Leaking-heaping resistant down jacket made of porous fabric

A technology for down jackets and fabrics, applied in clothing, clothing, protective clothing, etc., can solve the problems of down drilling, incomplete printing of marking units, and down piles, so as to prevent slipping out, avoid incomplete printing, and increase friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

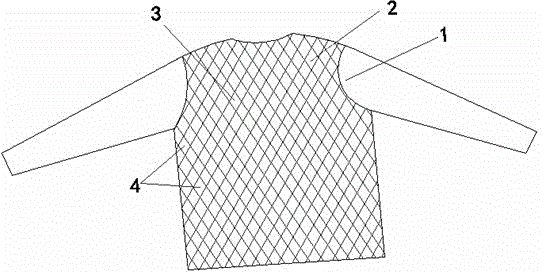

[0015] see figure 1 , an anti-drilling and anti-stacking porous fabric down jacket of the present invention, comprising a fabric 1, a lining 2 and an inner tank 3, the inner tank 3 is separated into many small diamond-shaped cavities 4 by sewing threads, and the rhombus-shaped cavities 4 are filled with Down, the side of the fabric 1 close to the inner tank 3 is suede-like, and the side of the lining 2 close to the inner tank 3 is suede-like.

[0016] The fabric 1 includes a substrate made of a porous fabric, the porous fabric also includes a bottom layer and an information layer, the bottom layer is directly formed on the substrate, the information layer is arranged on the bottom layer, the information layer includes a machine-recognizable pattern, and the machine-recognizable The pattern is formed by a plurality of marking units, the bottom layer is a dense film, and the pore size of the bottom layer is smaller than that of the marking units.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com