Ram sealing tool

A technology of ram and tooling is applied in the field of tooling for large-scale CNC machine tool closed headstock and ram mutual grinding and processing, which can solve the problems of low production efficiency, easy damage to workpieces, poor scraping and grinding accuracy, etc., and achieve high production efficiency. , The inclination angle is convenient to ensure the effect of scraping and grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

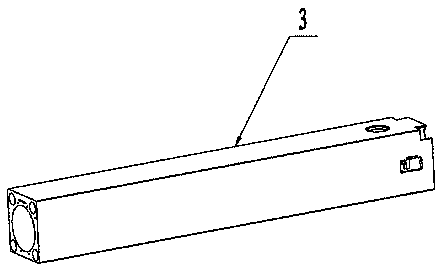

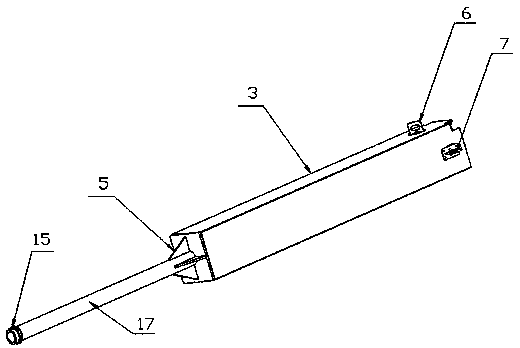

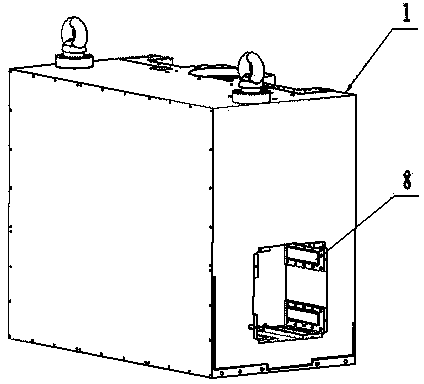

[0026] like Figure 1 to Figure 9 The ram co-research tooling shown mainly includes crane 10, headstock 1, headstock V-shaped support 2, ram 3, ram V-shaped support 4, support tube 11, square hole guide rail of headstock 1 The inner side of the surface is provided with a ram insert 8, and a detachable hook is provided on the ram 3, and the detachable hook includes a long tube hook 5, a square bottom hook 6 and a round bottom hook 7, and the long tube hook 5 is installed in such as figure 2 On one end face of the shown ram 3, the round bottom hook 7 and the square bottom hook 6 are installed on such as figure 2 On the two adjacent surfaces of the other end of the ram 3 shown, the long pipe hook 5 is composed of a bottom plate and a long pipe 18. A plurality of rings 15 are fixed on the pipe surface of one end of the long pipe 17, and the other end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com