A kind of perforating unit ejector live connection

A technology of ejector and union, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of increasing material and machining time consumption, misalignment between the axis of the plug and the axis of the ejector, affecting the accuracy of the wall thickness of the finished product, etc. , to achieve the effect of reducing material consumption, simplifying on-site operations, and avoiding difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

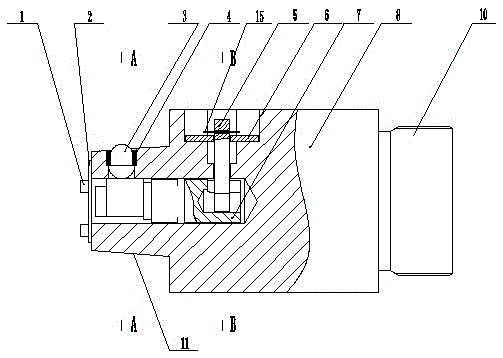

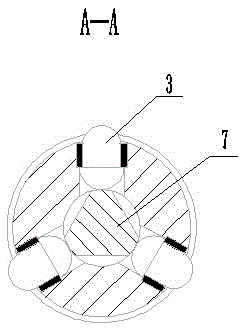

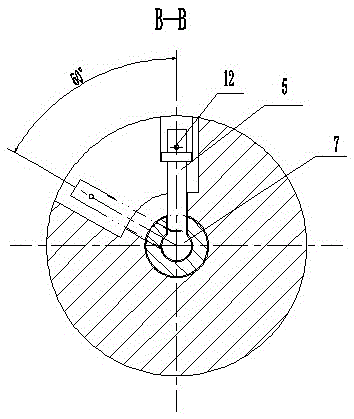

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0026] As shown in the figure, the ejector rod joint of a piercing unit according to the present invention includes a front cone 11, a middle base 8, and a rear screw 10. The middle of the front end of the cone 11 extends backward. There is a blind hole, the shaft 7 of the equilateral triangle is arranged in the blind hole, the width of the corner of the equilateral triangle is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com