Pre-mixed sour gas flare burner

A flare combustion and acid gas technology, applied in the field of premixed acid gas flare burners, can solve the problems of substandard emission, personal injury, environmental pollution, etc., shorten the axial length, increase the flammability, and improve the burnout rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the technical content of the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

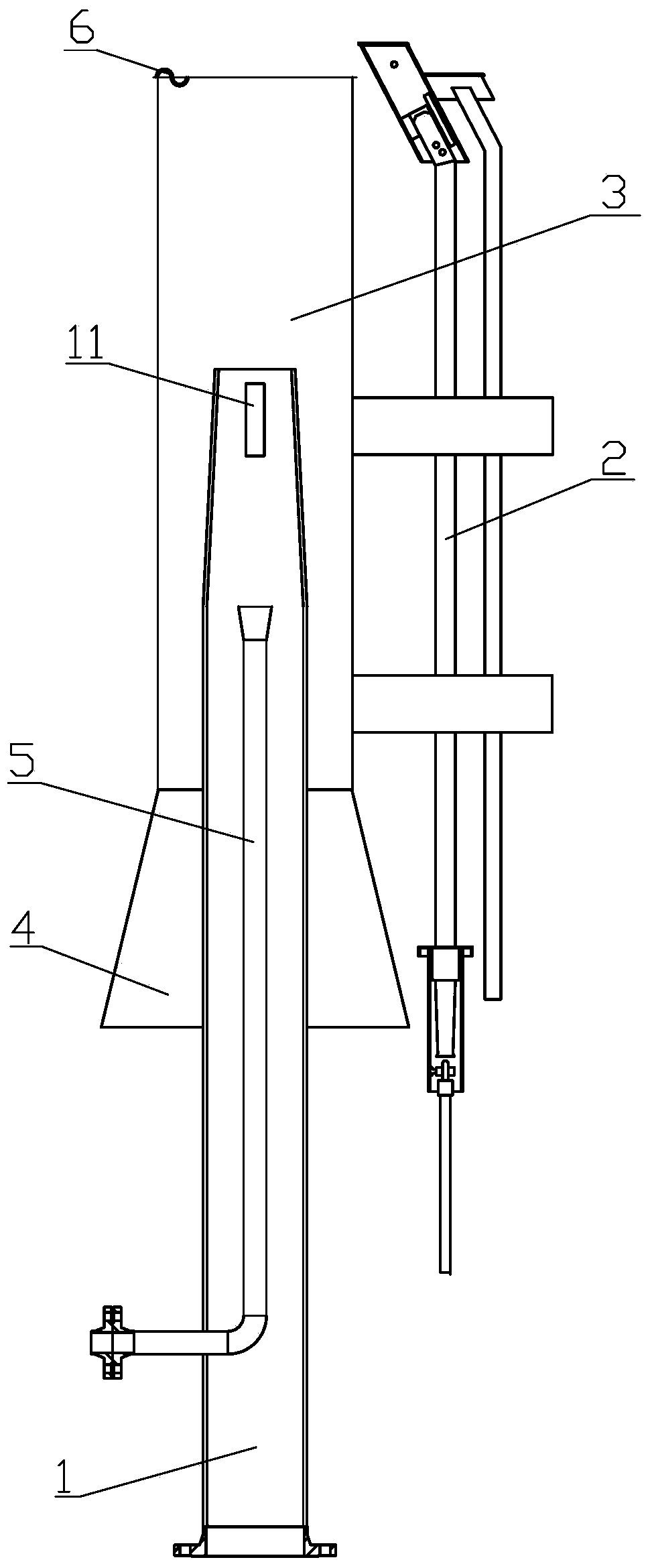

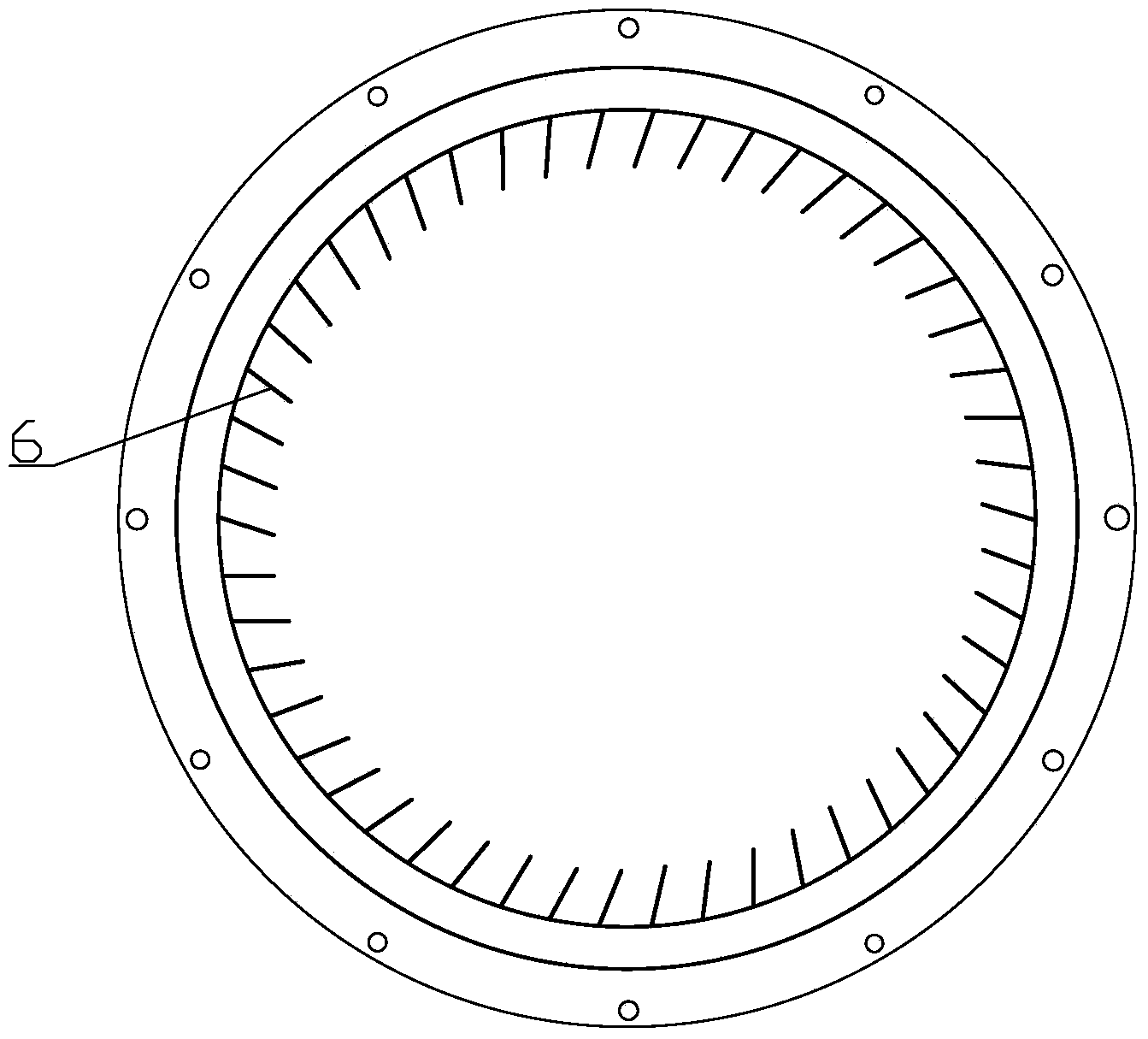

[0023] Such as figure 1 with figure 2 As shown, a premixed acid gas torch burner includes an air intake cylinder 1, an ignition lamp assembly 2, a premixed combustion chamber 3, a draft hood 4, a combustion-supporting gas delivery pipe 5 and an S-shaped porous fire gathering block.

[0024] The air intake cylinder 1, the premixing combustion chamber 3, the draft cover 4 and the gas-supporting delivery pipe 5 are all arranged axially, and preferably coaxially. Wherein the draft hood 4 is arranged at the lower end of the premix combustion chamber 3 .

[0025] The air-introducing hood 4 is in the form of a constriction, with its flaring end facing downwards and its constricting end facing upwards, so as to ensure that sufficient air can be injected int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com