Fume collection compartment type range hood

A technology for range hood and smoke collecting compartment, which is applied in the direction of removing oil fume, household heating, lighting and heating equipment, etc., can solve the problems of oil fume, complete discharge of odor, messiness, inability to meet interior design, etc., and avoid strong wind blowing. The effect of extinguishing the fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

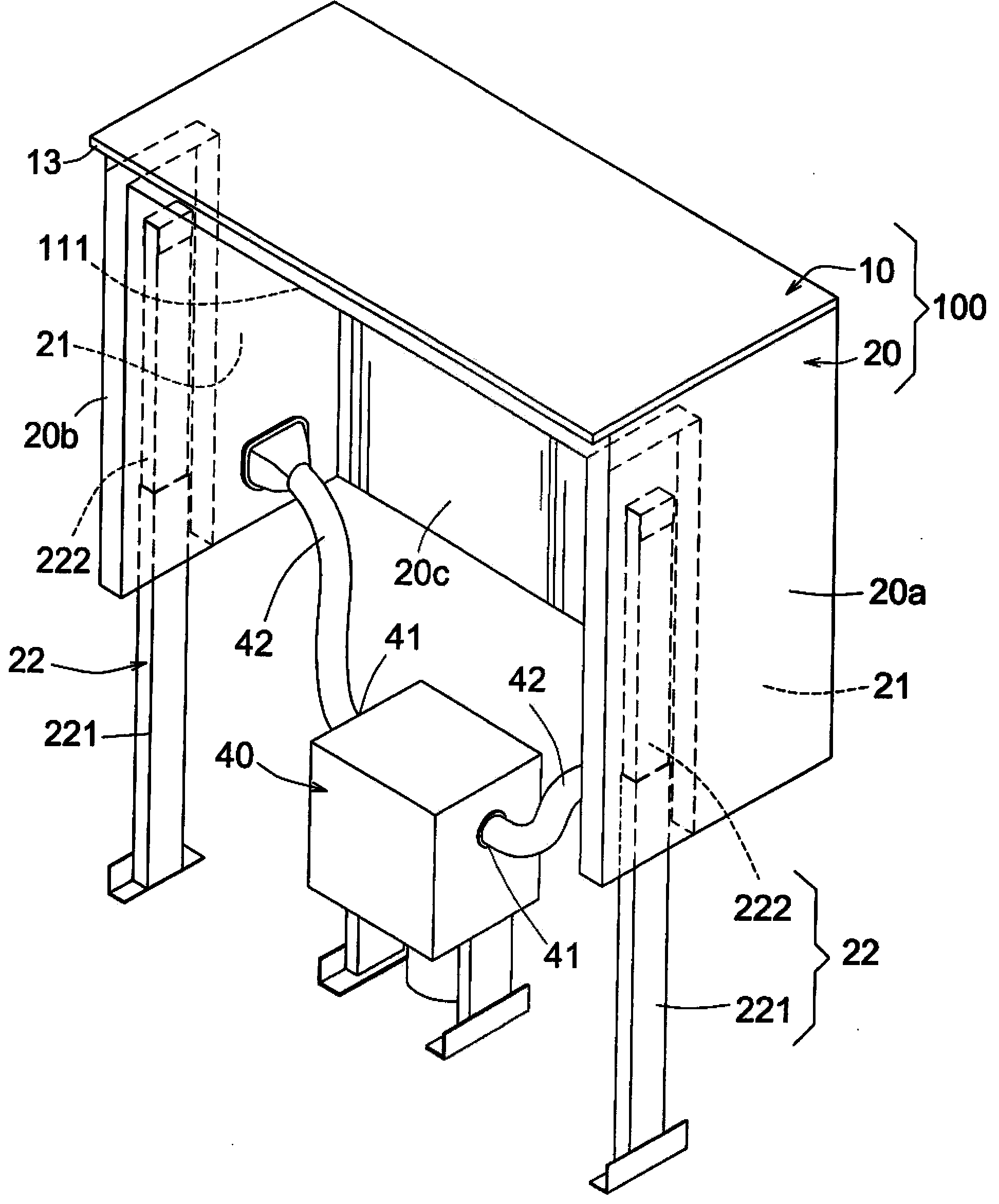

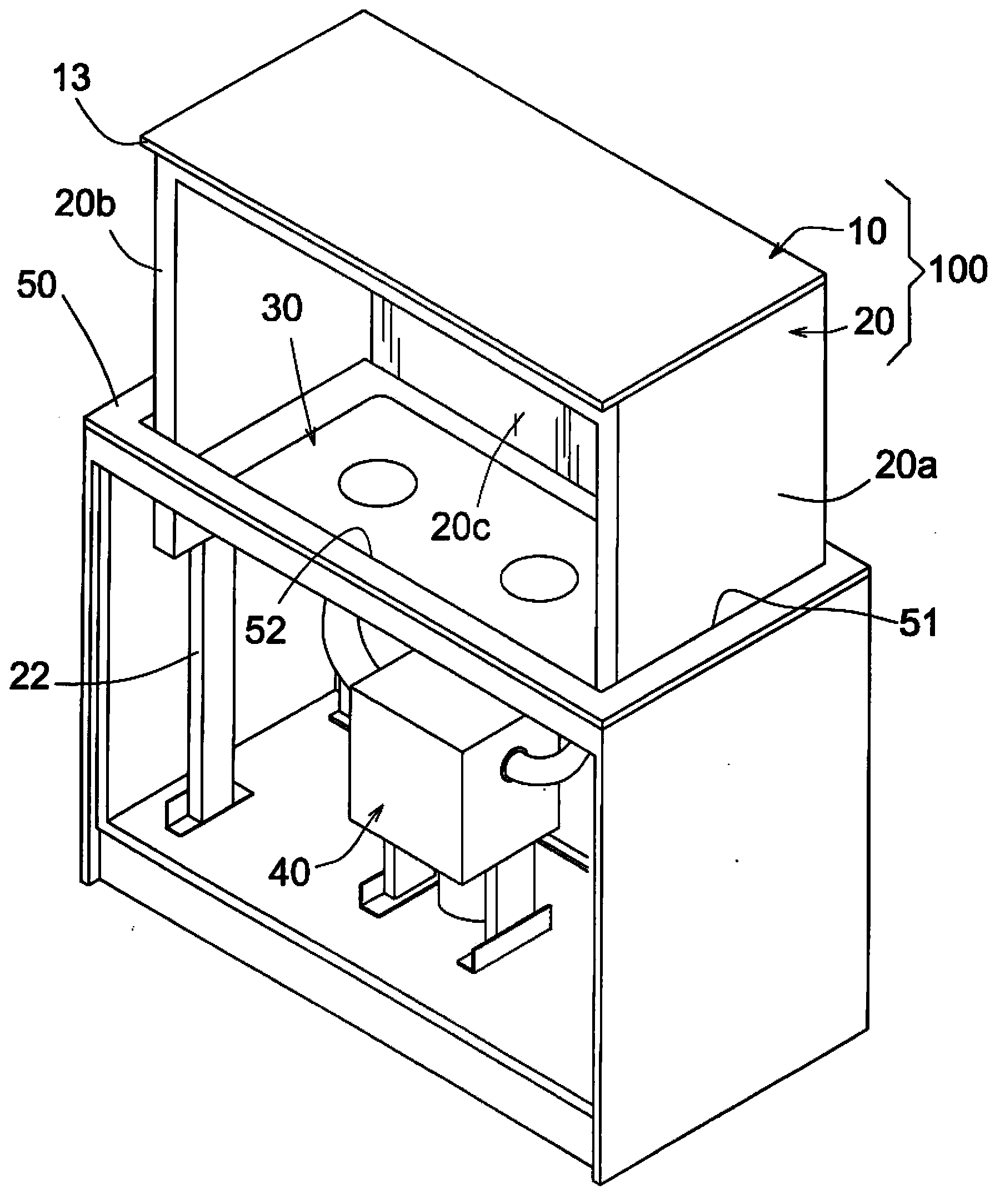

