Aerial framework operation toolbox

A technology for operating tools and boxes, which is applied in the direction of switchgear, electrical components, etc., can solve the problems of inconvenient lighting for nighttime work, and achieve the effects of reducing the risk of tool falling, easy to use, and easy to take and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

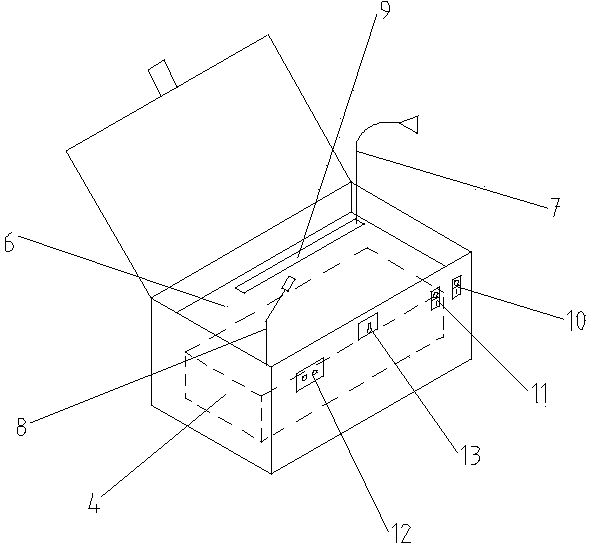

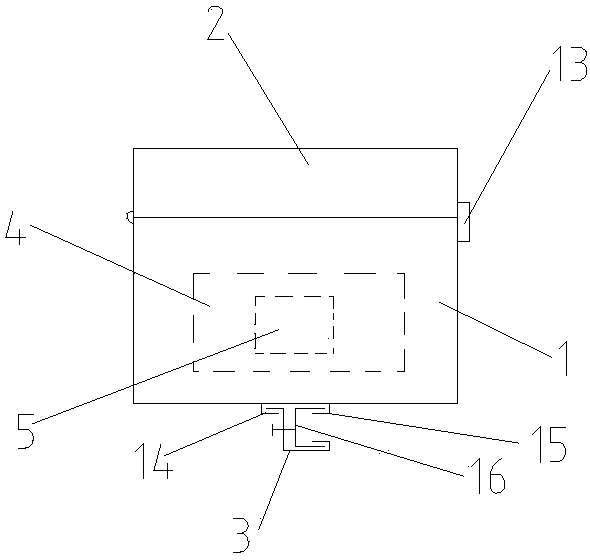

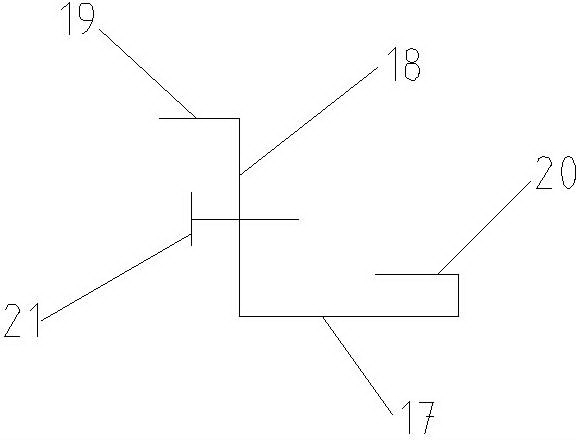

[0022] Such as figure 1 , 2 Shown in and 3, a kind of high-altitude structure work toolbox, it is made up of box body 1 and box cover 2, box body 1 and box cover 2 are hinged, box lock 13 is provided between box body 1 and box cover 2, box body 1. There is a channel steel connection device at the bottom. The channel steel connection device consists of an auxiliary part 3 independent of the box body 1, a first fitting hook 15 fixed at the bottom of the box body 1, and an auxiliary part fitting groove fixed at the bottom of the box body 1. 14, and fastening screws 21, the main body of the auxiliary part 3 is an angle steel, the end of the first leg 18 of the angle steel has an extension edge 19, the extension direction of the extension edge 19 is opposite to the extension direction of the second leg 17 of the angle iron, The end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com