Ammonia gas burner

A burner and ammonia technology, applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problems of poor combustion stability, poor ammonia stability, low ammonia conversion rate, etc., to improve stability and conversion The effect of high efficiency and smooth combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

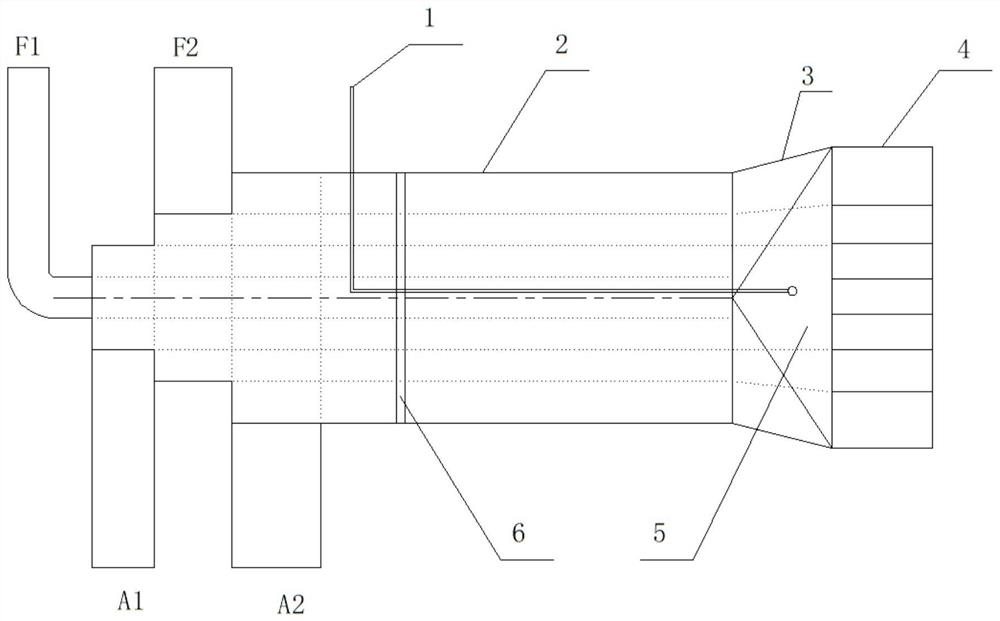

[0029] Such as Figure 1 to Figure 6 As shown, this example provides an ammonia gas burner, including a fuel inlet F1, a fuel inlet F2, an air inlet A1, an air inlet A2, an ignition device 1, a cylinder body 2, an expansion section 3, heat storage and stable combustion Body 4 and inner combustion chamber 5.

[0030] The cylinder 2 is provided with an igniter device 1 extending into the inner combustion chamber 5. The igniter device 1 is an existing structure well known in the art, and its connection with the cylinder 2 adopts a method well known to those skilled in the art. The existing connection mode of , will not be introduced in detail here.

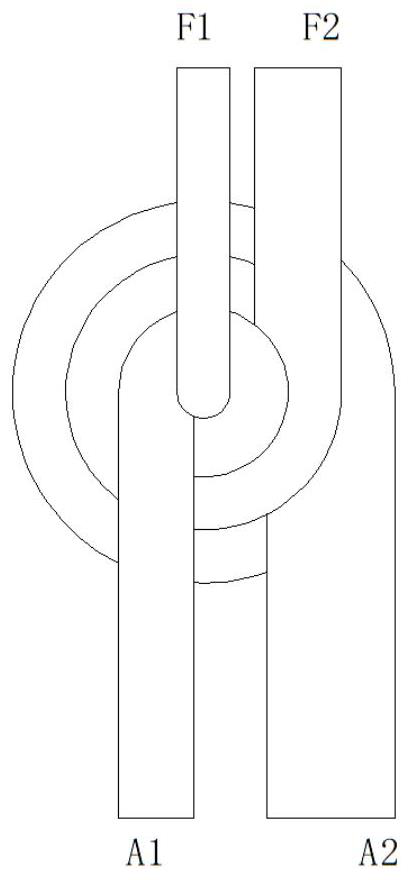

[0031] Such as figure 2 , the fuel inlet F2, the air inlet A1, and the air inlet A2 enter the cylinder along the tangential direction.

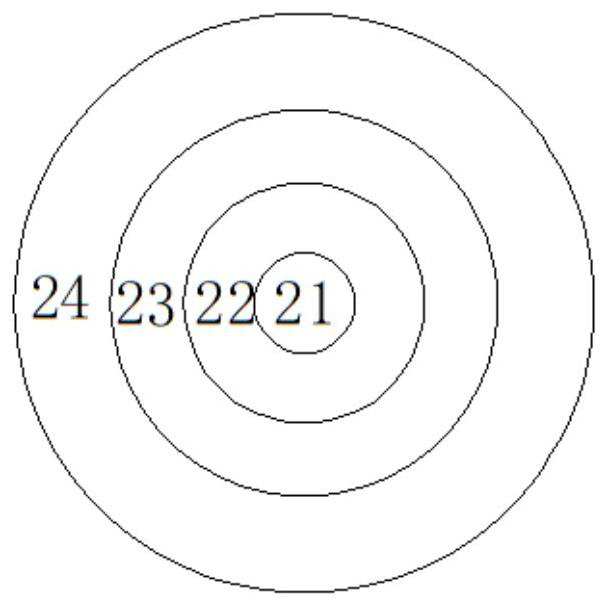

[0032] Such as image 3 , the barrel is divided into inner fuel passage 21, inner air passage 22, outer gas passage 23, outer air passage 24 from inside to outside, inner fuel passage 21, inner...

Embodiment 2

[0039] Such as Figure 7 , The heat storage and combustion stabilization body 4 is a circular mesh structure, the inside is a heat storage body, the outside is an outer air flow channel, and swirling blades are arranged in the outer air flow channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com