Crystal lamp light source

A technology of crystal lamp and lamp source, applied in electric light source, light source fixing, lighting device and other directions, can solve the problem of poor light refraction effect, etc., and achieve the effect of improving dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the drawings. The directional terms mentioned in the following embodiments, such as: up, down, left, right, front or back, etc., are only directions referring to the attached drawings. Accordingly, the directional terms are used to illustrate and not to limit the invention.

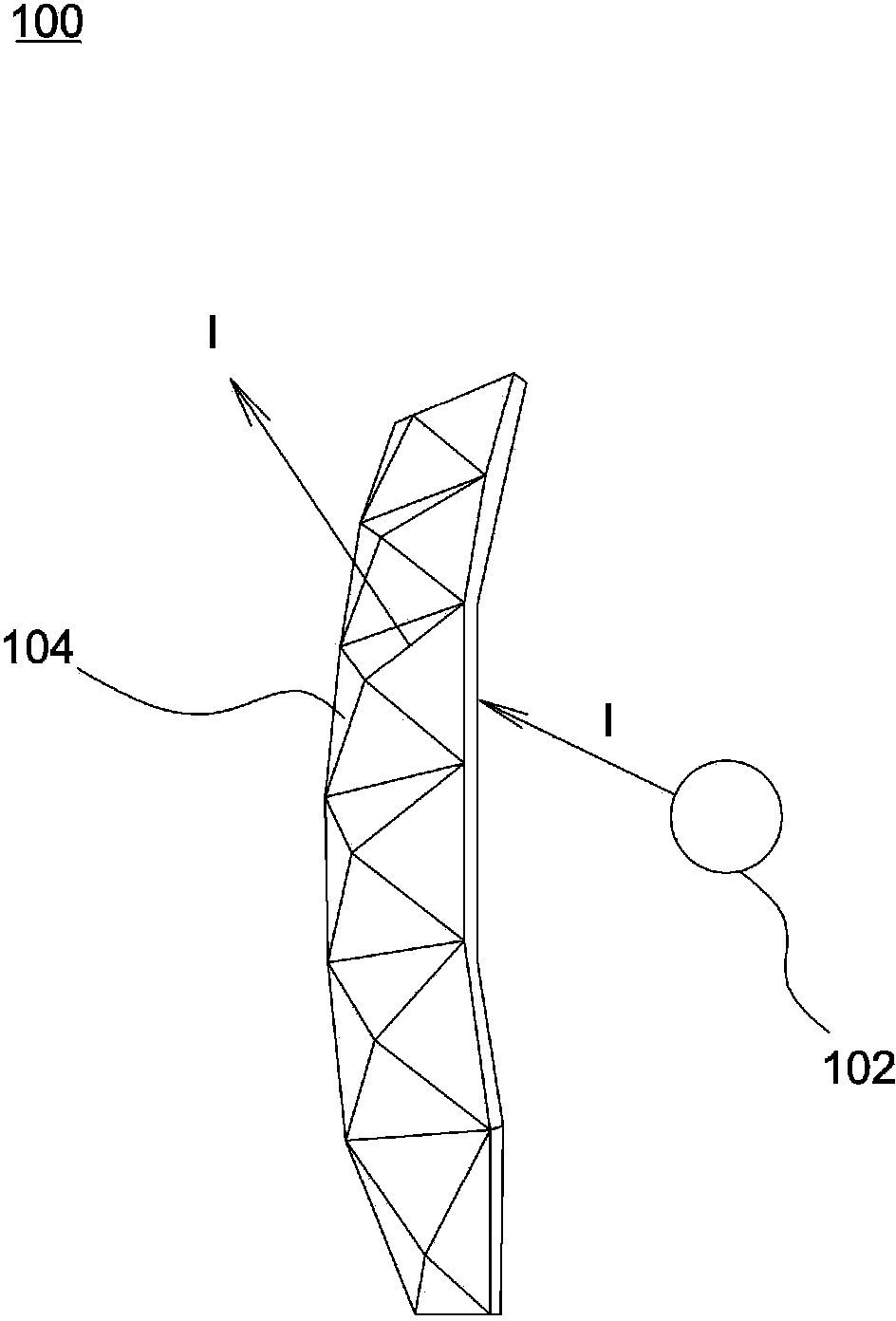

