Automatic broiler breeder raising greenhouse for polyculture and separate feeding of roosters and hens

A technology for mixing male and hens, applied in the field of poultry breeding industry, can solve the problems of artificial insemination time-consuming, labor-intensive, susceptible to infection, etc., to achieve the effects of improving welfare, optimizing the breeding environment, and solving the bottleneck of time-consuming, labor-intensive and susceptible to infection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

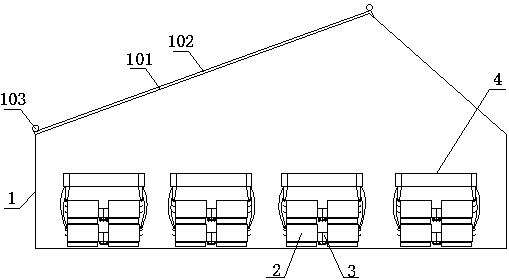

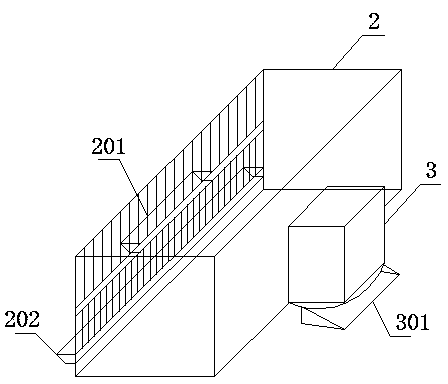

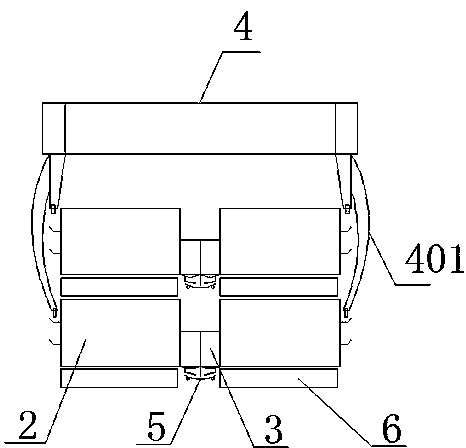

[0028] Such as figure 1 As shown, the overall structure of the present invention includes a greenhouse 1 and several rearing units inside. The illuminated surface of the greenhouse 1 forms a small included angle of 10°-30° with the horizontal plane. The heat preservation cover layer 102 is arranged on the illumination surface 101 and is automatically rolled out by a motor 103 controlled by a temperature sensor in the shed; the heat preservation cover layer 102 is an opaque and anti-seepage heat preservation material. When it is rolled up, the sunlight fully irradiates the inside of the shed, which makes the temperature inside the shed rise, and when it is unfolded, it can cover the sun and play a role of heat preservation. In summer, according to the actual situation, the temperature difference between the upper and lower limits of the thermostat can be appropriately redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com