A kind of conveying trolley and ems conveying system

A technology for conveying trolleys and trolleys, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc. It can solve the problems of increasing the manufacturing and transportation costs of EMS conveying systems, the complex load-carrying structure of carrying trolleys, and affecting the efficiency of conveying workpieces. The effect of manufacturing and transportation costs, improving efficiency, and simple load-carrying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present application provides a conveying trolley, which has a simple load-carrying structure, small weight and volume, and can quickly and stably convey objects, thereby reducing the manufacturing and conveying costs of the EMS conveying system and improving the efficiency of conveying workpieces.

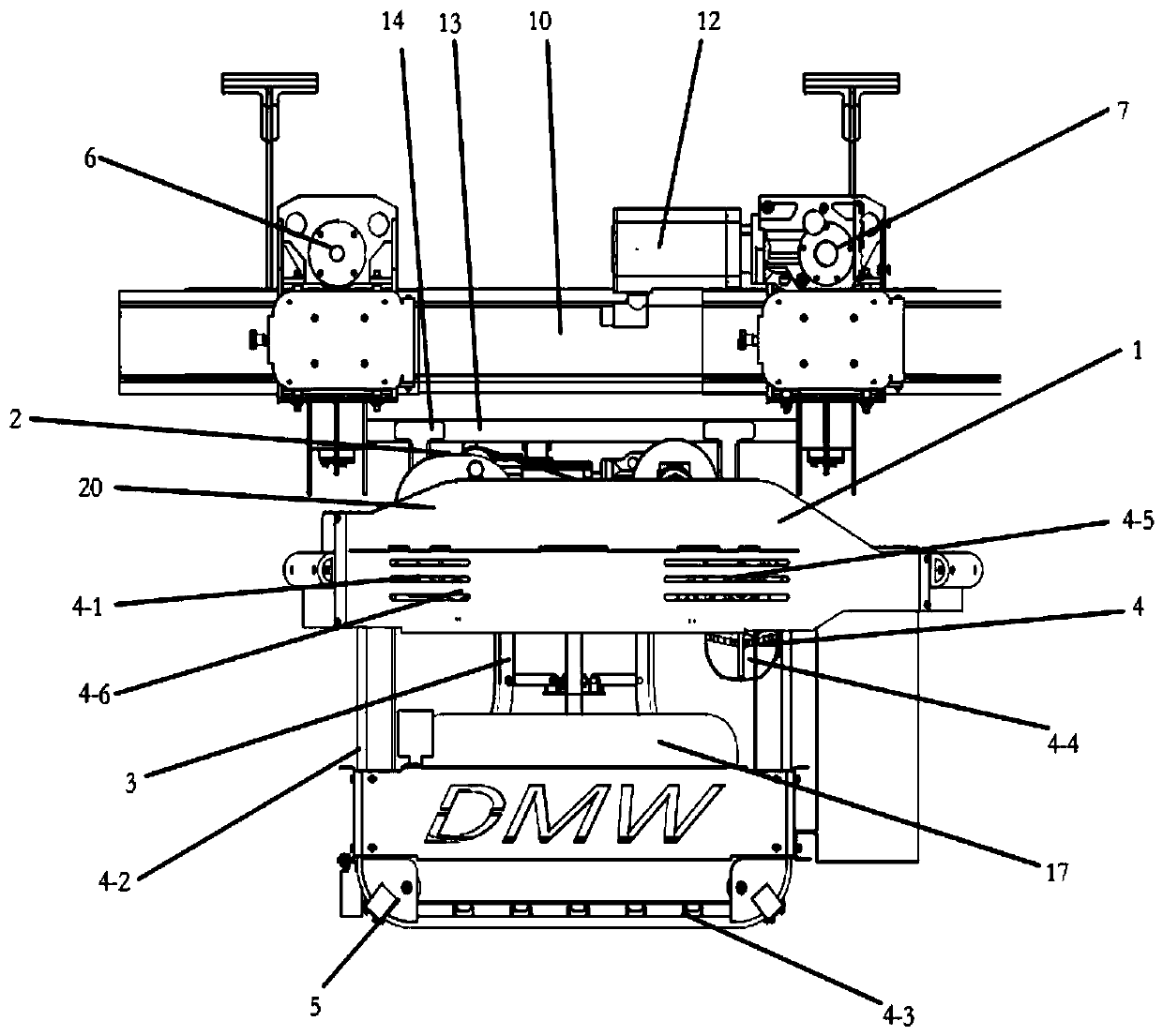

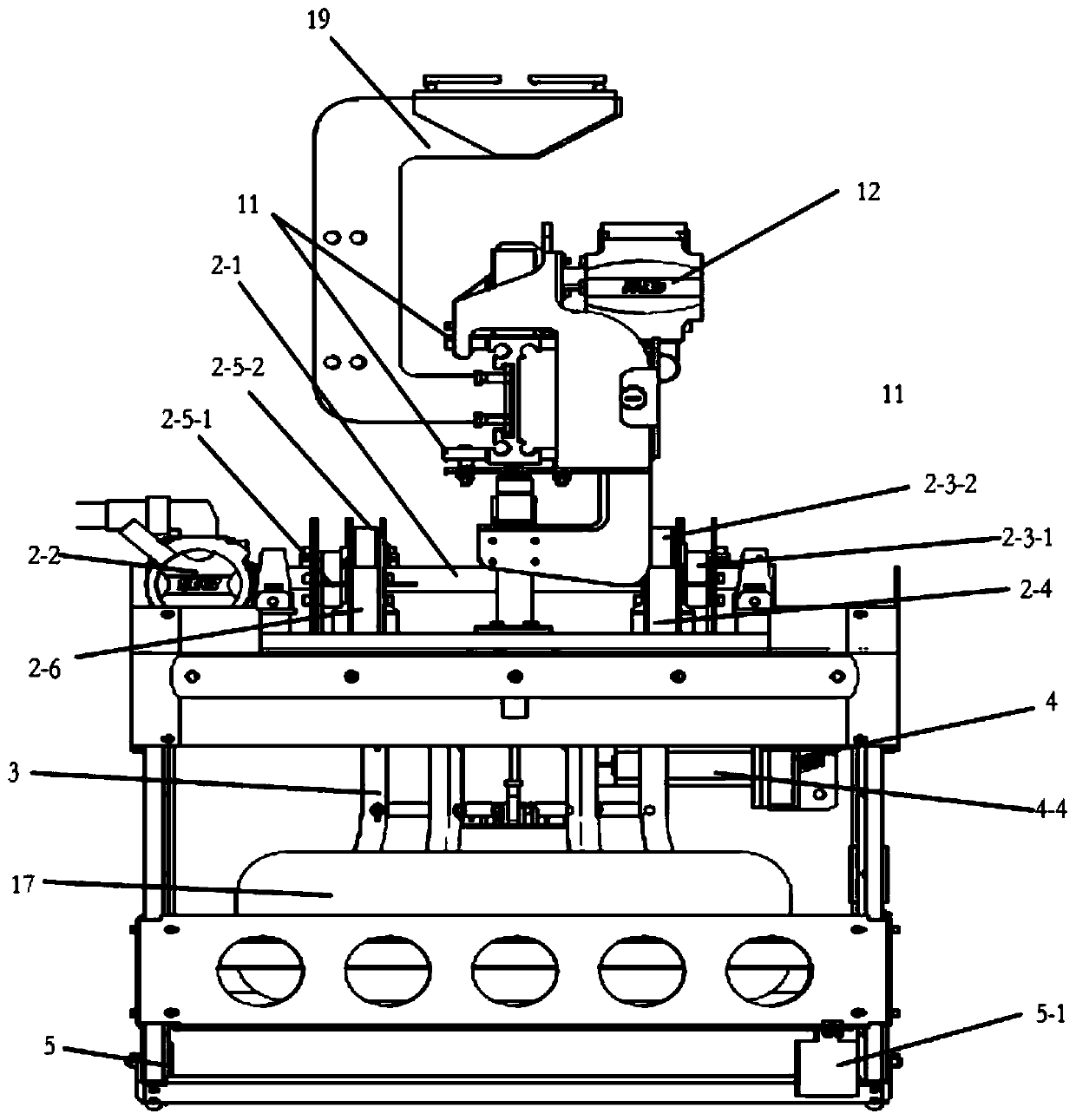

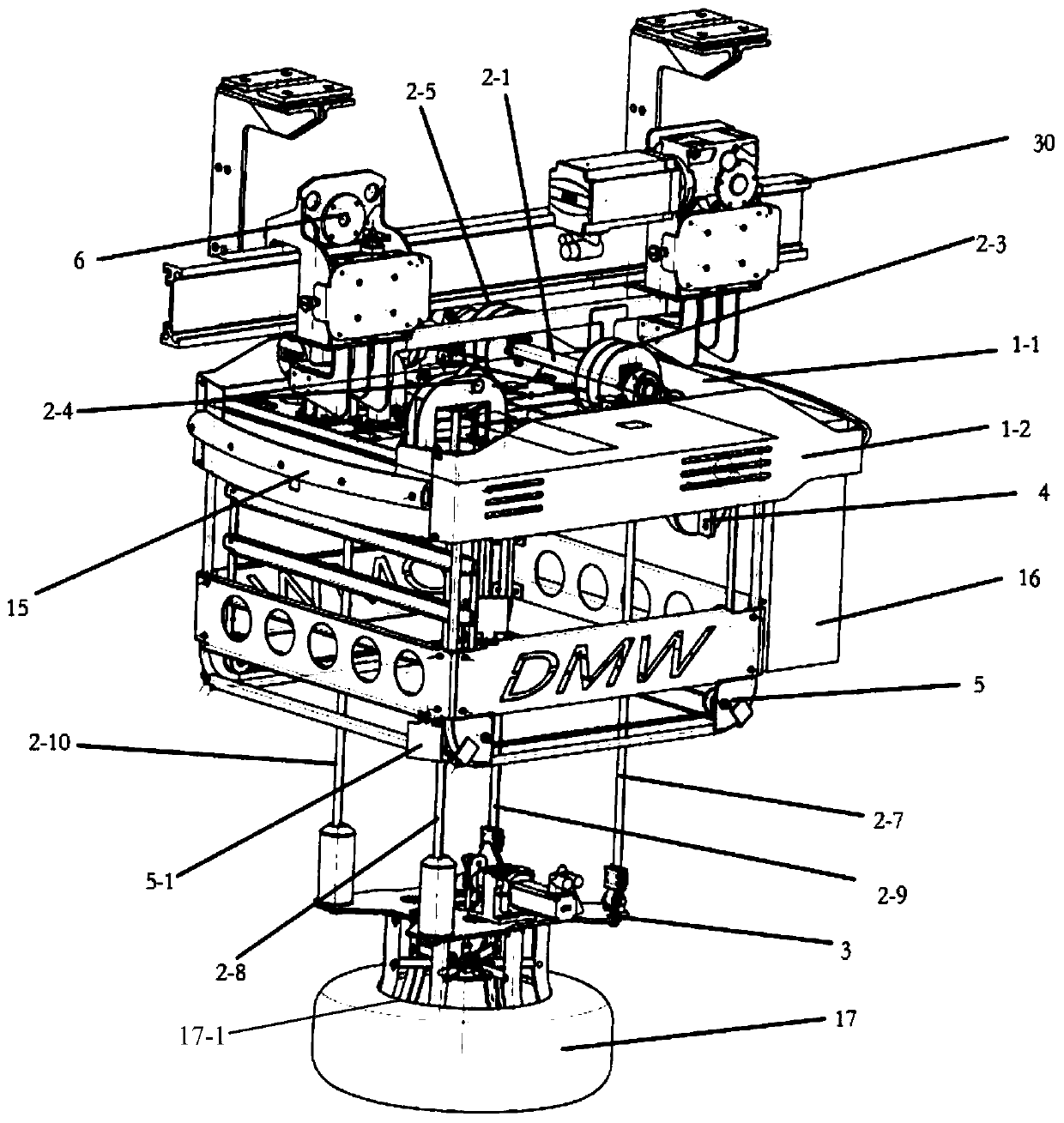

[0039] Such as figure 1 , figure 2 As shown, the conveying trolley 20 includes a trolley body 1, and a lifting mechanism 2 and a clamping mechanism 3 that can move with the trolley body 1;

[0040] The trolley body 1 has traveling wheels, and the trolley body 1 can reciprocate along the trolley track 10 driven by the traveling wheels; in order to make the conveying trolley 20 run quickly and smoothly, the traveling wheels are set There are two, including the first road wheel 6 and the second road wheel 7, the first road wheel 6 and the second road wheel 7 are installed through the first supporting base 8 and the second supporting base 9 respectively, and are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com