Centering multidirectional movement structure of motorcycle stepless speed changing clutch

A technology of stepless speed change and motion structure, applied in the field of clutches, can solve problems such as seal rupture failure, steel sleeve and sliding sleeve wear, and achieve low manufacturing cost, improved work reliability, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

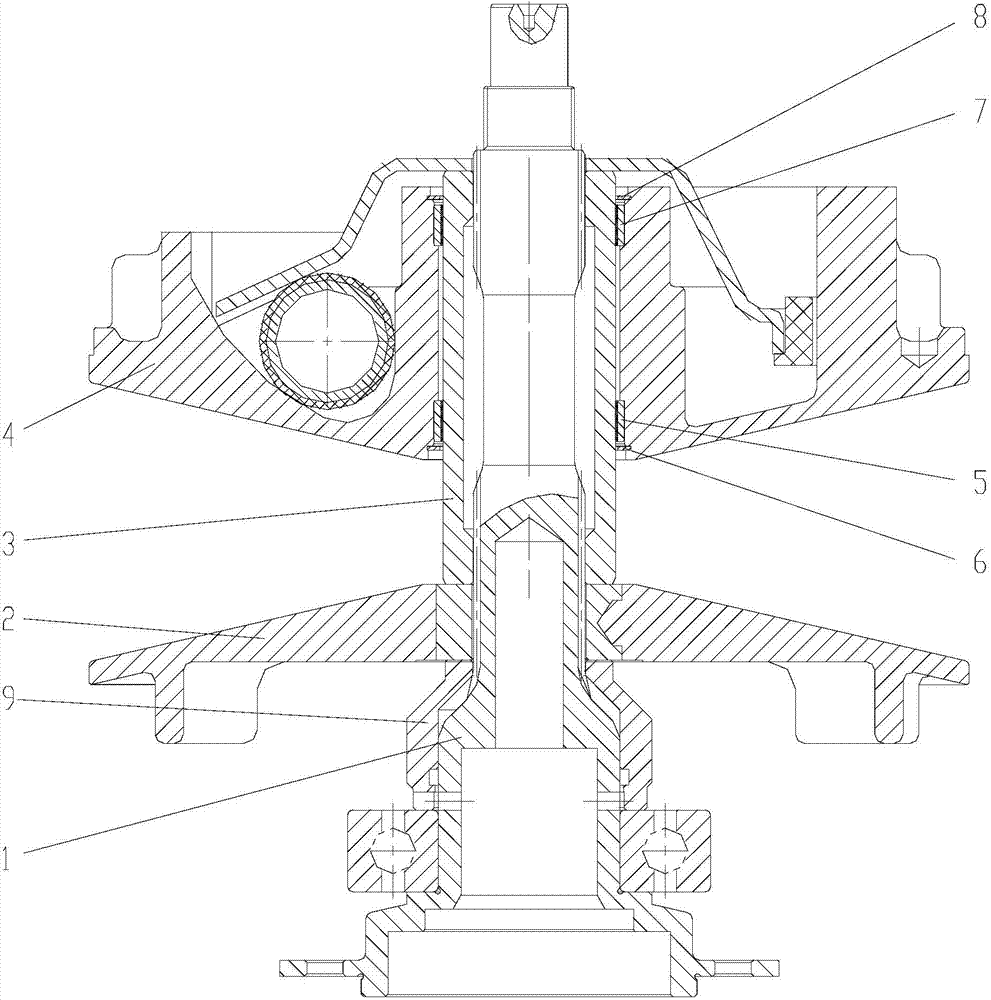

[0015] As shown in the figure, the centering and multi-directional movement structure of the motorcycle continuously variable transmission clutch in this embodiment includes a transmission shaft 1 and a drive disc 2 sleeved on the transmission shaft and splined with the transmission shaft. And the sliding sleeve 3 that is rotatably matched with the transmission shaft and the moving wheel 4 that is sleeved on the sliding sleeve, one end of the inner hole of the moving wheel is fixedly provided with a first sliding bearing 5 and a first stop that prevents the first sliding bearing from falling off in the axial direction. Ring 6, the other end of the inner hole of the moving wheel is provided with a second sliding bearing 7 and a second retaining ring 8 to prevent the second sliding bearing from falling off in the axial direction, the first sliding bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com