A four-color printing method for dark-color fabric of garments

A printing method and four-color separation technology, which is applied in the field of garment processing, can solve the problems of physical discomfort, poor hand feeling, and difficulty in mass production, and achieve the effect of soft hand feeling, comfortable body feeling and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

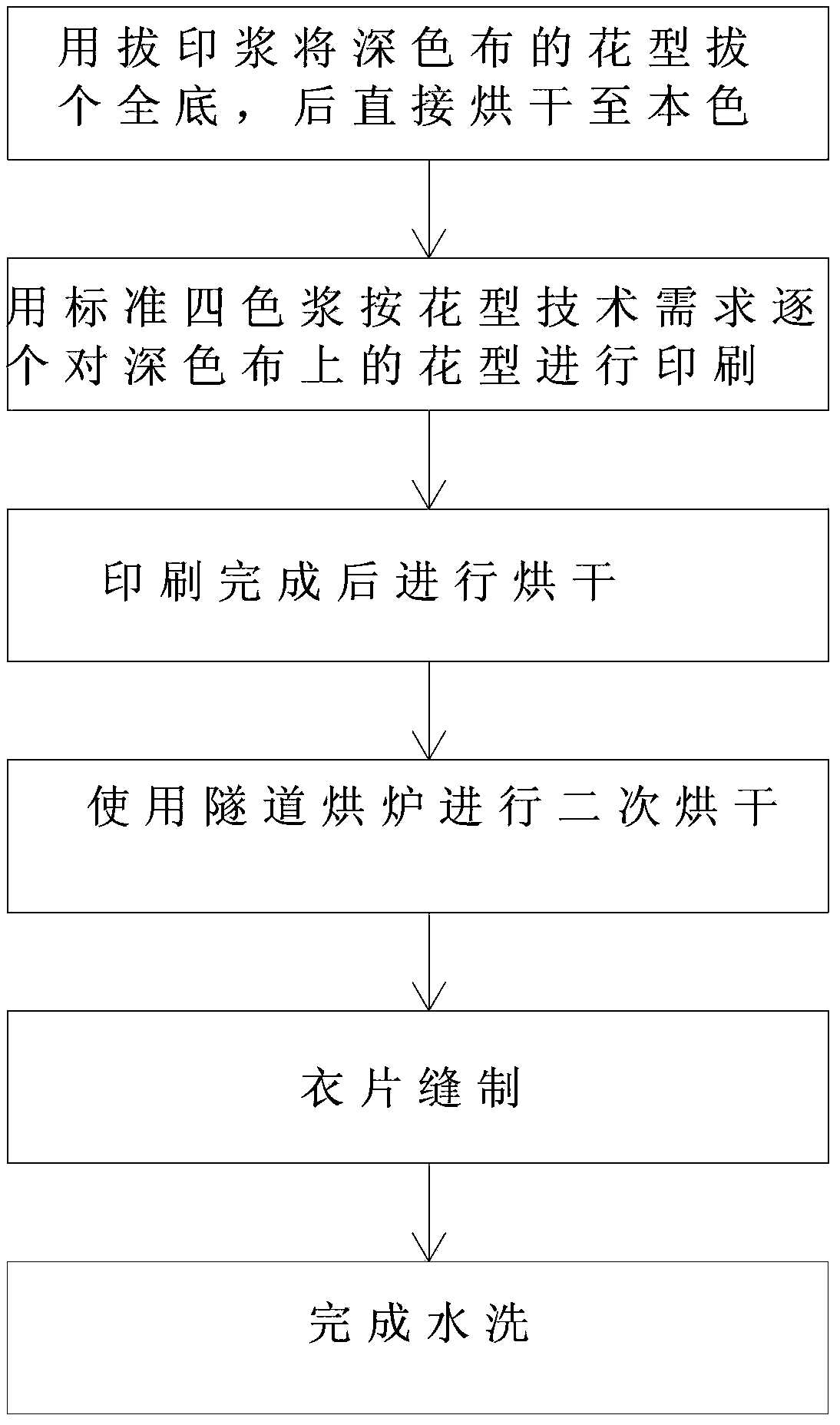

[0014] See figure 1 , The four-color printing method for dark clothing fabrics of the present invention includes the following steps:

[0015] 1) First use the printing paste to pull the dark cloth to the bottom of the pattern that needs to be printed, and then directly dry it to its original color in a platen oven;

[0016] 2) Use standard four-color paste to print the patterns on the dark cloth one by one according to the technical requirements of the pattern;

[0017] 3) Drying after printing;

[0018] 4) Use a tunnel oven for secondary drying;

[0019] 5) Carry out the sewing of garment parts;

[0020] 6) Carry out washing operation.

[0021] The discharging material used in the process of drawing the whole bottom of the pattern is a suitable discharging material selected according to different fabrics and fabric colors. The printing method of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com