Gas drainage method by pressure relief of coal bed bottom plate through ground drilling and loosening blasting

A technology of loose blasting and coal seam floor, which is applied in the direction of gas discharge, earth drilling, mining fluid, etc. It can solve the problems of high labor intensity, long time consumption, gas gushing, etc., and achieve simplified gas drainage process and light labor , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

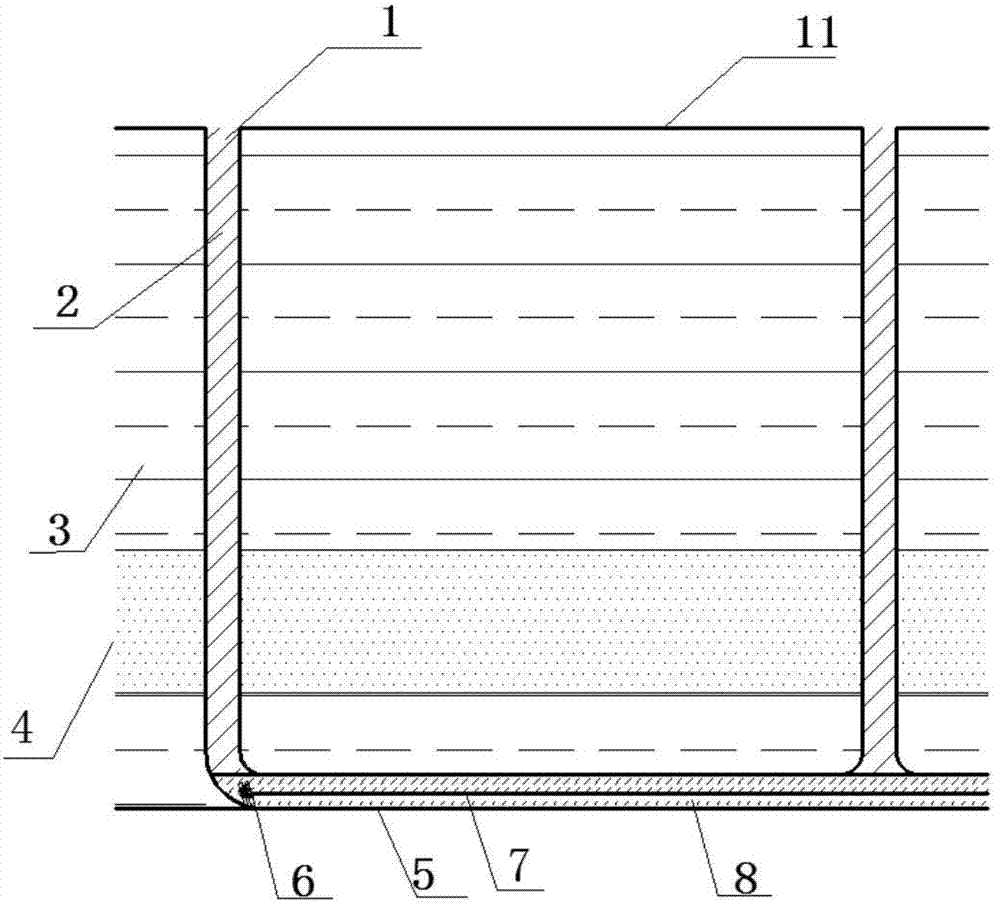

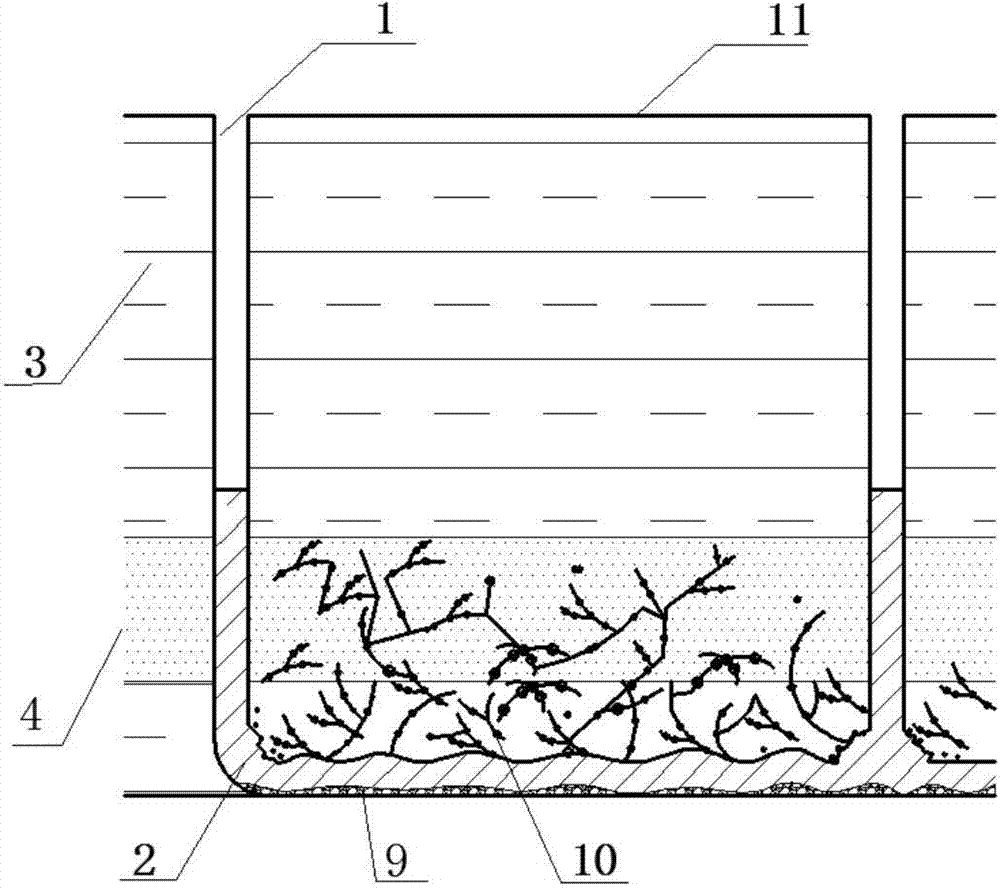

[0023] In this embodiment, a method for depressurizing and extracting gas by loosening and blasting coal seam floors by drilling holes on the ground includes the following steps:

[0024] (a) On the overlying surface of the working face along the advancing direction of the working face, drill the ground drilling 1 with a diameter of 75mm every 200m to the place 2m below the floor of the working face of the coal seam 4;

[0025] (b) Utilize the "L-shaped" drilling technology to drill a horizontal borehole 5 with a diameter of 75mm along the advancing direction of the working face at the bottom of the ground well 1, and the horizontal borehole 5 is connected to the adjacent ground well 1;

[0026] (c) explosives 8 are filled in the horizontal borehole 5 described in step (b), and run through adjacent explosives 8 with detonating cord 7, and explosives 8 are water-gel explosives;

[0027] (d) Injecting water into the surface drilling 1 in step (b) to seal the hole until it is flu...

Embodiment 2

[0031] In this embodiment, a method for depressurizing and extracting gas by loosening and blasting coal seam floors by drilling holes on the ground includes the following steps:

[0032] (a) On the overlying surface of the working face along the advancing direction of the working face, drill the ground drilling 1 with a diameter of 145mm every 300m to the place 3m below the floor of the working face of the coal seam 4;

[0033] (b) Utilize the "L-shaped" drilling technology to drill a horizontal borehole 5 with a diameter of 145mm along the advancing direction of the working face at the bottom of the ground well 1, and the horizontal borehole 5 is connected to the adjacent ground well 1;

[0034] (c) filling the explosive 8 in the horizontal borehole 5 described in the step (b), and passing through the adjacent explosive 8 with the detonating cord 7, and the explosive 8 is an emulsion explosive;

[0035] (d) Injecting water into the ground well 1 in step (b) to seal the hole ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap