Colorimetry apparatus

A color measuring device, a technology of parallel light, applied in the direction of measuring device, color measuring device, color measurement using electric radiation detector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

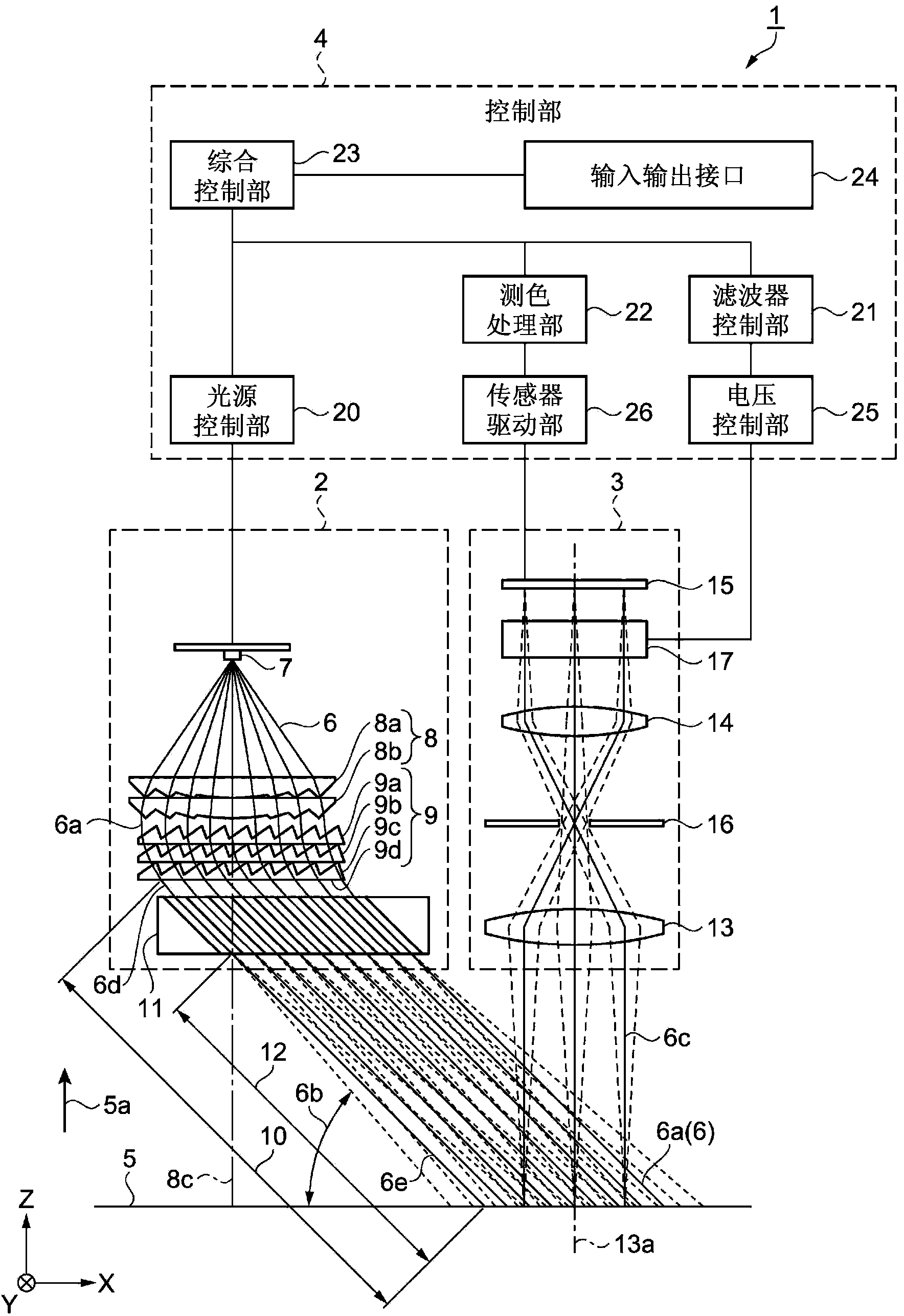

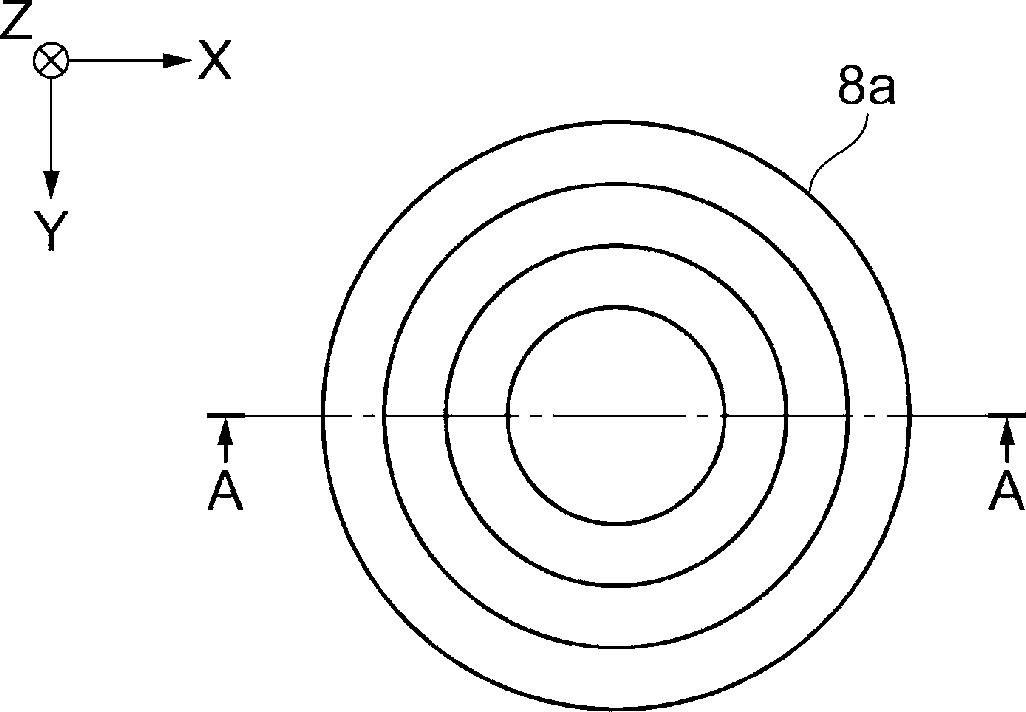

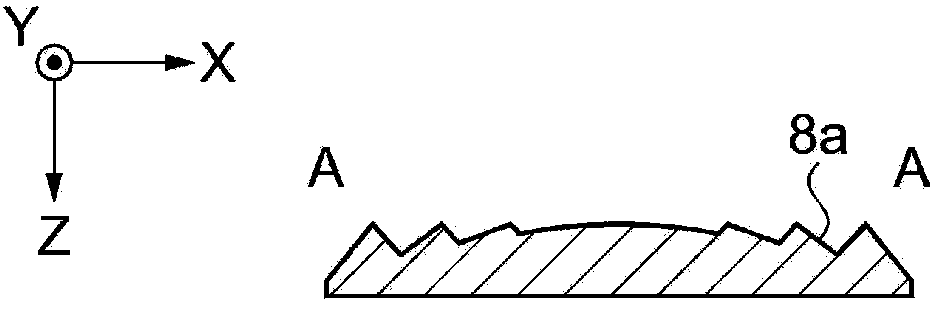

[0045] according to figure 1 ˜ FIG. 5 illustrate the colorimetric device according to the first embodiment. figure 1 It is a schematic configuration diagram showing the configuration of the colorimetric device. Such as figure 1 As shown, the colorimetric device 1 includes a light projecting unit 2 , an imaging unit 3 , and a control unit 4 . The light projecting part 2 is a part that irradiates the light 6 to the surface to be measured 5 . The imaging unit 3 is a part that receives the light 6 c reflected by the measurement surface 5 . The control unit 4 controls the light projecting unit 2 and the imaging unit 3 . The imaging unit 3 is provided at a position opposite to the position where the light projecting unit 2 irradiates the light 6 . The direction traveling from the light projecting unit 2 to the imaging unit 3 is set as the X direction. Furthermore, a surface to be measured 5 is provided at a position facing the light projecting unit 2 and the imaging unit 3 . ...

no. 2 approach

[0090] Next, an embodiment of a filter provided in a colorimetric device will be described using FIG. 6 . Fig. 6(a) is a schematic perspective view showing the structure of a filter. FIG. 6( b ) is a schematic perspective view showing the structure of the upper filter, and FIG. 6( c ) is a schematic perspective view showing the structure of the lower filter. This embodiment differs from the first embodiment in that the structure of the filter 11 is different. In addition, the description of the same points as those of the first embodiment will be omitted.

[0091] That is, in this embodiment, as shown in FIG. 6 , a filter 46 is used in the colorimetric device 45 . The filter 46 has the same function as the filter 11 in the first embodiment. In the filter 46 , a plate-shaped upper filter 48 is stacked on a plate-shaped lower filter 47 . As shown in FIG. 6( b ), the light transmitting portions 48 a and the light absorbing portions 48 b of the upper filter 48 are alternately ...

no. 3 approach

[0097] Next, an embodiment of the colorimetric device will be described using FIG. 7 . 7( a ) is a schematic plan view showing the structure of the colorimetric device, and FIG. 7( b ) is a schematic side view showing the structure of the colorimetric device. In addition, the description of the same points as those of the first embodiment will be omitted.

[0098] That is, in this embodiment, as shown in FIG. . Each of the first light projecting unit 52 to the fourth light projecting unit 55 has the same function as that of the light projecting unit 2 in the first embodiment. The first light projecting unit 52 is located on the Y-direction side of the imaging unit 3 , and emits parallel light 6 a onto the surface to be measured 5 at a position facing the imaging unit 3 . The second light projecting unit 53 is located on the X-direction side of the imaging unit 3 , and irradiates parallel light 6 a to the surface to be measured 5 at a position facing the imaging unit 3 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com