Device and method for removing mercury from boiler flue gas of power station

A technology for power plant boilers and flue gas, which is applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of high operating cost, low investment cost, affecting the comprehensive utilization of fly ash, etc., so as to increase the residence time, improve the Efficiency of mercury removal and effect of reducing operating cost of mercury removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

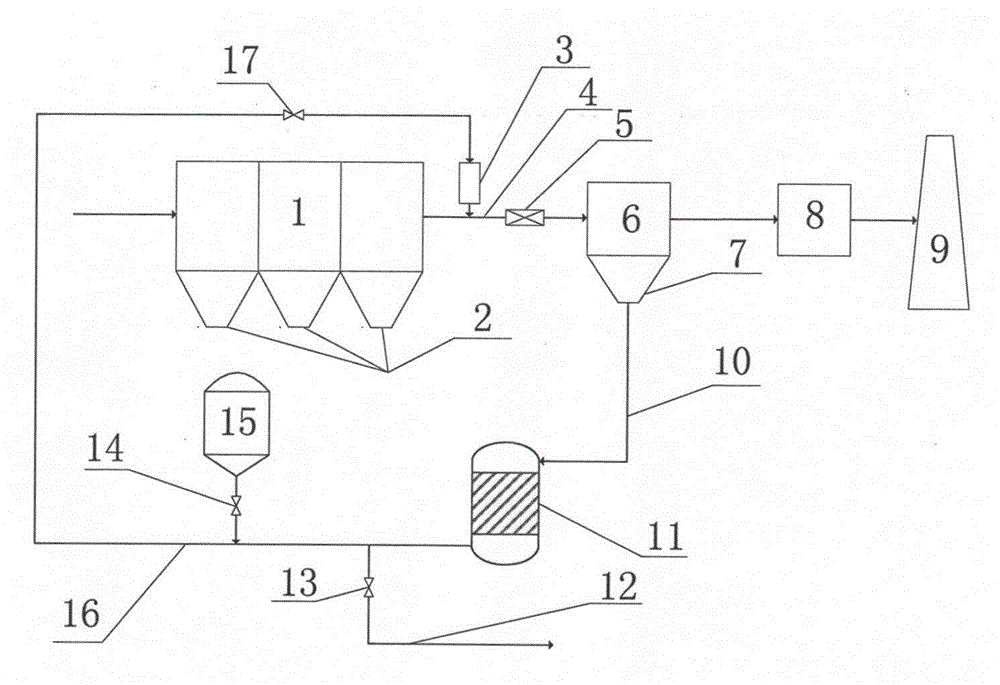

[0036] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0037] figure 1It is a schematic diagram of a device for removing mercury from flue gas of a power plant boiler provided by the present invention. After the flue gas comes out of the air preheater, it enters the electrostatic precipitator 1 for dust removal. The bottom of the electrostatic precipitator area is provided with a coarse ash hopper 2, which is removed by recycling the electrostatic precipitator. coarse ash and most of the fine ash. The adsorbent is sprayed into the adsorbent injection area 4 between the electrostatic precipitator 1 and the bag filter 6 through the adsorbent injection device 3, and a static mixer 5 is arranged in the adsorbent injection area 4, and the flue gas enters the static mixing After the device 5, the adsorbent is fully dispersed in the flue gas and adsorbs and removes mercury therein. Then th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap