Abrasive particles, abrasive articles and methods of making and using the same

A technology of abrasive particles and abrasive products, applied in chemical instruments and methods, abrasives, manufacturing tools, etc., can solve problems such as increasing costs and restricting supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0152] All parts, percentages, ratios, etc. in the examples, as well as in the remainder of this specification, are by weight unless otherwise indicated. In the tables below, "nm" means not measured.

[0153] A summary of the various starting materials used to prepare the Examples is provided in Table 1 below.

[0154] Table 1

[0155]

[0156]

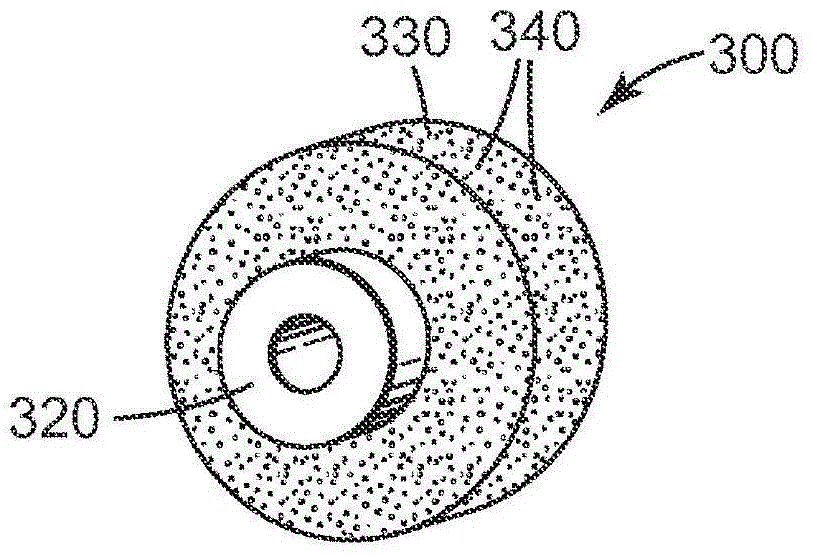

[0157] Disc preparation method

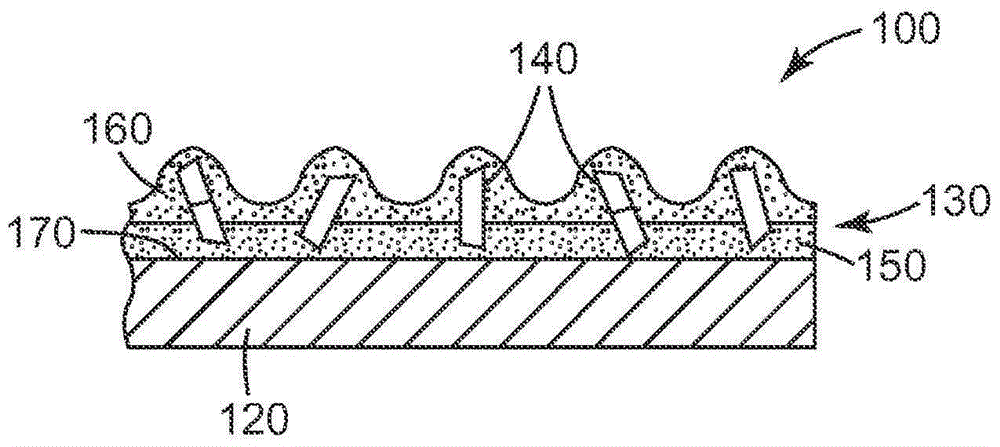

[0158] A disc with a 7 inch (17.8 cm) diameter and a 7 / 8 inch (2.2 cm) diameter mandrel hole backed with a vulcanized fiber thickness of 0.83 mm (33 mils) (obtained as DYNOS vulcanized fiber from Tross, Germany) DYNOS GmbH, Troisdorf, Germany) was coated with a 3.5 gram / disc (g / disc) primer composition consisting of 49.15 parts by weight of resole phenolic resin, 40.56 parts by weight of filler, 0.1 part of surfactant 1 and 10.19 parts by weight of water. Then the disk is electrostatically coated with abrasive particles of 15.0 g / disk, and then coated with a compounding composition of 13....

example 1

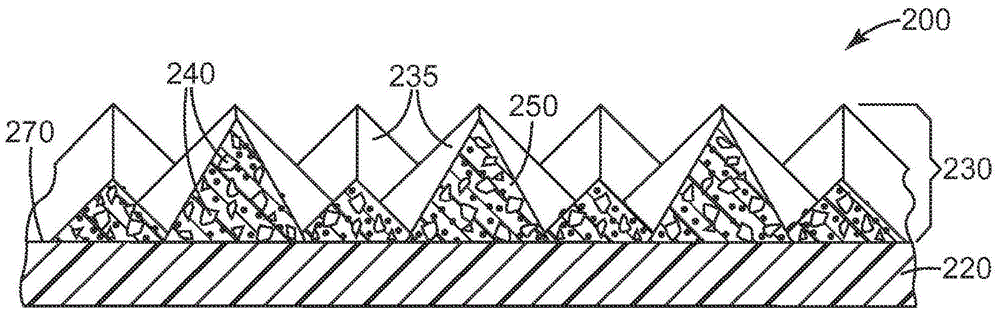

[0167] Example 1 is shaped abrasive particles prepared by alumina sol-gel without incorporation of seed crystals. The shaped abrasive particles of Example 1 were made by preparing a boehmite sol-gel using the following recipe: DISPERAL Alumina monohydrate powder (1600 parts by weight from Sasol North America). The resulting sol-gel was aged for at least 1 hour prior to coating. The sol-gel was forced into a production mold with a triangular mold cavity (28 mil (0.71 mm) deep, 110 mil (2.78 mm) on each side). The draft angle between the sidewalls and the bottom of the mold was 98 degrees. The mold was fabricated with 50% of the mold cavity having 8 parallel ridges rising from the cavity floor, which intersected one side of the triangle at a 90 degree angle, and the remaining cavity having a smooth bottom mold surface. The spacing of the parallel ridges was 0.277 mm and the cross-section of the ridges was triangular with a height of 0.0127 mm and an angle of 45 degrees betwee...

example 4-9

[0171] Example 4-9 was prepared in the same manner as Example 1, except that the composition of the modifying agent was changed and Fe was added 2 o 3 Seed crystals, and change the calcination conditions, are shown in Table 2. These examples containing beta-alumina were seeded and achieved much higher density and hardness. As noted in Table 3, the grinding performance exceeded the non-seeded Example 3 in all cases and met or exceeded the control disc in 2 cases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com