Dicyclopentadiene based resin compositions and articles manufactured therefrom

A technology of dicyclopentadiene and methylcyclopentadiene is applied in the field of resin compositions based on dicyclopentadiene and products manufactured therefrom, and can solve problems such as negative rolling resistance, influence and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

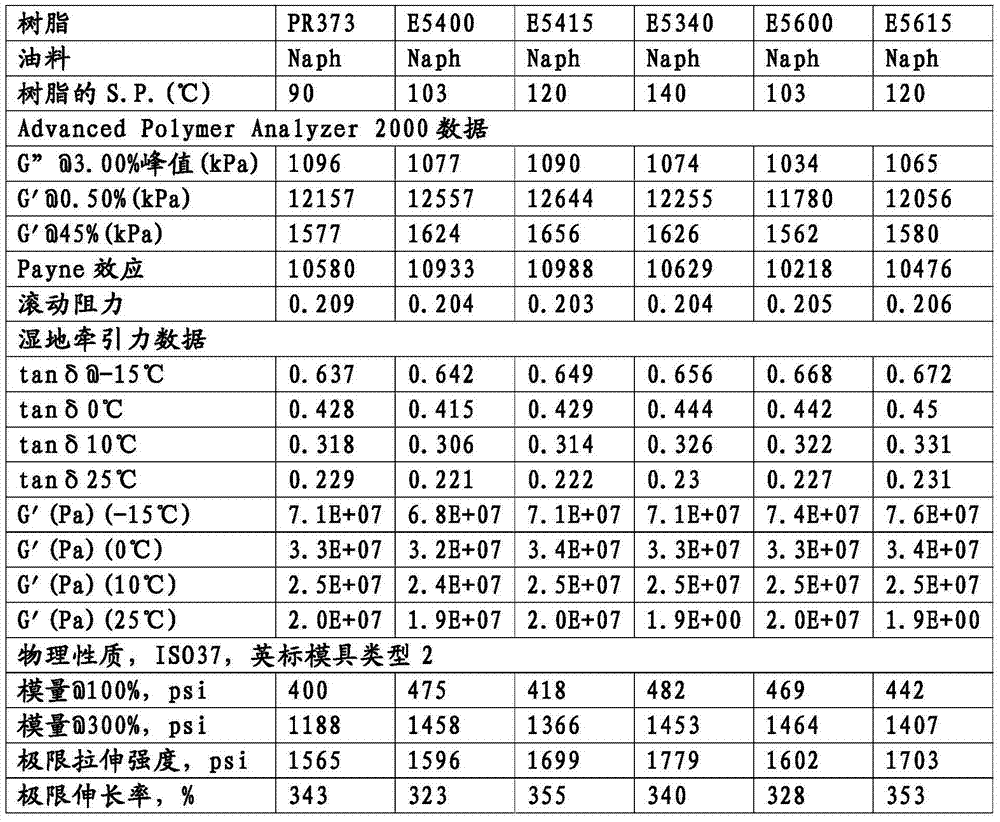

[0072] In the following examples:

[0073] "PR 373" is based on Oppera TM 373 Hydrocarbon polymer additive available from ExxonMobil Chemical Company. It has a softening point of 89°C, a weight average molecular weight of about 1500 g / mole, and a dicyclopentadiene / cyclopentadiene / methylcyclopentadiene content of less than 40 wt%.

[0074] "E5400" is based on Escorez TM 5400 Hydrocarbon polymer additive available from ExxonMobil Chemical Company. It has a softening point of 103°C, a weight average molecular weight of about 400 g / mole, and a dicyclopentadiene / cyclopentadiene / methylcyclopentadiene content of 40-80 wt%.

[0075] "E5415" is based on Escorez TM 5415 Hydrocarbon polymer additive available from ExxonMobil Chemical Company. It has a softening point of 118°C, a weight average molecular weight of about 430 g / mole, and a dicyclopentadiene / cyclopentadiene / methylcyclopentadiene content of 40-80 wt%.

[0076] "E5340" is based on Escorez TM 5340 Hydrocarbon polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com