Halftone fixing device of printing machine

A fixing device and printing machine technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of low scraping quality, lower repeatability, and poor fixing effect, so as to ensure scraping accuracy, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

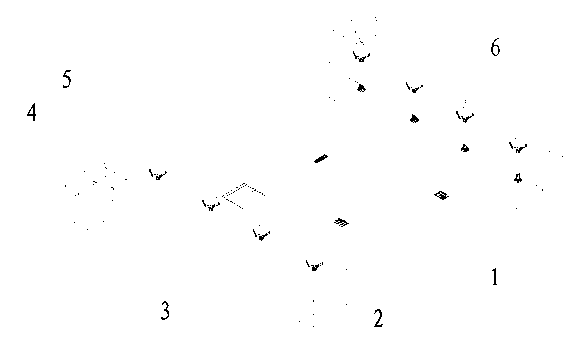

[0011] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0012] Referring to the accompanying drawings, the screen fixing device of the printing machine includes a guide rail 4 fixedly installed on the printing machine body, the guide rail 4 is provided with a sliding block 3 slidingly connected with it, and the inner side of the sliding block 3 is provided with a fixing groove 2 for fixing A screen plate 1 is installed in the groove 2, and a fastening wrench 5 is installed on the upper part of one end connected to the slide block 3 and the guide rail 4.

[0013] The fixing screws 6 fix the screen plate 1 in the fixing groove 2 .

[0014] After such installation, adjust the distance between the two sliding blocks 3 according to the length of the screen plate 1, so that the distance between the two fixing grooves 2 is suitable for the length of the screen plate 1. After the adjustment, tighten the tightening w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com