Intelligent precision lighting energy saving method during plant cultivation by using artificial light and device thereof

A technology of artificial light and artificial light source, applied in lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve problems such as energy waste, and achieve the effects of reducing energy consumption, saving labor and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

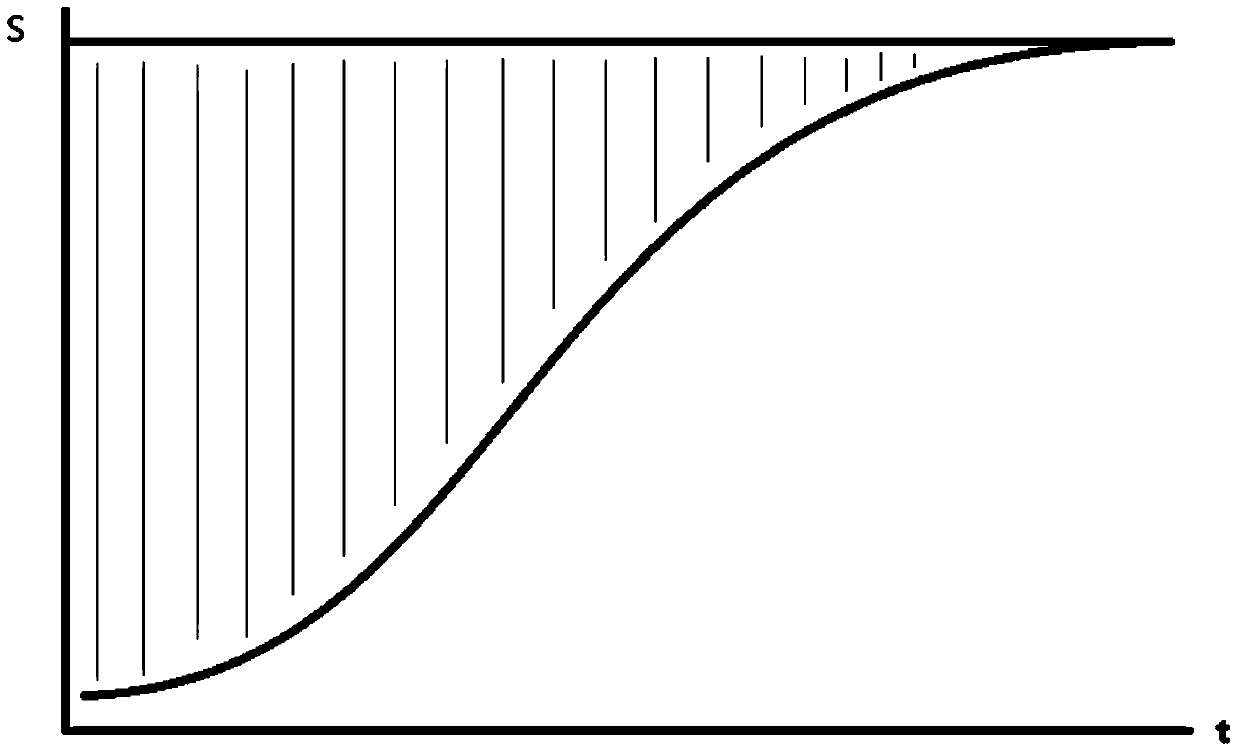

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

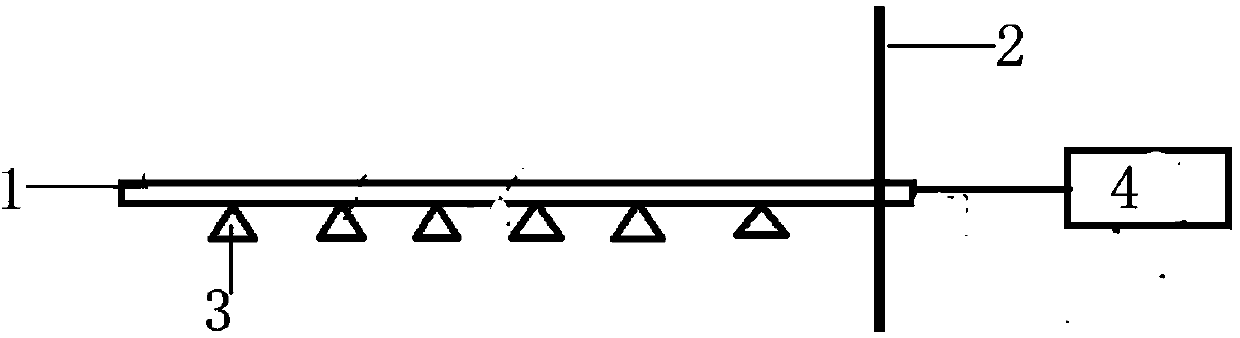

[0045] Embodiment 1 The device 1 of the present invention for the intelligent precise lighting energy-saving method for artificial light cultivation of plants

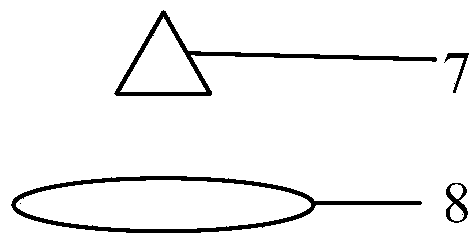

[0046] The structure diagram of the device for the intelligent precise lighting energy-saving method for plant artificial light cultivation in this embodiment is shown in figure 2 It is composed of a light source frame 1, a lifting mechanism 2, 24 light source-lens units 3 and a power source 4; the light source-lens unit 3 is divided into 4 rows and installed on the light source frame, 6 in each row. The structure diagram of the light source-lens unit 3 is shown in image 3 , Composed of artificial light 7 and a set of focusing lenses 8 arranged on it: the height of the light source frame 1 is adjusted by the lifting mechanism 2, and the power source 4 provides electric power for the artificial light source 7 in the light source-lens unit 3 and adjusts its light intensity .

[0047] The set of focusing lenses 8 used in the...

Embodiment 2

[0050] Embodiment 2 The device 2 of the present invention for the intelligent precision lighting energy-saving method for artificial light cultivation of plants

