Deburring positioning tool for end face of automobile gear-shifting shifting fork

A technology for gear shifting and positioning tooling for automobiles, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as unsatisfactory deburring effects, uneven end faces, low work efficiency, etc., and achieve novel ideas and automation High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

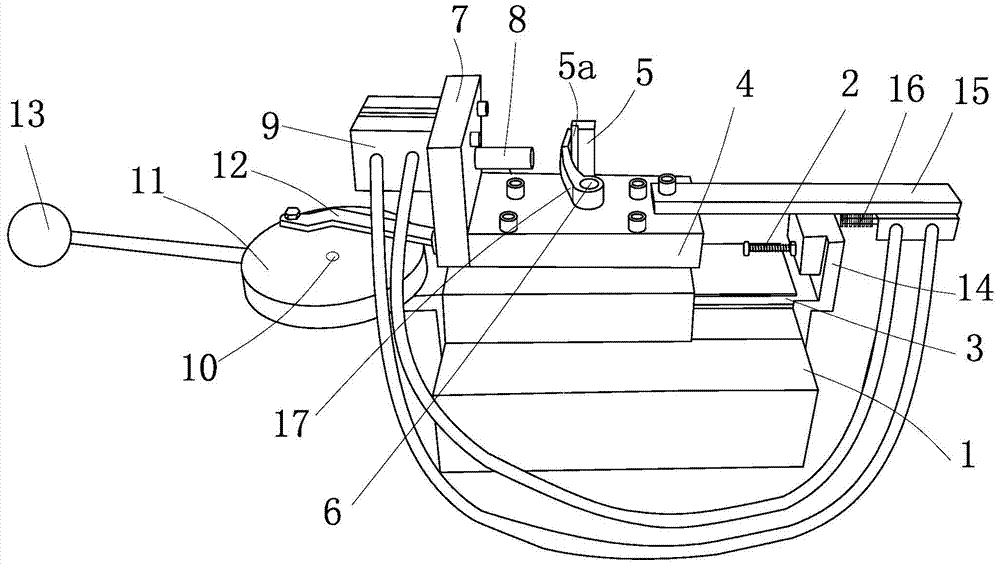

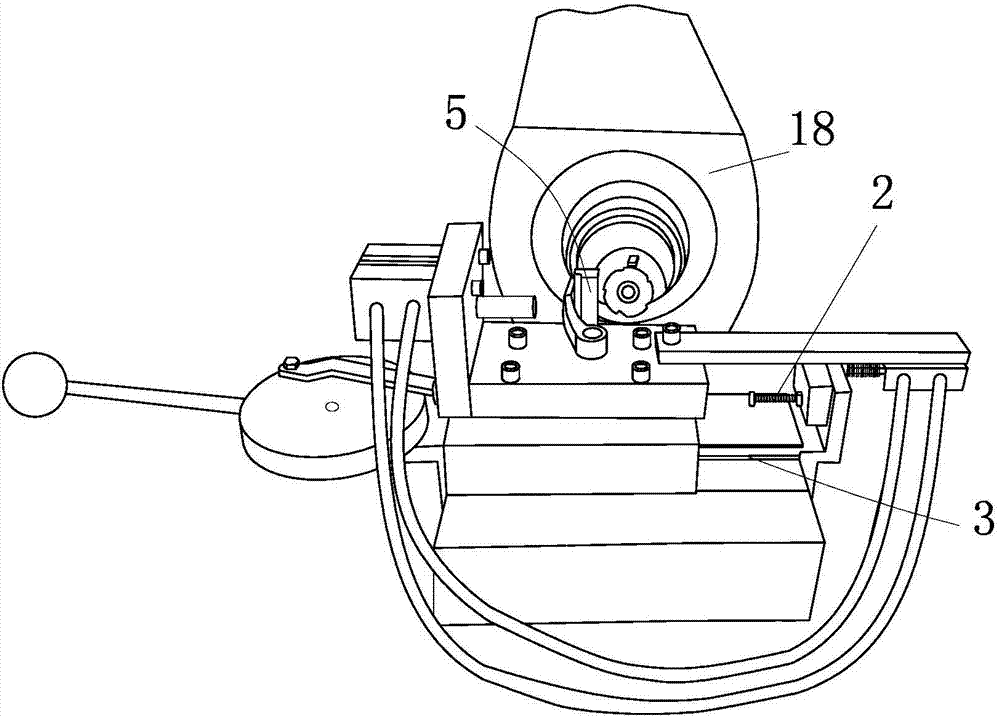

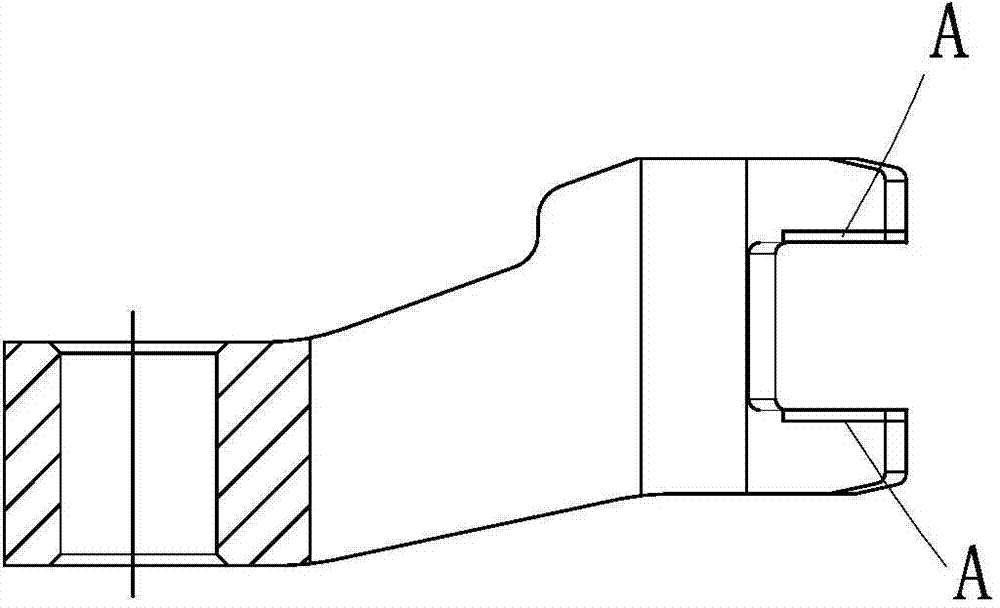

[0015] Such as figure 1 As shown, a deburring and positioning tool for the end face of an automobile shift fork is composed of a workbench 1, a horizontal limit screw 2, a guide rail 3, a slide seat 4, an end face positioning column 5, a workpiece set cylinder 6, a first vertical plate 7, Pneumatic ejector rod 8, cylinder 9, shaft 10, disc 11, connecting rod 12, handle 13, second vertical plate 14, horizontal connecting plate 15, pneumatic switch 16 and so on.

[0016] The guide rail 3 is installed above the workbench 1, the guide rail 3 extends left and right, the slide seat 4 matches the guide rail 3, and the slide seat 4 can move left and right along the guide rail 3. Preferably, the sliding seat 4 is connected with the guide rail 3 through a dovetail groove.

[0017] The sliding seat 4 is fixedly provided with an end face positioning column 5, a wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com