Splicing type plastic and wood flower box

A flower box, plastic wood technology, applied in container cultivation, horticulture, botanical equipment and methods, etc., can solve the problem that the plastic wood flower box cannot be combined and spliced, and achieve the effect of convenient production, cost saving and material cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

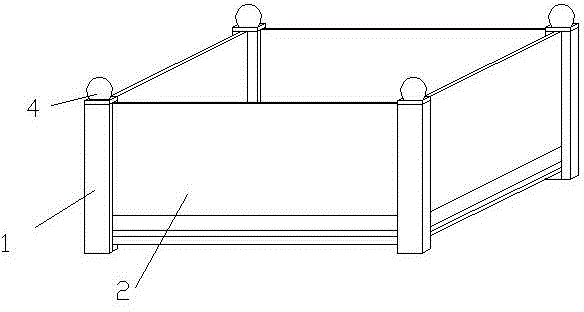

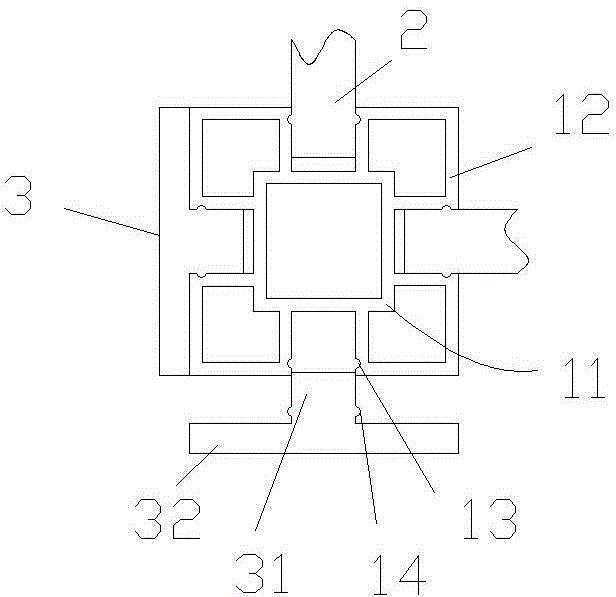

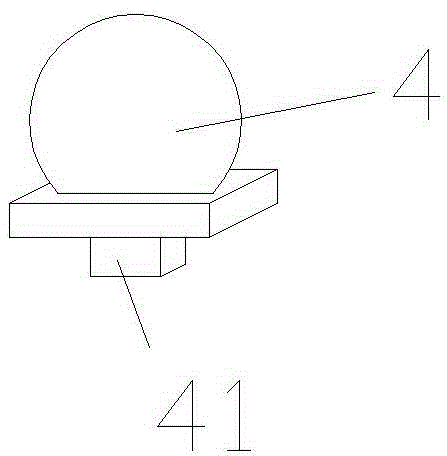

[0027] Embodiment 1: as figure 1 , figure 2 As shown, a splicable plastic-wood flower box includes four columns 1 and four surrounding edges 2 to form a square flower box. The column 1 includes a square inner column 11 and four square side columns 12, the four side columns 12 are connected to the four corners of the inner column 11, the inner column 11 is hollow to form a hollow hole, and the side columns 12 are also hollow structures . The inner column 11 and the side column 12 in the column 1 are integrally formed plastic wood materials. Two adjacent side columns 12 are spaced apart to form a slot, and one column forms four slots. Surrounding edges 2 are plugged into two adjacent slots, and decorative panels 3 are plugged into the other two slots. The decorative panel 3 is composed of a square socket part 31 and an exterior decoration part 32. The two sides of the square socket part 31 are provided with ribs 14, and the two sides of the slot are symmetrically provided w...

Embodiment 2

[0029] Embodiment 2: as Figure 5 , figure 2 As shown, a splicable plastic-wood flower box includes six columns 1, seven surrounds 2 and two base plates 5, forming a Japanese-shaped flower box, and the flower box is divided into two planting areas. The column 1 includes a square inner column 11 and four square side columns 12, the four side columns 12 are connected to the four corners of the inner column 11, the inner column 11 is hollow to form a hollow hole, and the side columns 12 are also hollow structures . The inner column 11 and the side column 12 in the column 1 are integrally formed plastic wood materials. Two adjacent side columns 12 are spaced apart to form a slot, and one column forms four slots. Among the four uprights on the four corners, surrounding edges 2 are plugged into two adjacent slots, and decorative panels 3 are plugged into the other two slots. The two columns in the middle are inserted with surrounding edges 2 in three slots, and a decorative pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com