Circular screen copy-jeting wax and making method thereof

A technology of rotary screen and paraffin wax, which is applied in the field of computer rotary screen plate-making and its manufacturing field. It can solve the problems of difficult to print fine patterns, easy to produce seams, and low plate-making accuracy, so as to achieve realistic patterns. , smooth edges, clear mesh effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

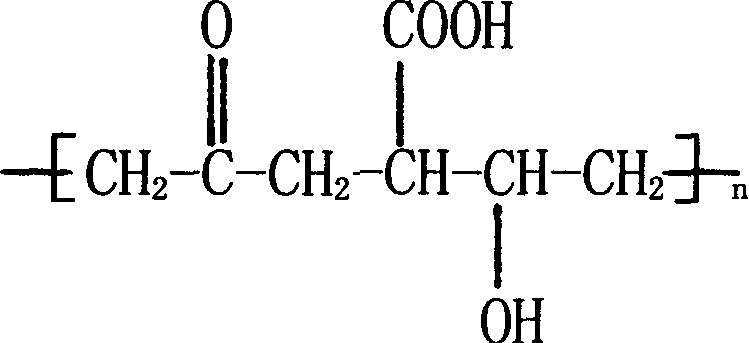

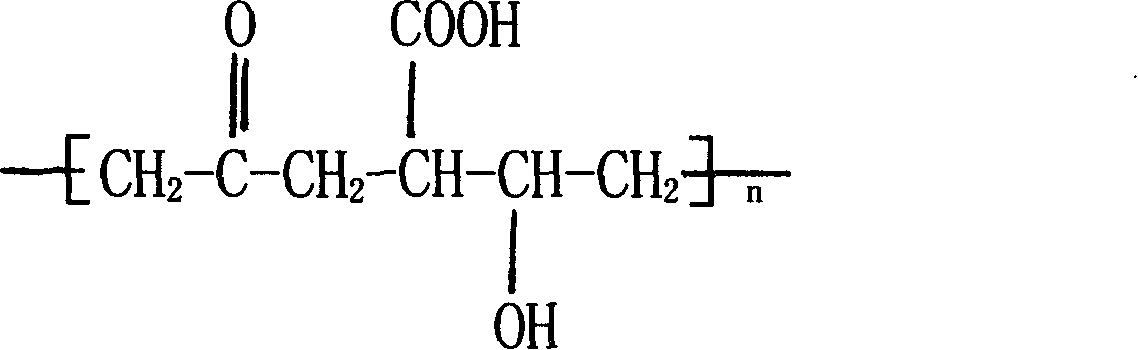

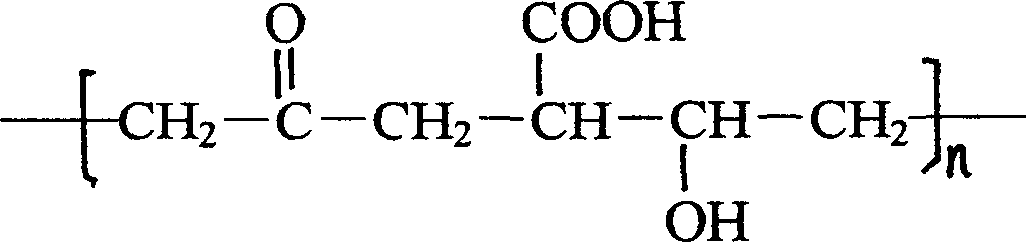

Method used

Image

Examples

example 1

[0045] Weigh raw materials according to the following proportions:

[0046] 1.5 kg of oxyalkylene polymer,

[0047] 5 kg of high molecular hydrocarbons with a melting point of 82.5°C,

[0048] 3 kg of high molecular hydrocarbons with a melting point of 59-65°C,

[0049] Rosin pentaerythritol ester binder 0.2 kg,

[0050] Black pigment 0.3 kg.

[0051] Make rotary screen spray wax as follows:

[0052] A. First, heat the rosin pentaerythritol ester to 120° C. to melt into a viscous body, and gradually add 0.4 kg of organic solvent ethanol dropwise, and stir while adding, until it is evenly diluted, and the rosin pentaerythritol ester adhesive is made;

[0053] B. Mix the oxyalkylene polymer and the black pigment, put it into the reaction kettle and raise the temperature to 150°C while stirring, and keep the temperature constant for 2-3 hours;

[0054] C. Put in high molecular hydrocarbons with a melting point of 82.5°C and high molecular hydrocarbons with a melting point of...

example 2

[0059] Weigh raw materials according to the following proportions:

[0060] 1.8 kg of oxyalkylene polymer,

[0061] 51 kg of high molecular hydrocarbons with a melting point of 82.5°C,

[0062] 2.4 kg of high molecular hydrocarbons with a melting point of 59-65°C,

[0063] Rosin pentaerythritol ester binder 0.3 kg,

[0064] Black pigment 0.4 kg.

[0065] The method is the same as Example 1.

example 3

[0067] Weigh raw materials according to the following proportions:

[0068] Oxygenated polymer 2 kg

[0069] High molecular hydrocarbon with a melting point of 82.5°C 5 kg

[0070] Melting point 59-65 ℃ polymer hydrocarbon 2 kg

[0071] Rosin pentaerythritol ester binder 0.5 kg

[0072] Black pigment 0.3 kg.

[0073] The method is the same as Example 1. The wax sprayed on the rotary screen produced by the above-mentioned manufacturing method has no precipitation phenomenon, is easy to filter, does not block the nozzle, and has a good net-making effect by spraying the wax.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com