes a compression spring 9 and a ball 8 connected to one end of the compression spring 9, the ball 8 protrudes from the bottom of the slider 4 and Contrasted with the machine base 1 , the machine base 1 is provided with two positioning grooves 11 arranged along the feeding direction and mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com