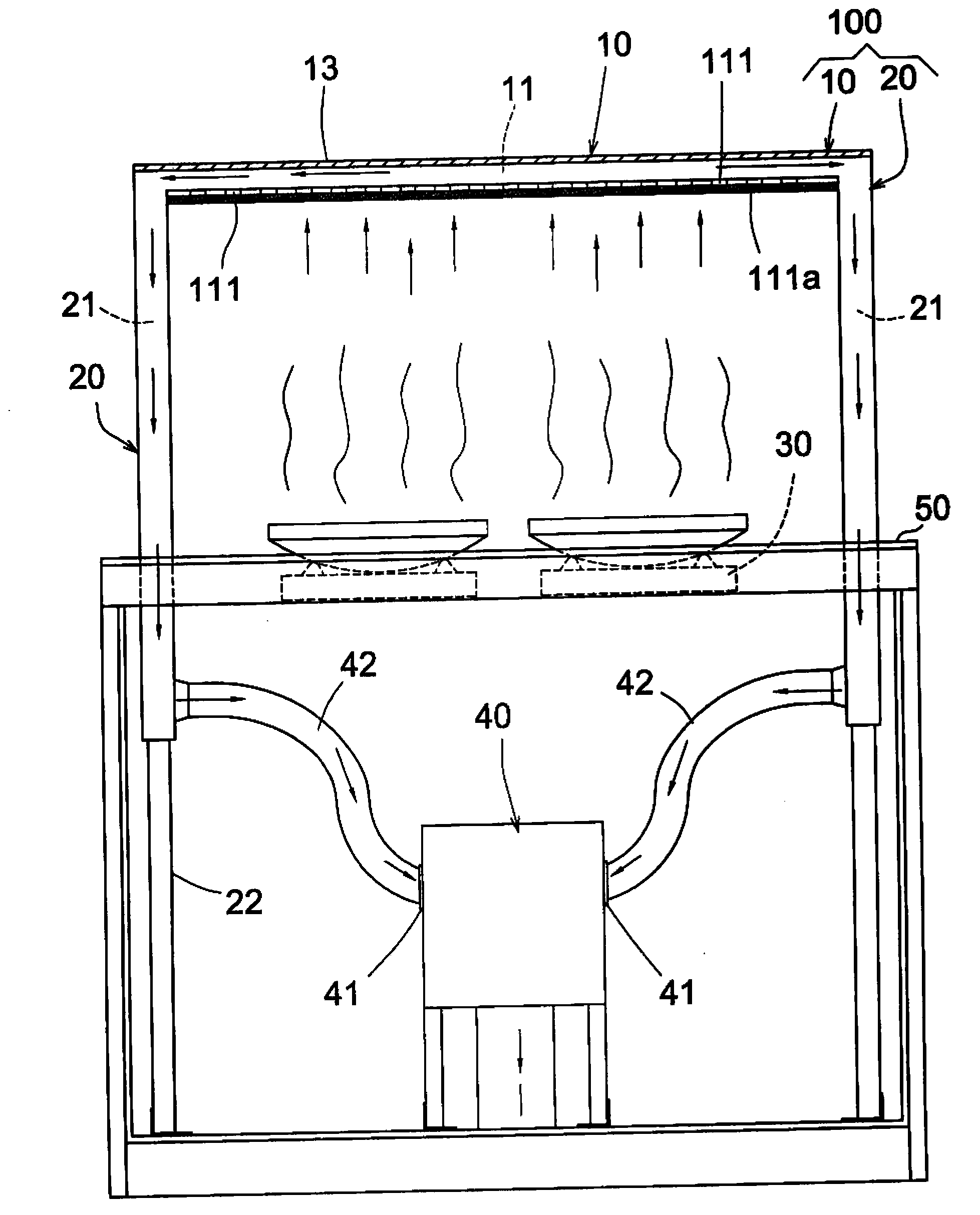

[0039] see figure 1 , figure 2 and image 3 As shown, the present invention relates to a smoke collecting box type range hood, which includes a top frame 10 and a side wall 20 protruding downward from the top frame 10, wherein the side wall 20 is framed around a stove The position of the left side, the right side and the rear side of 30 makes a smoke collection box 100 jointly formed by the stove 30 to the top frame 10 and the side wall 20, and the inner surface of the smoke collection box 100 is provided with an oil suction port 111 , and connect the oil suction port 111 to the air suction port 41 of a draft motor 40; in this way, the inside of the smoke collecting chamber 100 forms a negative pressure zone with a lower pressure than the outside, so that it can effectively limit the fumes and odors from drifting freely, making cooking The fumes and odors produced during the operation can be fully and thoroughly sucked by the exhaust motor 40 and discharged to the collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com