Rotary indexing device for machining center tool magazine

An indexing device and machining center technology, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of machining center spindle collision, tool position deviation, and knife jamming faults, etc., to improve production efficiency, The effect of increasing the service life and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structural features of the cooling device of the drawing die of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to clearly demonstrate the technical innovation effect of the present invention.

[0019] The invention aims at proposing a rotary indexing device for a tool magazine of a machining center to solve the accuracy of tool holder rotary index switching.

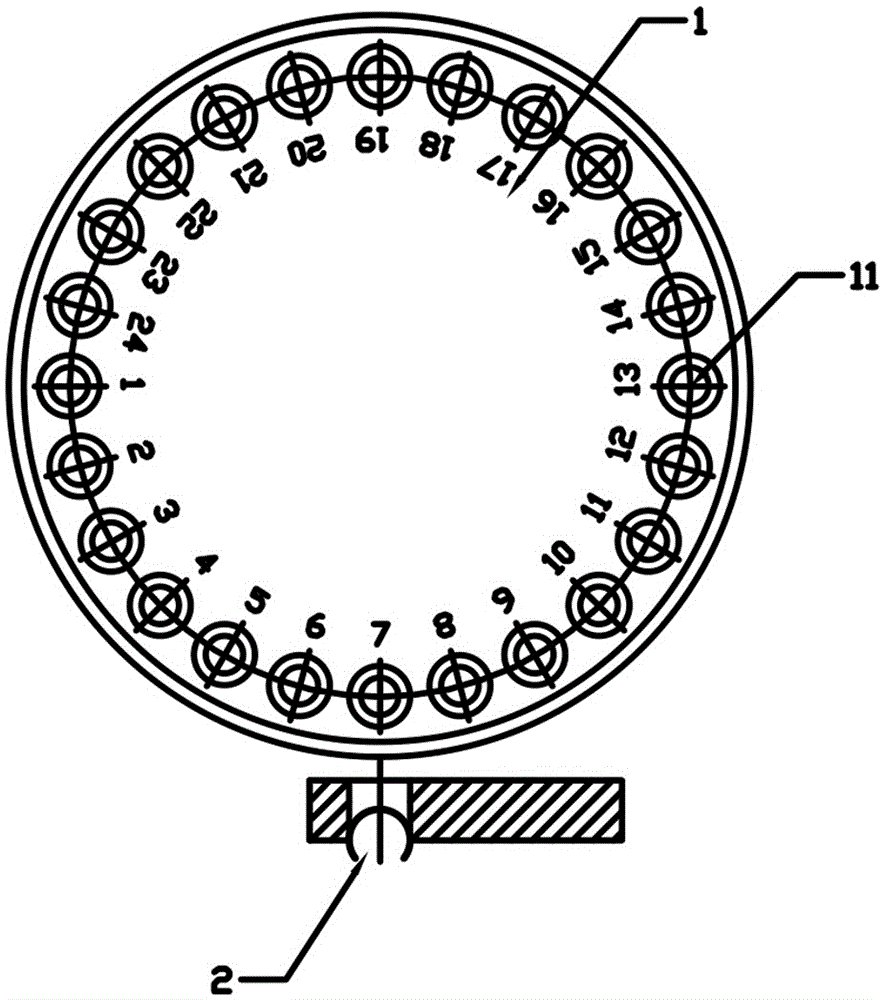

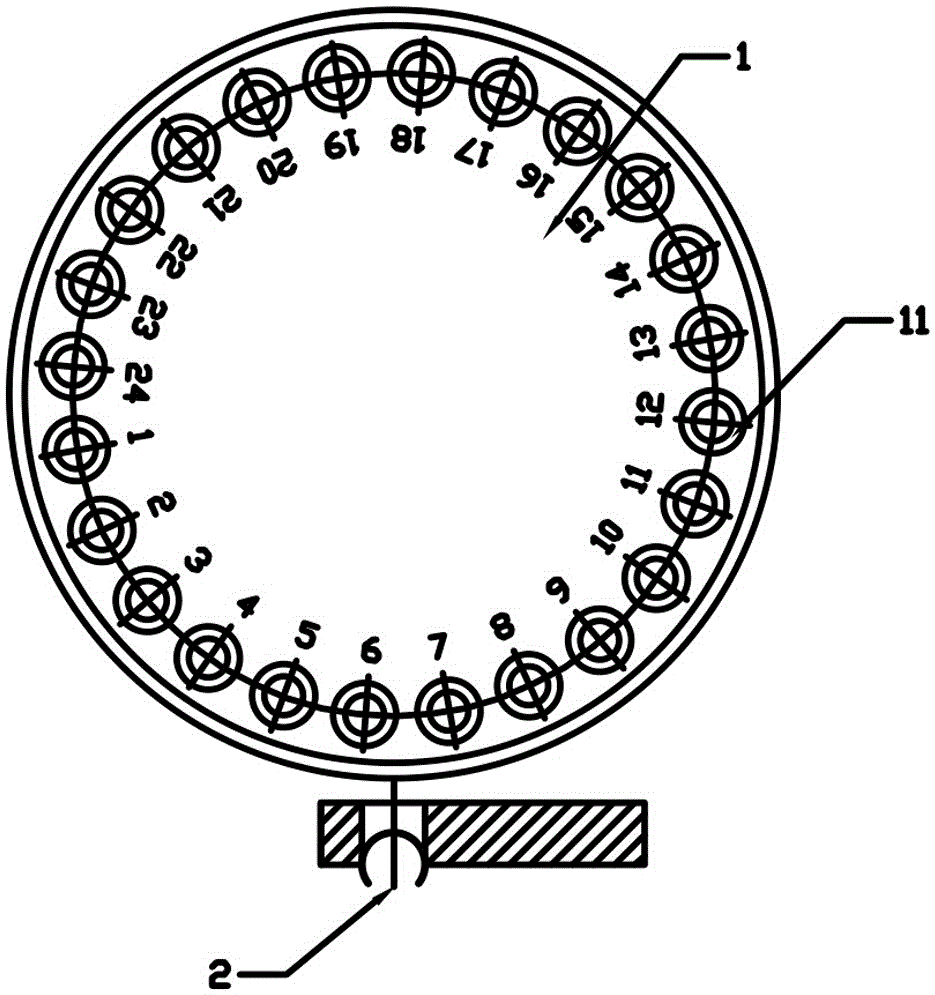

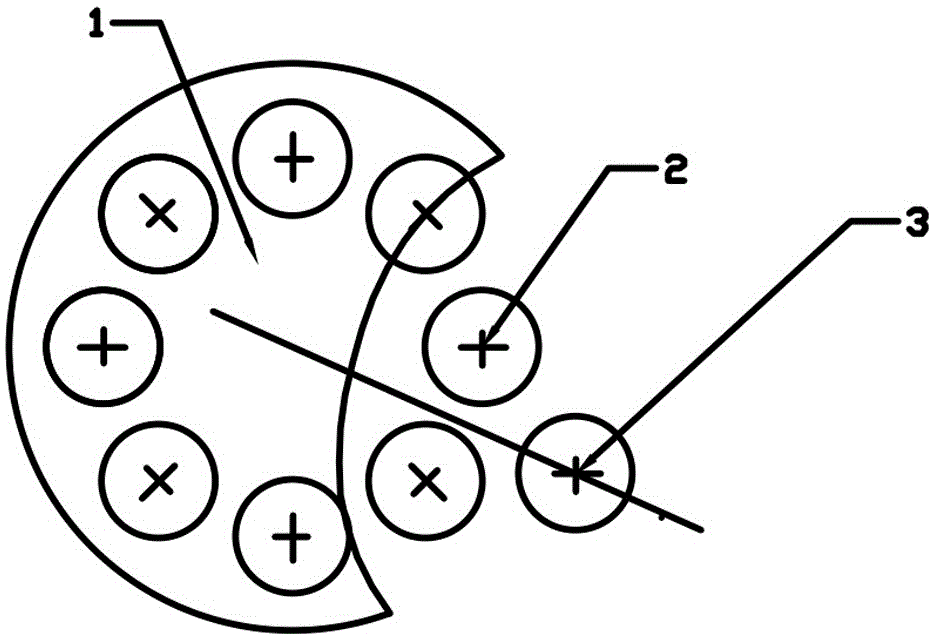

[0020] From the perspective of the traditional machining center device, the tool magazine is equipped with a cutterhead, a numerical control unit and a cutterhead counting sensor, the cutterhead is mechanically connected to the motor shaft, the cutterhead counting sensor is connected to the numerical control unit, and the output of the numerical control unit is connected to control the rotation of the toolholder motor (not shown). However, this creation improves the tool magazine. The tool magazine of the machining center is equipped with a rotary i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap