Air hose connector for tight-lock coupler

A connector and tight-fitting technology, applied in the direction of pipes/pipe joints/pipe fittings, connections with fluid cut-off devices, passing components, etc., can solve problems such as inconvenient use and maintenance, low versatility of parts, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

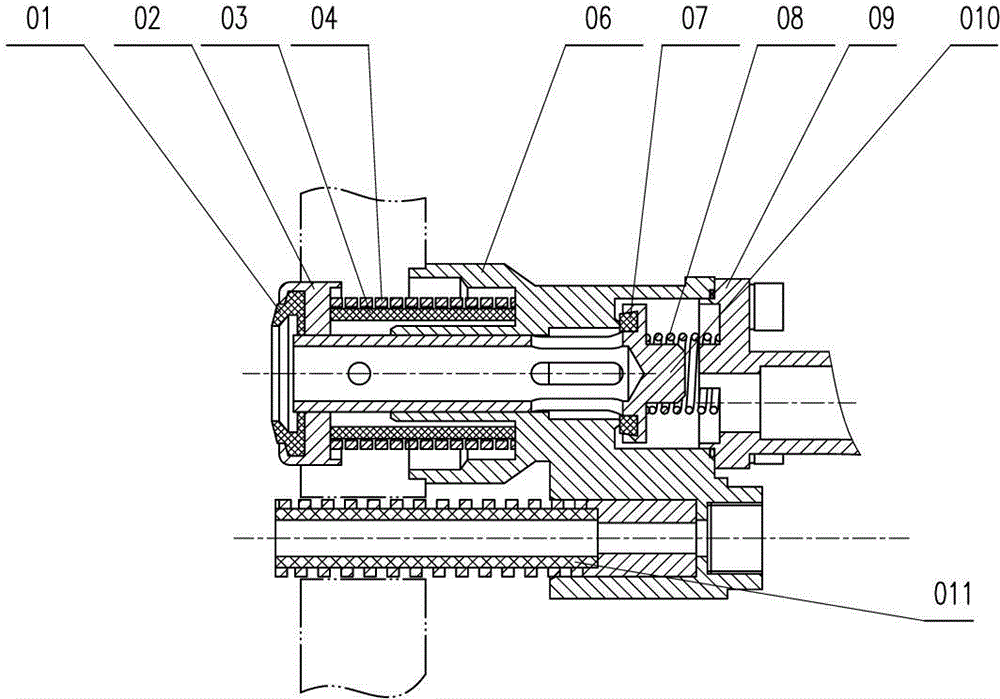

[0019] like figure 1 As shown, the air duct connector in the prior art mainly consists of valve body 06, valve head 02, tappet 010, gasket 07, pressure spring 04, tappet spring 08, valve port rubber 01, rubber tube 03, main air Tube 09, unhook tube 011, etc. The sealing structure inside the main air duct connector is composed of rubber tube 03, pressure spring 04 and valve body 06; The two ends are extruded together.

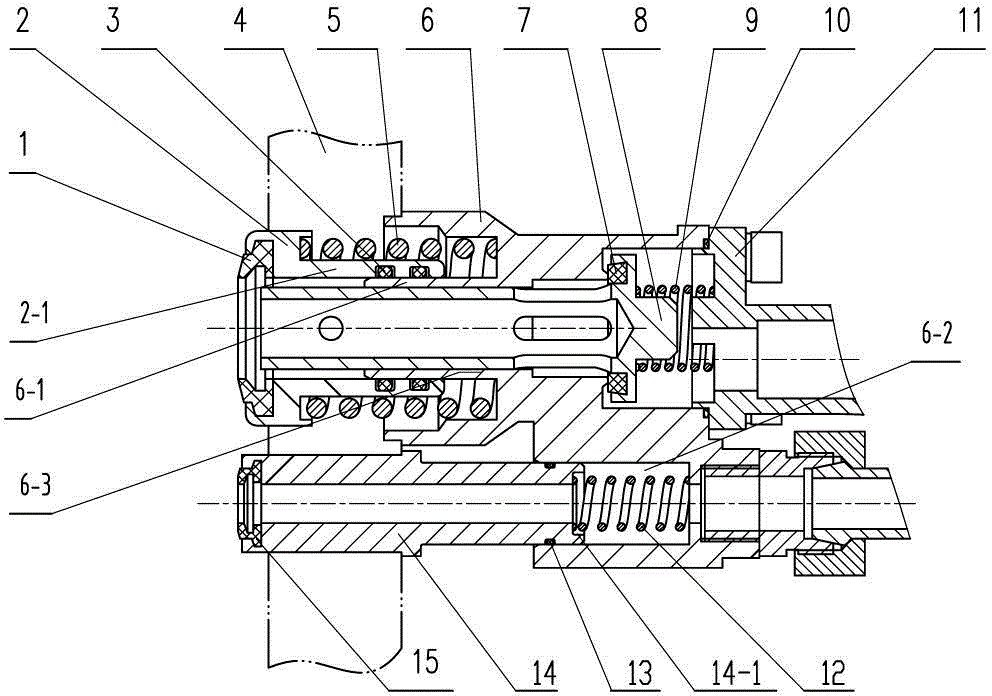

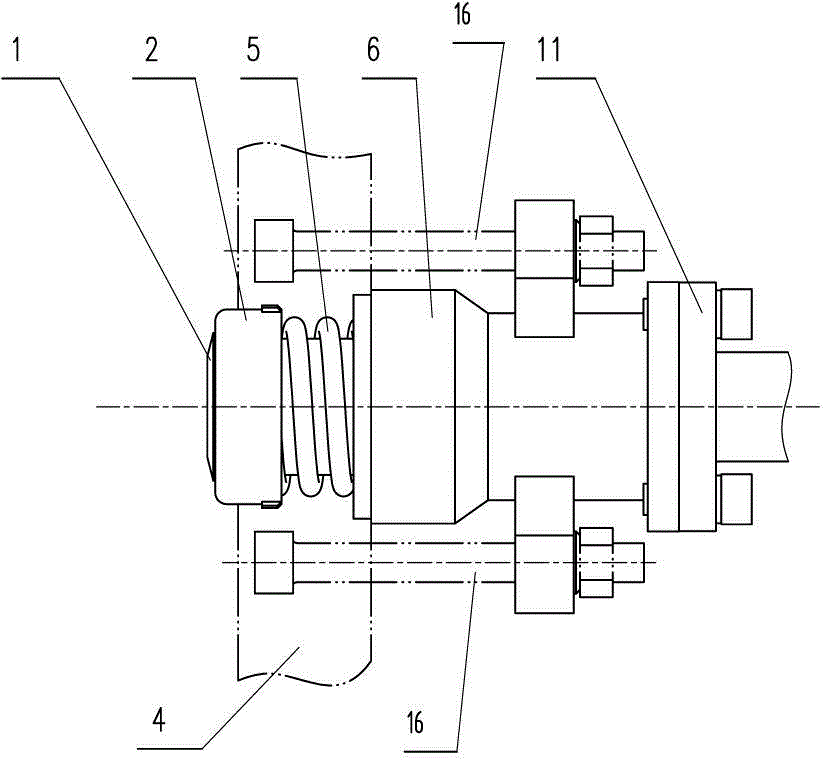

[0020] like figure 2 , 3 As shown, an air duct connector for a close-fit coupler of the present invention includes a valve port rubber 1, a valve head 2, a pressure spring 5, a valve body 6, a gasket 7, a tappet 8, a tappet spring 9, and a main air Pipe 11 and unhook pipe 14, the valve port rubber 1 is installed on the valve head 2, the shaft of the tappet 8 is slidingly fitted with the valve hole 6-3 of the valve body 6, and the gasket 7 is mounted on the tappet On the rod head of 8 and with the orifice of valve hole 6-3 on-off cooperation, one end of tapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com