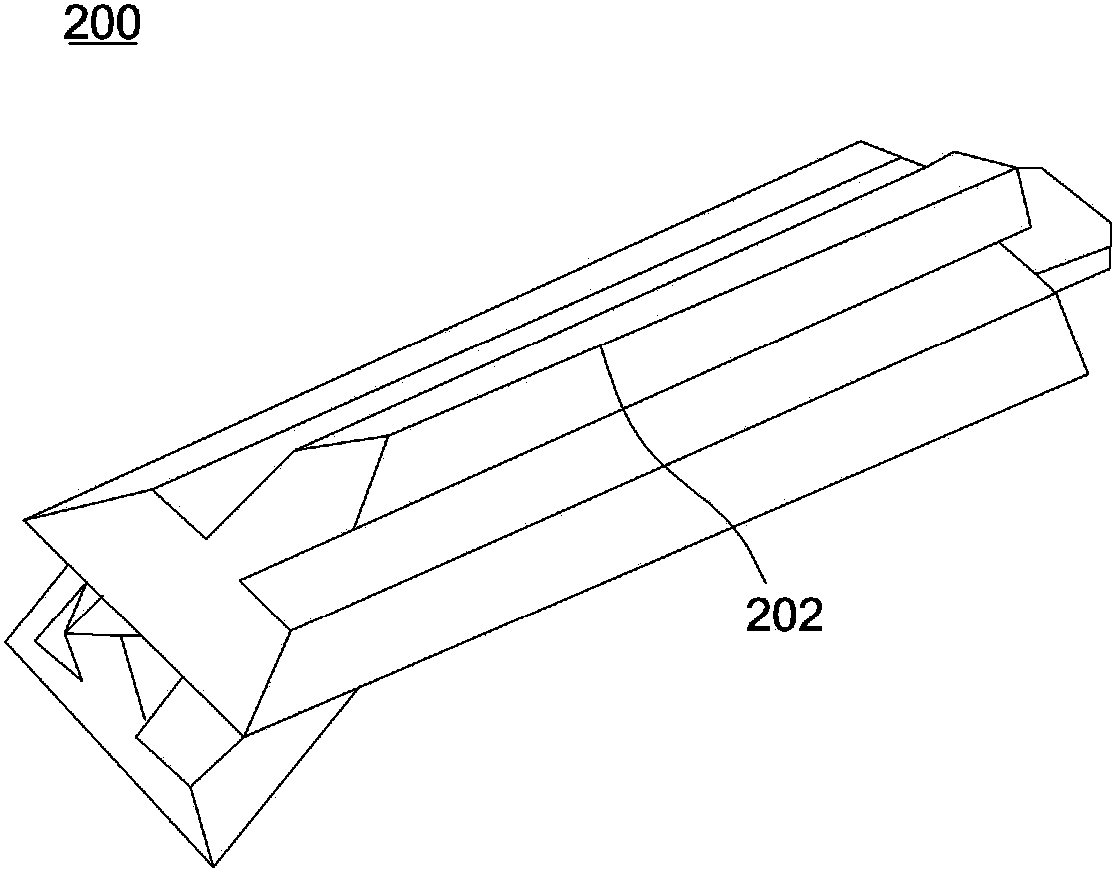

[0047] Figure 4 It is a schematic diagram of a crystal light source of an embodiment of the present invention, such as Figure 4 As shown, the crystal light source 10 includes a light guide column 12 , a base 14 and a light emitting element 16 . The light guide column 12 has a top surface 12a and a bottom surface 12b opposite to each other, and a side surface 12c connected between the top surface 12a and the bottom surface 12b. The side surface 12c is a curved surface concave toward the inside of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com