Clutch-brake combination mechanism

A combination mechanism and clutch technology, applied in the combination of coupling and brake, gear transmission mechanism, mechanical equipment, etc., to achieve the effect of high torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

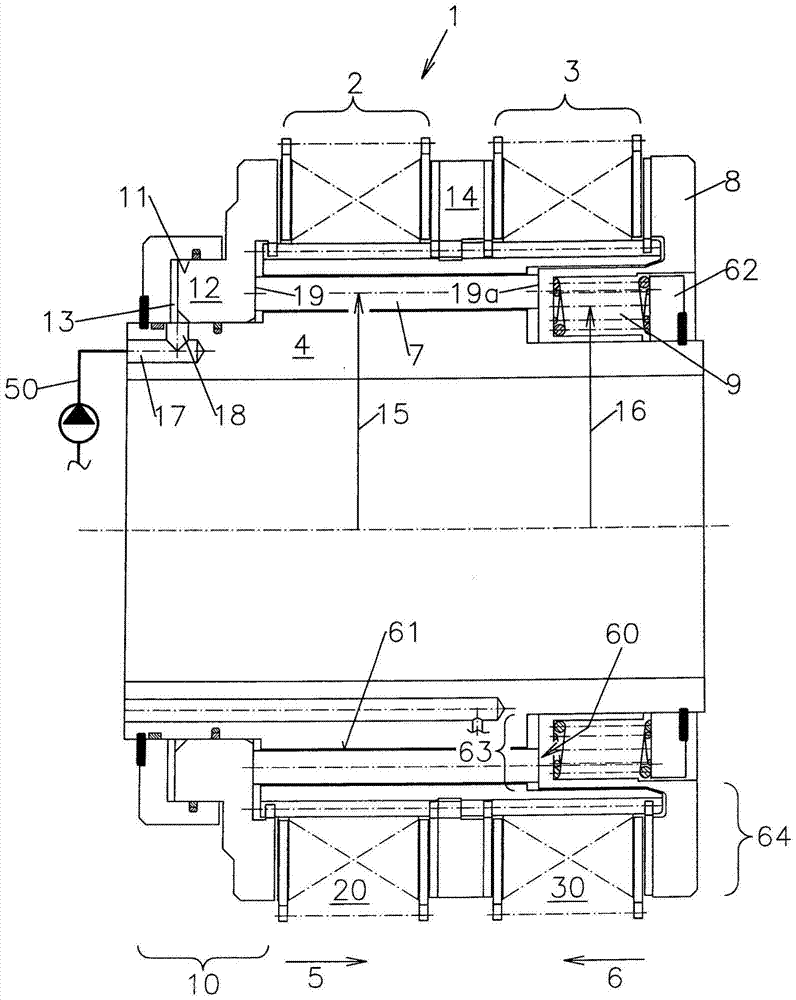

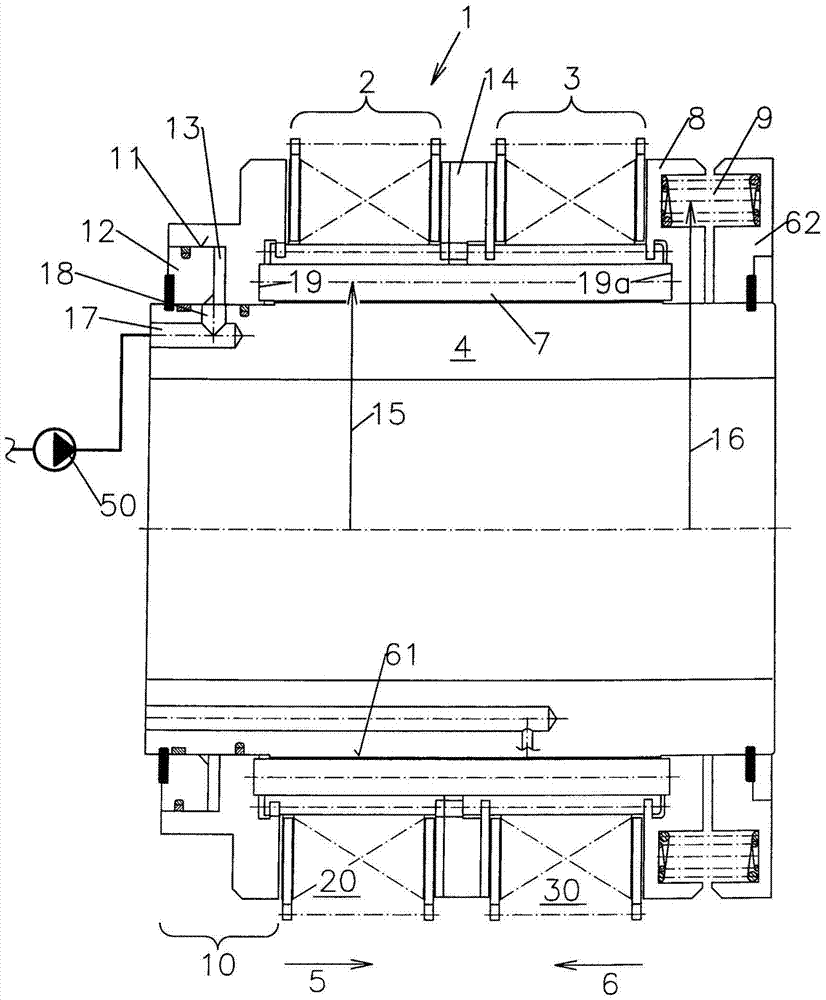

[0039] The figures show a clutch-brake combination 1 according to the invention.

[0040] At one end of the common carrier 4 there is a clutch disc pack 2 and at the other end of the common carrier 4 there is a brake disc pack 3 .

[0041] The clutch plates and brake plates are formed in the form of a ring and include teeth on their inner circumference by means of which the clutch plates and brake plates sit on corresponding teeth provided on the outer circumference of the carrier 4 and are thus axially The way to move is located on the outer periphery of the carrying device 4 .

[0042] The clutch 20 is acted upon by the piston-cylinder unit 10 in the closing direction 5 , and if the clutch is closed, the drive of the downstream mechanical components can then be brought about by the teeth of the clutch arranged on the outer circumference.

[0043] For this purpose, the piston-cylinder-unit 10 is equipped with an annular cylinder 11 which is spaced at a distance from the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com