Fuel tank end cover welding machine

A welding machine and fuel tank technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as high maintenance and production costs, large investment in welding of fuel tank end caps, equipment interchangeability, and poor welding quality. , to achieve good welding quality, saving labor costs, and good welding process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

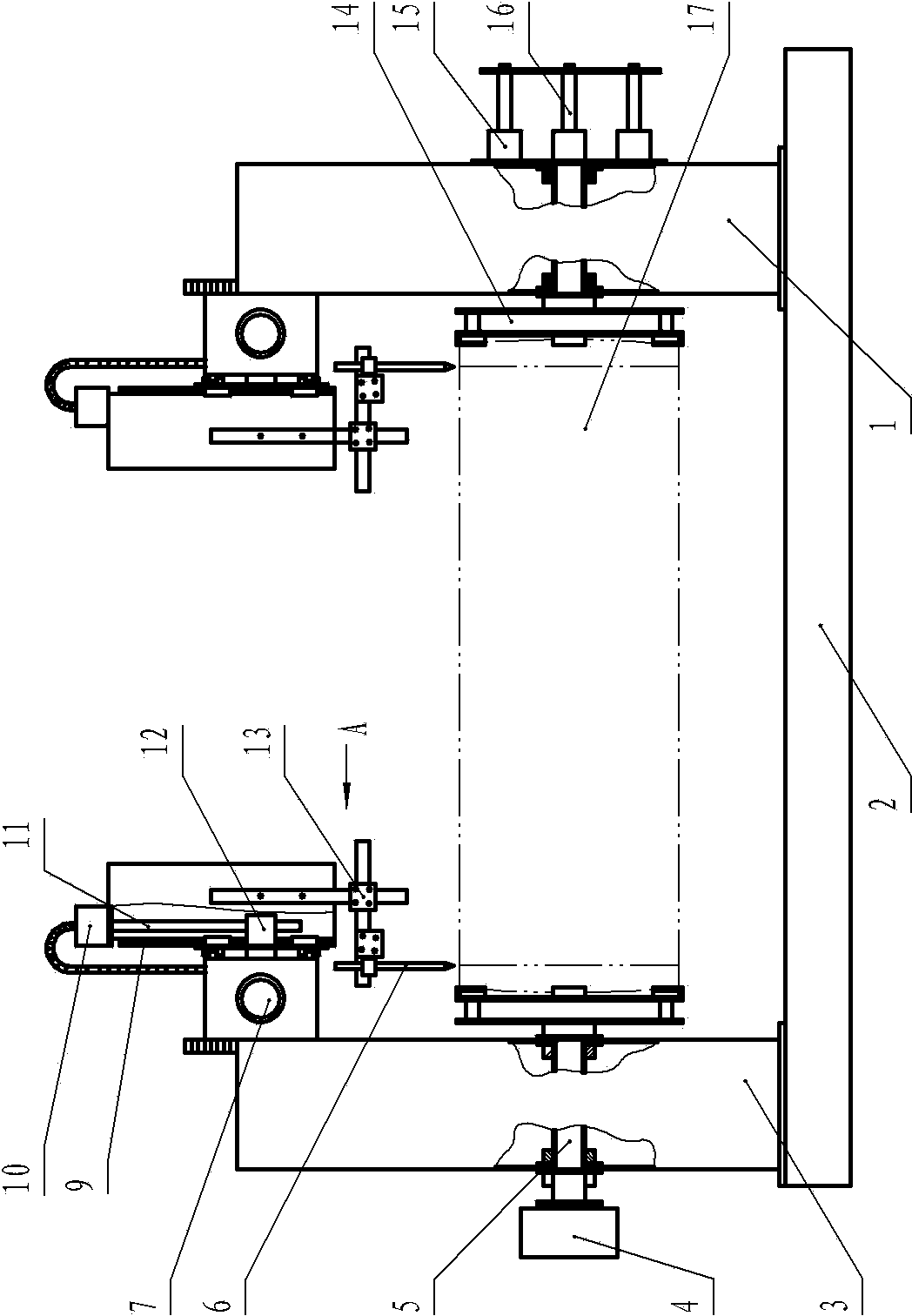

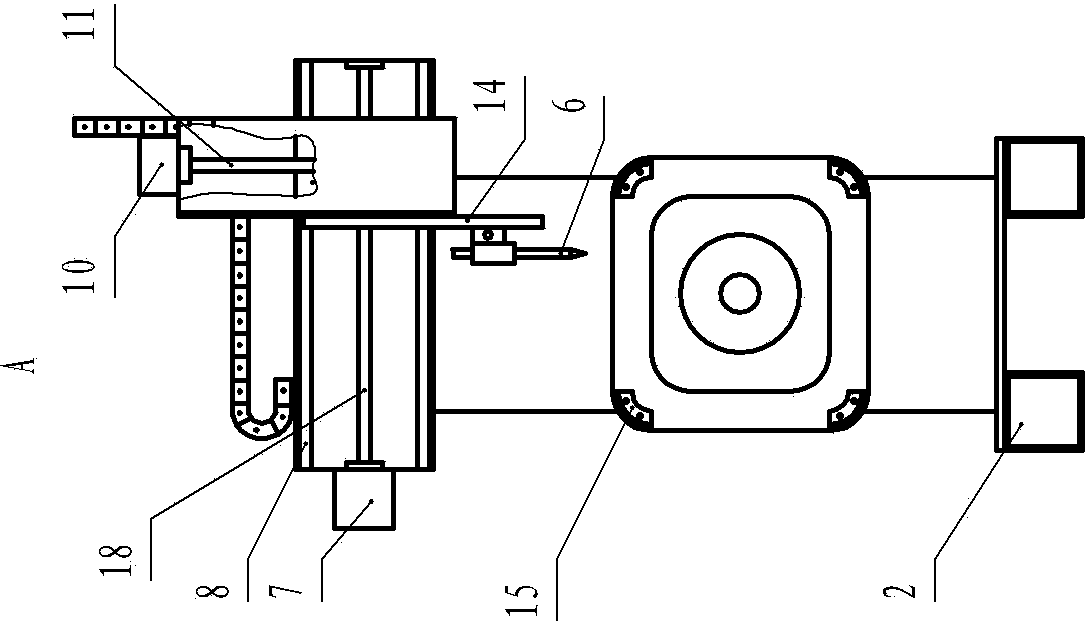

[0015] figure 1 with figure 2 The shown fuel tank end cap welding machine includes a base 2, on which a left frame 3 and a right frame 1 are respectively arranged on the left and right sides of the base 2; between the lower part of the left frame 3 and the lower part of the right frame 1 The clamping device 14 that is used to clamp workpiece to be welded is arranged, and the workpiece to be welded in this embodiment is fuel tank 17; The main shaft stepping motor 4 on the left frame 3 is driven; the other end of the clamping device 14 is connected with the clamping shaft 16 installed on the right frame 3, and the clamping shaft 16 is connected by two clamps mounted on the right frame. Cylinder 15 is driven to move left and right, and the fuel tank 17 to be welded is clamped. The left frame 3 above the clamping device 14 and the inside of the right frame 1 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com