[0051] The structure diagram of the device for the intelligent precise lighting energy-saving method for plant artificial light cultivation in this embodiment is shown in Figure 5 It is composed of a light source frame 1, a lifting mechanism 2, 30 light source-lens units 3, a power source 4, a camera 5 and a control system 6; the light source-lens units 3 are installed on the light source frame in 5 rows, 6 in each row. The structure diagram of the light source-lens unit 3 is shown in Image 6 , Composed of artificial light 7 and a set of focusing lenses 8 arranged on it: the height of the light source frame 1 is adjusted by the lifting mechanism 2, and the power source 4 provides electric power for the artificial light source 7 in the light source-lens unit 3 and adjusts its light intensity The camera 5 is installed on...

Embodiment 3

[0055] Example 3 Using the device 1 for the intelligent precise lighting energy-saving method for artificial light cultivation of plants

[0056] Refer to Embodiment 1 for the device used in this embodiment for the intelligent and precise lighting energy-saving method for plant artificial light cultivation.

[0057] A total of 24 small rapeseeds were planted in 4 rows of 6×4 under the light source frame, and the position and the light source-lens unit 3 on the light source frame formed a one-to-one relationship.

[0058] Manual manual adjustment, the specific steps are as follows:

[0059] 1) When the canopy area of the small rapeseed plant is small, adjust the power supply to make the artificial light source smaller, adjust the lifting mechanism to make the light source stand and the plant canopy shorter (10cm), adjust the distance between the focusing lens and the artificial light source (5cm) ), so that the spot size (diameter 4cm) formed by the light emitted through the focusing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com