Device for removing short down and dust accumulated at bellmouth of coiler of cotton carding machine

A technology of cleaning device and sliver coiler, which is applied in deburring device, fiber treatment, textile and paper making, etc. It can solve the problems affecting yarn quality, loss of yarn return, end breakage and so on, so as to ensure the quality of sliver, improve production efficiency and The effect of product benefits

Inactive Publication Date: 2015-02-11

王昌宏

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the production process of the carding machine in the prior art, a lot of linters and dust accumulate at the bell mouth of the coiler, which will adhere to the raw sliver intermittently, causing yarn defects in the downstream, affecting the quality of the yarn, resulting in drawing, Broken ends of roving and spun yarns, increase in the number of cuts in the winding machine, resulting in loss of returned wire

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

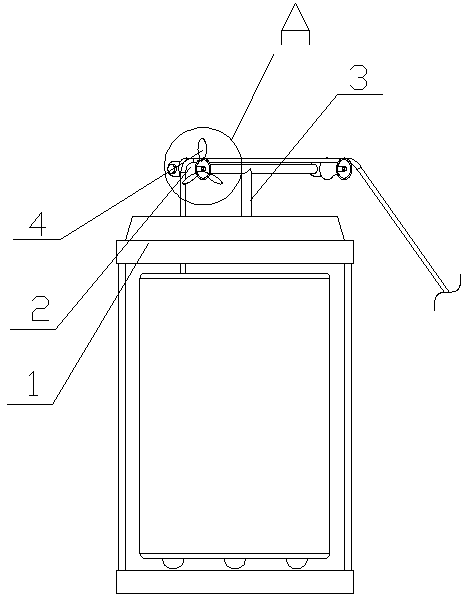

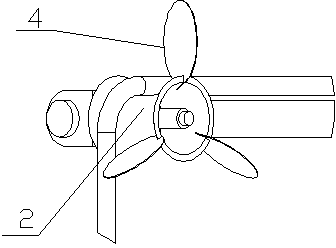

[0008] Such as figure 1 , 2 As shown, the present invention includes a sliver coiler 1, a guide wheel 2 is installed directly above the sliver coiler 1 through a bracket 3, and three elliptical rotating blades 4 are evenly distributed on the upper circumference of the guide wheel 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a device for removing short down and dust accumulated at a bellmouth of a coiler of a cotton carding machine and belongs to the field of spinning machinery. The device comprises the coiler, and a carded sliver guide wheel is mounted right above the coiler through a support. The device is characterized in that three oval rotating blades are uniformly distributed on the carded sliver guide wheel circumferentially. The oval rotating blades are uniformly distributed on the carded sliver guide wheel on the coiler circumferentially; when running along with carded slivers, the carded sliver guide wheel on the coiler drives the rotating blades to rotate, the rotating blades which rotate form a small fan, short down and dust which are generated newly in the process of production can be removed, quality of the carded slivers is guaranteed, and production benefit and product benefit are improved.

Description

technical field [0001] The invention belongs to the field of textile machinery, and in particular relates to a device for removing linters and dust at the bell mouth of a coiler of a carding machine. Background technique [0002] In the production process of the carding machine in the prior art, there is a lot of cotton linters and dust accumulation at the bell mouth of the coiler, which will be attached to the raw sliver intermittently, causing yarn defects in the downstream, affecting the quality of the yarn, resulting in drawing, The roving and spun yarns break, and the shear number of the winding machine increases, resulting in the loss of returned silk. Contents of the invention [0003] The purpose of the present invention is to provide a method that can timely remove the linters and dust generated during production, effectively ensure the quality of card sliver, and improve production efficiency and product benefits. Clear device. [0004] The technical soluti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01G15/82

CPCD01G15/82

Inventor 王昌宏

Owner 王昌宏

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com